03/19/15

5410, 5420, 5440 Solids Handling Pumps

Installation, Operation and Maintenance

8

Fairbanks Nijhuis®

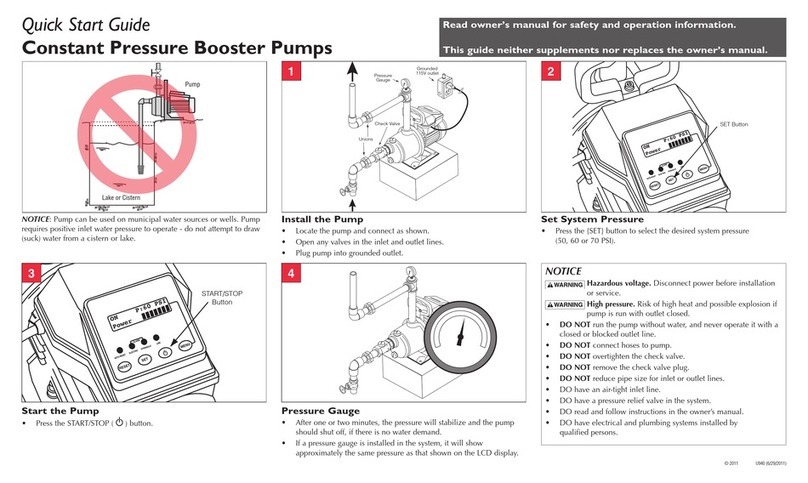

PIPING: CAUTION:

All piping connections must be made with the pipe in a free supported state, and without the need to apply

vertical or side pressure to obtain alignment of the piping with the pump flange.

All piping should be independently supported near the pump so the pipe strain will not be transmitted to the

pump casing. Weight of the pipe and contained liquid must be considered in support design. Suction and discharge

piping should be one or two sizes larger than the pump suction and discharge sizes, especially where piping is

of considerable length. Flexible joints installed in the piping must be equipped with tension rods to absorb piping

axial thrust.

Suction pipe must be airtight and sloped upward to the pump flange to avoid air pockets which will impair

satisfactory pump operation. Discharge pipe should be as direct as possible with a minimum of valves to reduce

pipe friction losses.

A check valve and closing valve should be installed in the discharge line and a closing valve in the suction line.

The check valve, between the pump and closing valve, protects the pump from water hammer and prevents reverse

rotation in the event of power failure. Closing valves are used in priming, starting and when the pump is shut down.

Pumps must never be throttled by use of a valve in the suction line.

AUXILIARY PIPING CONNECTIONS:

In addition to primary piping connections, your pump may require connections to the water seal ring, stuffing box

drain, baseplate drain, discharge pressure gauges or mechanical seals (if provided). All these connections should

now be installed. (Refer to Mechanical Seal section of this manual.)

NOTE: For satisfactory pump operation and life, auxiliary pipe lines must be kept clean.

ROTATION:

Before connecting the motor to the pump, bump start the driver and verify rotation is in the proper direction. Correct

pump rotation is indicated by a directional arrow on the pump casing.

VIBRATION AND NOISE LEVELS:

After installation is complete and the pump is put into normal service, a baseline measurement of noise and vibration

levels should be made for future reference. Periodic checks should be made, as changes in either of these could

indicate problems. Early detection can save expensive repairs and downtime. Refer to Troubleshooting in the

operation section of this manual for simple causes and remedies.

Vibration and noise level measurements should be made with the equipment in its normal operating mode, with no

unusual background noise present.

INSTALLATION 5410:

LEVELING OF THE PUMP:

Lower the pump onto the foundation and position the base so the anchor bolts are

aligned in the middle of the holes in the base.

Set the base on metal shims or metal wedges placed directly under the part of

the base carrying the greatest weight, and spaced close enough to give uniform

support and stability.

Adjust the metal shims or wedges until the shaft of the pump is vertical. Make

sure that all shims or wedges fit firmly between the foundation and the base.

If leveling nuts are installed on the anchor bolts and are used for alignment, follow

the same procedure as with shims or wedges. Support the base with additional

shims or wedges if necessary. Make sure that all nuts and shim are in firm contact

with the base.

Tighten the foundation bolts snugly, but not too firmly and with a good quality

machinist’s level check that the shaft is vertical in two vertical planes. Refer to the

Grouting section.