Rotary pneumatic positioner F793

Installation and Maintenance Instructions

Pentair reserves the right to change the contents without notice page 2

Setting procedure

In most cases the positioner will be pre-set prior to leaving the factory. If readjustment is necessary,

follow the following instructions.

1. With the positioner correctly mounted to the actuator and cover removed, connect the air supply

and signal to the positioner.

2. Apply a of signal approximately 9 psig and gradually reduce this to 3 psig. If the actuator just

reaches the CLOSED position as the signal reduces to 3 psig, no adjustment is necessary.

3. If the actuator does not close fully at 3 psig, turn the hexagon zero adjusting nut 1/6 of a turn

clockwise and repeat step 2. Continue until zero is correctly achieved.

4. If the actuator reaches the CLOSED position before the signal reduces to 3 psig, turn the

hexagon zero adjusting nut 1/6 of a turn anti-clockwise and repeat step 2. Continue until zero is

correctly achieved.

5. Gradually increase the signal to 15 psig. If the actuator just reaches the OPEN position as the

signal reaches 15 psig, then no adjustment is necessary.

6. If the actuator does not reach the OPEN position at 15 psig, this is indicative of the spring rate

being too high. Loosen the grubscrew in the range adjustment collar, (see Fig. 3), hold the collar

stationary using a hexagon socket wrench, and turn the spring slightly clockwise. This will move

the actuator even further away from fully OPEN and the zero adjusting screw must be used to

achieve fully OPEN.

7. Conversely, if the actuator reached OPEN position before 15 psig, turn the spring slightly anti-

clockwise with respect to the rate adjusting collar. Again re-adjust the zero screw to achieve

exact fully OPEN.

The zero and range settings are highly interactive and steps 2 to 7 must be repeated until zero and

span are acceptable.

Note: In steps 3 to 7, clockwise and anti-clockwise rotations are as viewed from the adjusting nut

end of the spring.

