2 3

Engineering Data

MA-240L........................................................... 3

MA-240L-HD ..................................................... 4

MA-240M.......................................................... 5

MA-240M-HD .................................................... 6

MA-240K .......................................................... 7

SC-300L ........................................................... 8

SC-300 ............................................................. 9

RO-358L ......................................................... 10

RO-358........................................................... 11

Dimensional Data ...........................................12–13

Installation, Operation, Lubrication, Maintenance

and Storage Instructions....................................... 14

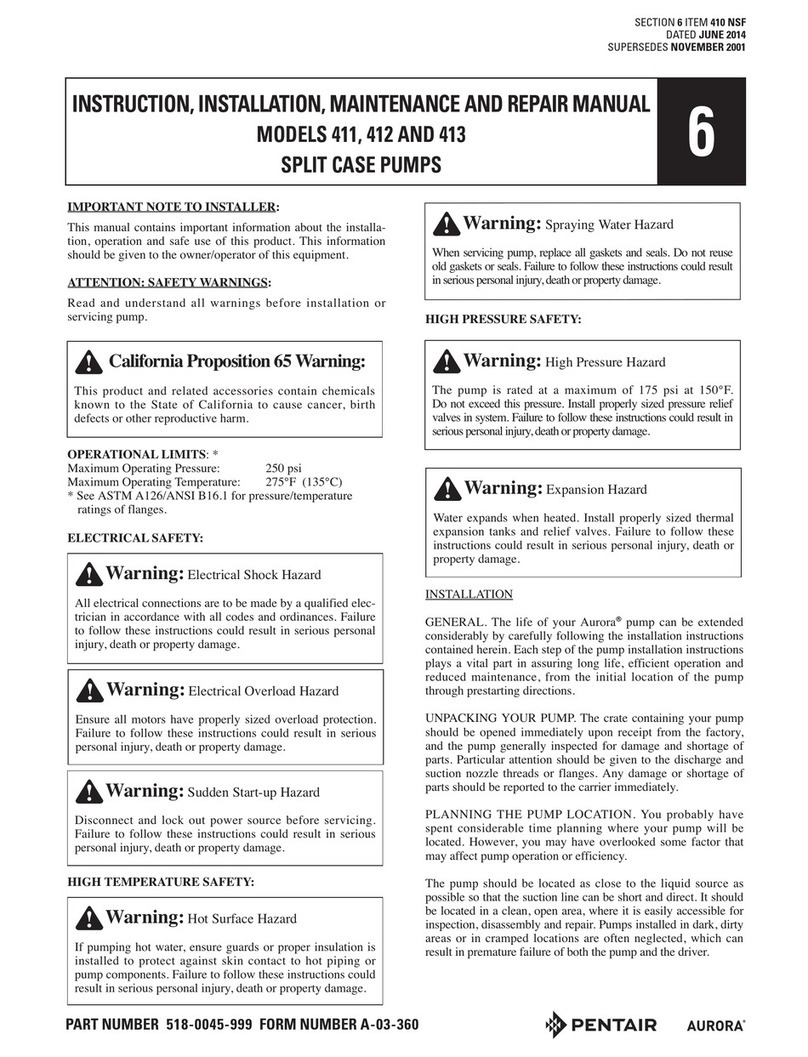

Safety ............................................................. 14

Storage............................................................ 14

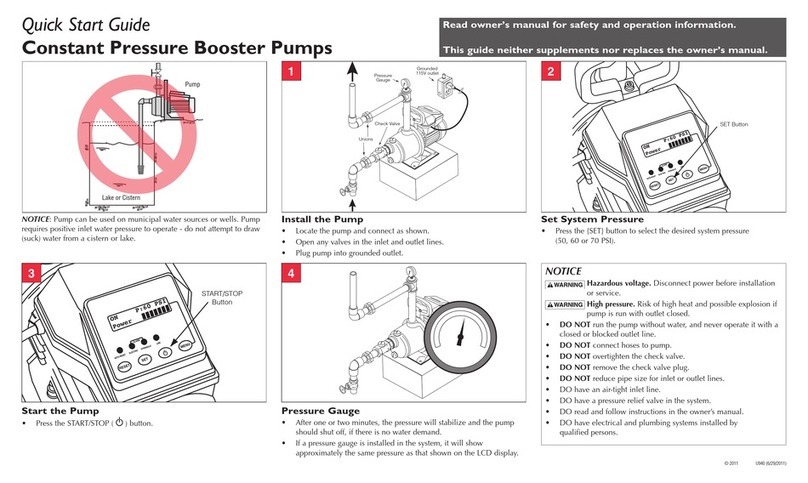

Pump Location and Piping Design...................... 14

Suction Piping.............................................14–15

Acceleration Head ............................................ 15

Discharge Piping .............................................. 15

Bypass Piping .................................................. 15

Lubrication ...................................................... 16

V-Belt Drive ..................................................... 16

Direction of Rotation......................................... 16

Automatic (Safety) Shutdowns........................... 16

Suggested Piping System for Plunger Pumps ...... 17

Crankshaft Assembly............................................ 18

General ........................................................... 18

Tapered Roller Bearings .................................... 18

Cup Installation................................................ 18

Center Bearings................................................ 18

Installing Crankshaft ............................................ 18

Shim Adjustment of Tapered Roller Bearings....... 18

Installation of Crankshaft Oil Seal ...................... 18

Lube Oil Pump Assembly .................................. 19

Disassembly..................................................... 19

Connecting Rod, Crosshead, Extension Rod, Crosshead

Pin and Wiper Box Assembly/Disassembly .............. 19

General ........................................................... 19

Installing Wrist Pin Bushings............................. 20

Pinning the Crosshead ...................................... 20

Order of Assembly ............................................ 20

Precision Crankpin (Crankthrow) Bearings......20–21

Oil Scoop......................................................... 21

Wiper Box Assembly............................................. 21

General ........................................................... 21

“Poly Pak” Seal ............................................... 21

Mechanical Oil Seal.......................................... 21

Inserting the Extension Rod............................... 21

Stuffing Box, Packing and Plunger Assemblies ....... 21

General ........................................................... 21

Spring Loaded Packing ................................21–22

J-Style Stuffing Box & Plunger Assembly

(Styles 838 and 858) ....................................... 22

Inserting the Plunger ........................................ 22

Installing the Gland .......................................... 22

Installing the Stuffing Box................................. 22

Connecting the Plunger..................................... 23

Packing ........................................................... 23

Plungers.......................................................... 23

Disc Valve Systems and Abrasion Resistant

Valve Construction ............................................... 23

General ........................................................... 23

Disc Valve and Abrasion Resistant

Setting the Valve Seat....................................... 23

Installing O-Rings, Abrasion Resistant Spring

and Cage ......................................................... 23

Installing Disc, Spring, Disc Valves and Stem...... 24

Pulling the Valve Seat ....................................... 24

Salvage of Worn Seats....................................... 24

Trouble Location and Remedy ..........................25–27

Parts Lists......................................................28–34

Warranty ............................................................. 36