7

inspect the seal cavity in the bracket for

burrs or nicks which could damage the seat

of the seal. Apply a film of soap paste or flax

soap (do not use oil or grease) to the seal seat

and install, taking care to seat it evenly and

squarely.

NOTE: If it is not possible to insert seat with fingers,

place cardboard protecting ring furnished with seal

over lapped face of seat and press into place with a

piece of tubing having end cut square. The tubing

should be slightly larger than the diameter of the

shaft. Remove cardboard after seat is firmly in

place.

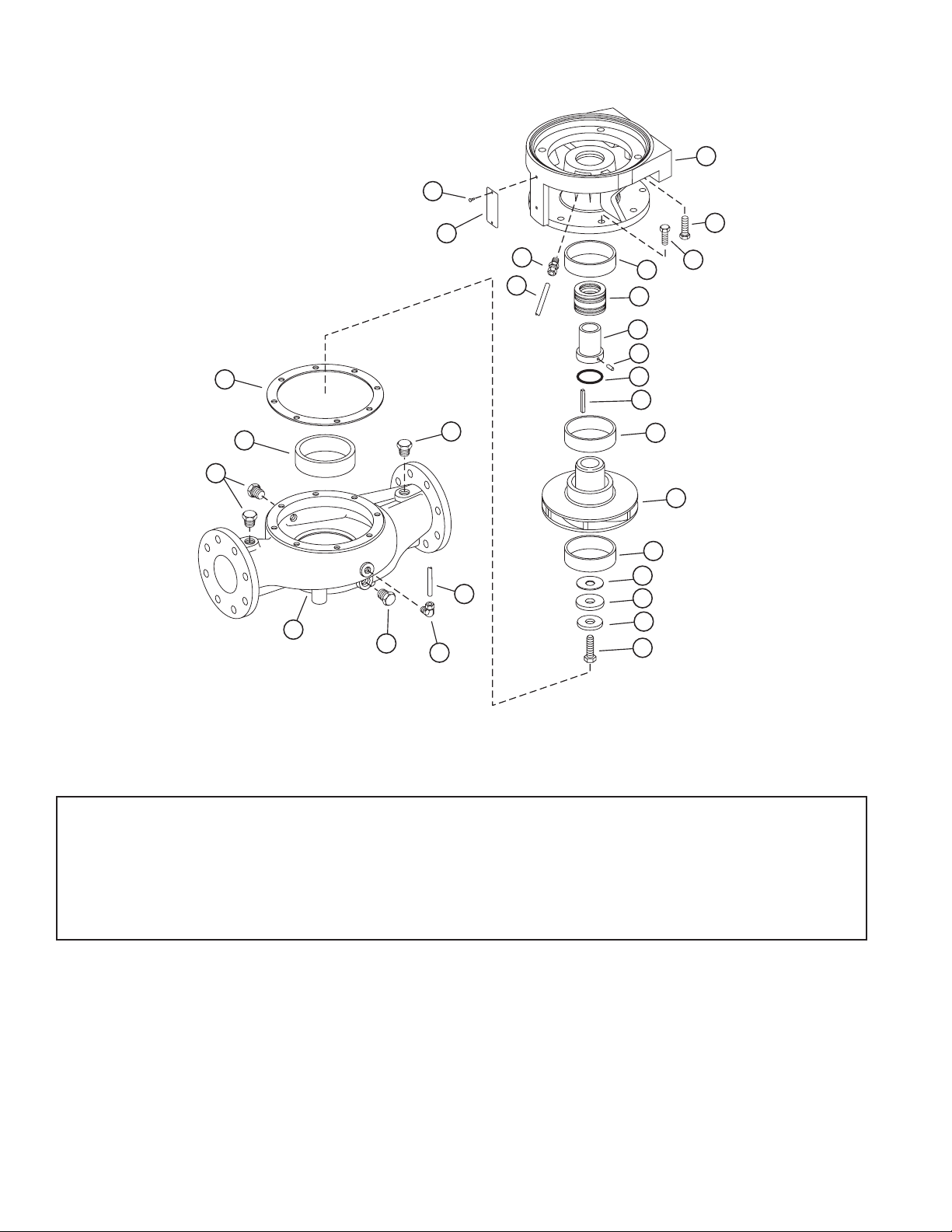

2. Position bracket (35) on the motor and secure

with capscrews (32). Tighten screws evenly to

assure properalignment.

3. If nameplate (34) was removed, install and

attach with screws (33).

4. Wipe the sealing faces of the seat and seal

washer clean. Oil these surfaces with a clean

light oil. Lightly oil the shaft sleeve (25).

Slide the entire rotating assembly onto the

sleeve. The shaft sleeve with the seal rotating

assembly on it may now be replaced on the

motor shaft. Spring tension will probably

prevent the sleeve from remaining in position

axially until the impeller is locked against it.

5. Press wearing ring(s) (7 & 16) in casing (6) and

bracket (35). Rings should not be hammered

into place. Use a press, or clamp the parts in

a bench vise, using wooden blocks to protect

the rings. It may be necessary to pin or dowel

the rings after assembly if the insert or casing

has had rings replaced before, since each

reassembly can stretch or tear metal and

thereby loosen the fits. If the facilities are

available, it is good practice to take a very

light finish cut or to ream the inside diameter

of the casing rings after pressing to restore

roundness. When rings are pressed, they may

get squeezed out of shape.