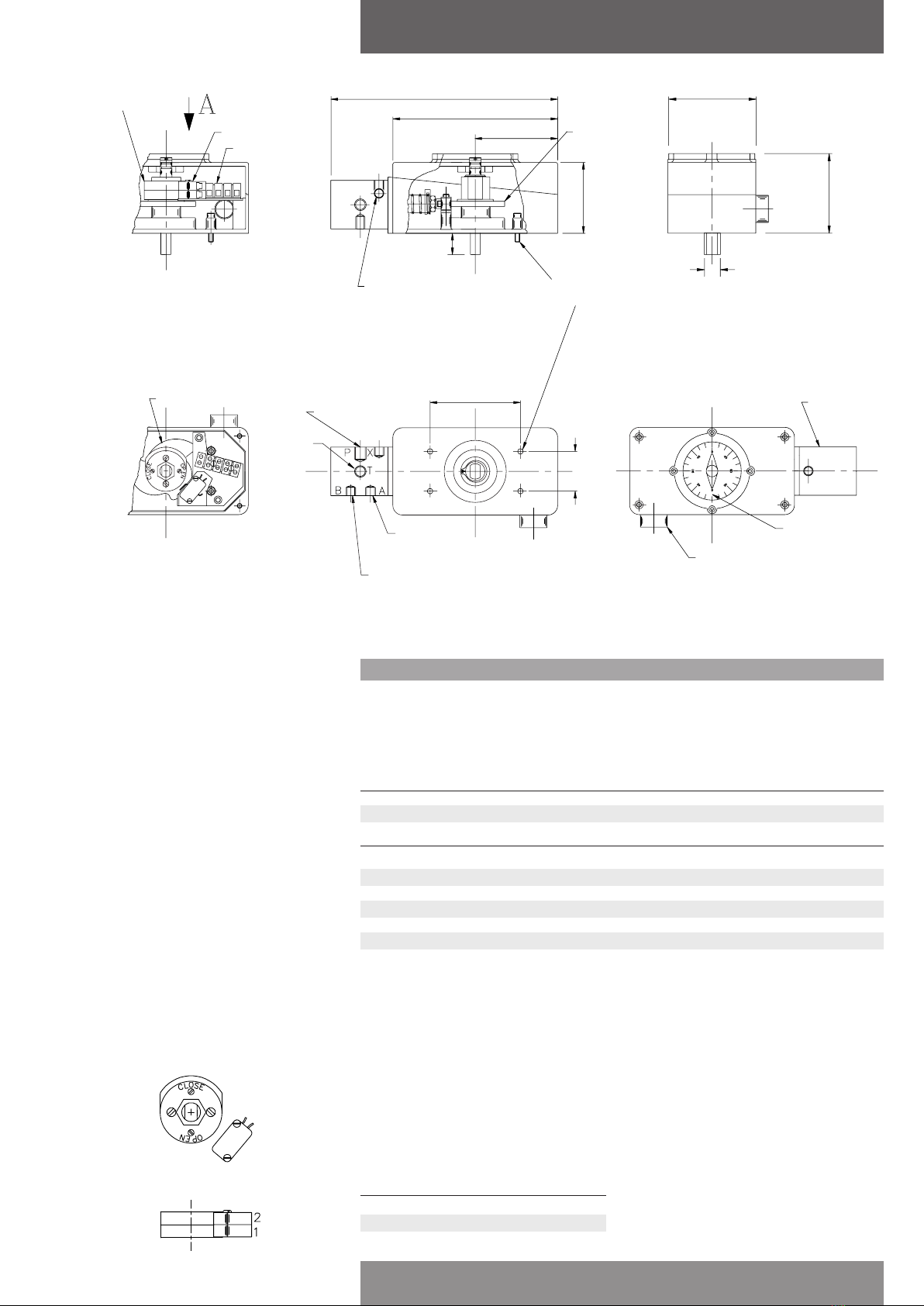

Figure 3

Figure 4 - Direct operation

Feedback

cam

Zero adjusting screw

Hexagonal socket

wrench

Grub screw

Hex lock nut

Range adjustment

collar

Cover fitting

Ensure that the actuator is in the position corresponding to minimum signal, ie. CLOSED for direct

operation (see Fig. 4) and OPEN for reverse operation (see Fig. 5).

1. Remove the position indicator cover and position indicator from the main cover.

2. Fit the main cover over the shaft and secure to the body using a captive screw in each corner.

3. Fit the position indicator to the double ‘D’ at the top of the shaft.

4. Fit the position indicator cover to the positioner cover so that the zero degree markings are

disposed along the transverse axis of the positioner. Before finally securing the position indicator

cover, ensure that the cover is positioned so that the arrow indicates the exact position of the

actuator.

Figure 5 - Reverse operation

Technical data

Input signal single range 3 - 15 psi (0.2 - 1.0 bar) standard.

split range 3 - 9 psi (0.2 - 0.6 bar) 9 - 15 psi (0.6 - 1.0 bar).

cam characteristics linear

3 - lobe cam: curve 1, range: 3 - 15 psi = 90° movement.

curve 2, range: 3 - 9 psi or 9 - 15 psi = 65° movement.

curve 3, range: 3 - 15 psi = 65° movement.

other characteristics on request.

Supply media compressed air or gas, dry, dust and oil free with 5 filter element to inlet.

supply pressure 30 - 100 psi (150 psi max.) 2 - 8 bar (10 bar max.).

air consumption 0.6 cfm in balanced condition with 60 psi (4 bar) supply.

Environmental environmental temperature -5° to +160°F (-20° to +70°C).

mounting and mounting position as required. No limitations.

connections mounting kit universal mounting kit for Fig.790/796 series actuators.

air connections supply and output 1/4” BSP, signal 1/8” BSP

Materials of housing anodised aluminium alloy (stainless steel optional).

construction diaphragm nitrile rubber

valve spool stainless steel

cover anodised aluminium alloy (stainless steel optional).

Weight 4 lb. (1.85kg)

Options gauges instrument air 0 - 30 psi (0 - 2 bar) - 1 off.

supply air 0 - 150 psi (0 - 8 bar) - 2 off.

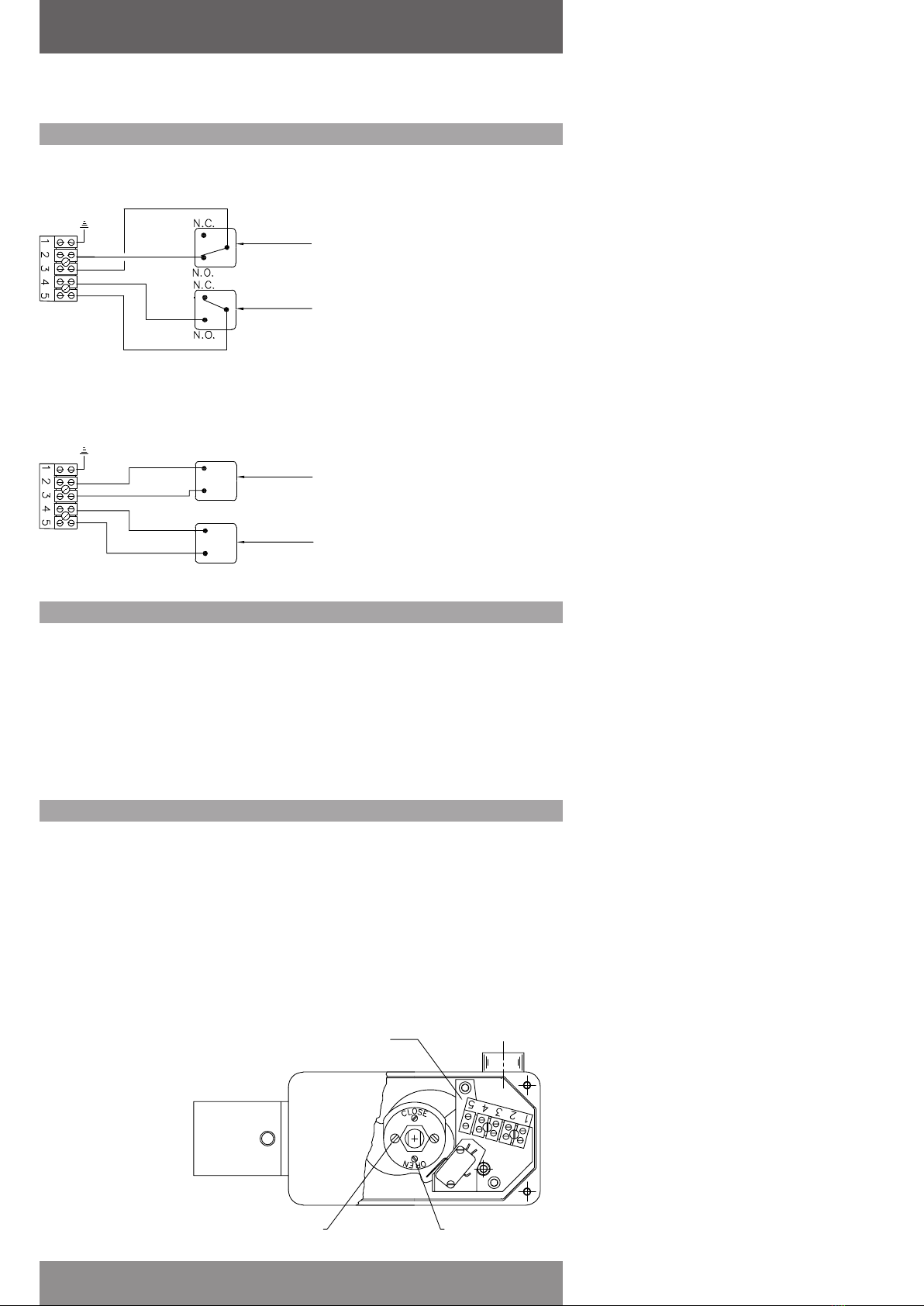

integral limit switches single pole double throw 10A 240V AC

inductive proximity sensors type NT2-V3-N.

Warning!

When Pressure Gauge is not required, fit

hex head socked screw from mounting kit

using proprietary none hardening sealing

compound or tape. If there is a requirement

to remove the socket screw for future

application, an applied torque of 200 lbs/ins

should not be exceeded.