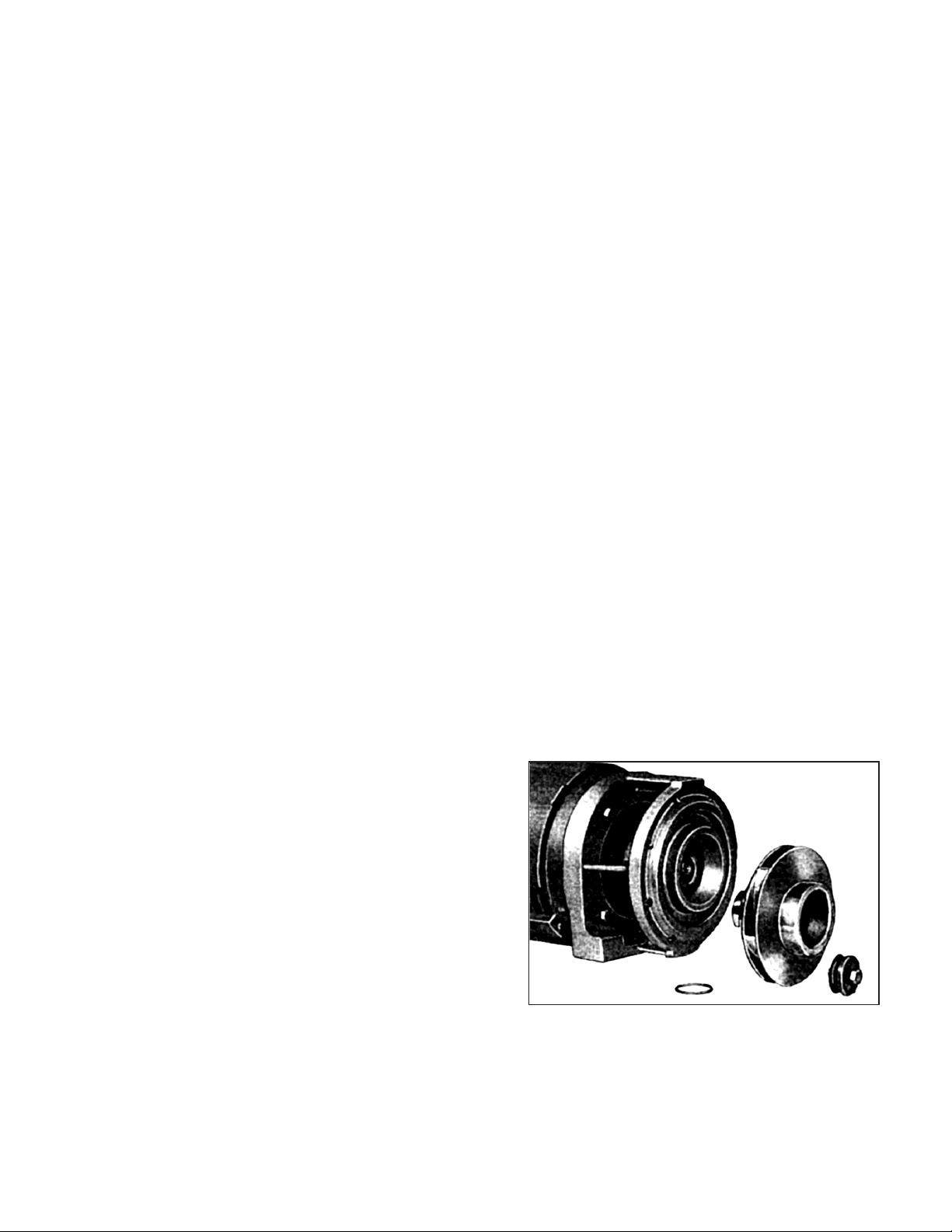

6. Place impeller wearing rings (optional – 14 and

15) on impeller (11), using the same care as for

the case wearing rings. If the rings are to be

trued on a lathe, do not clamp the impeller so

tightly that it is permanentlydistorted.

7. Carefully place gasket (10) on motor end of

impeller. Assembly key (12) and impeller (11) to

motor shaft. Secure impeller with gasket (9B),

washer (9A), and impeller screw (9).

8. Install the four pipe plugs (4) in the pump

casing. Position the gasket (8) and casing (6)

against the motor bracket and secure with

screws (5).

9. Replace all relief, cooling, flushings, or drain

lines from the pump including compression

connections (1 and 2) and tubing (3). Connect

discharge piping and suction piping if

required, making sure to install gaskets on

the flanged connections. Connect electricity

to motor.

10.Read starting instructions before attempting

to start pump.

STARTING PUMP AFTER REASSEMBLY

Do not start pump until all air and vapor has been

bled and until making sure that there is liquid in

the pump to provide the necessary lubrication.

Without the fluid around it, the seal may be ruined

in a few seconds of operation. It is possible that

the mechanical seal may drip during the first few

minutes to one hour of operation.