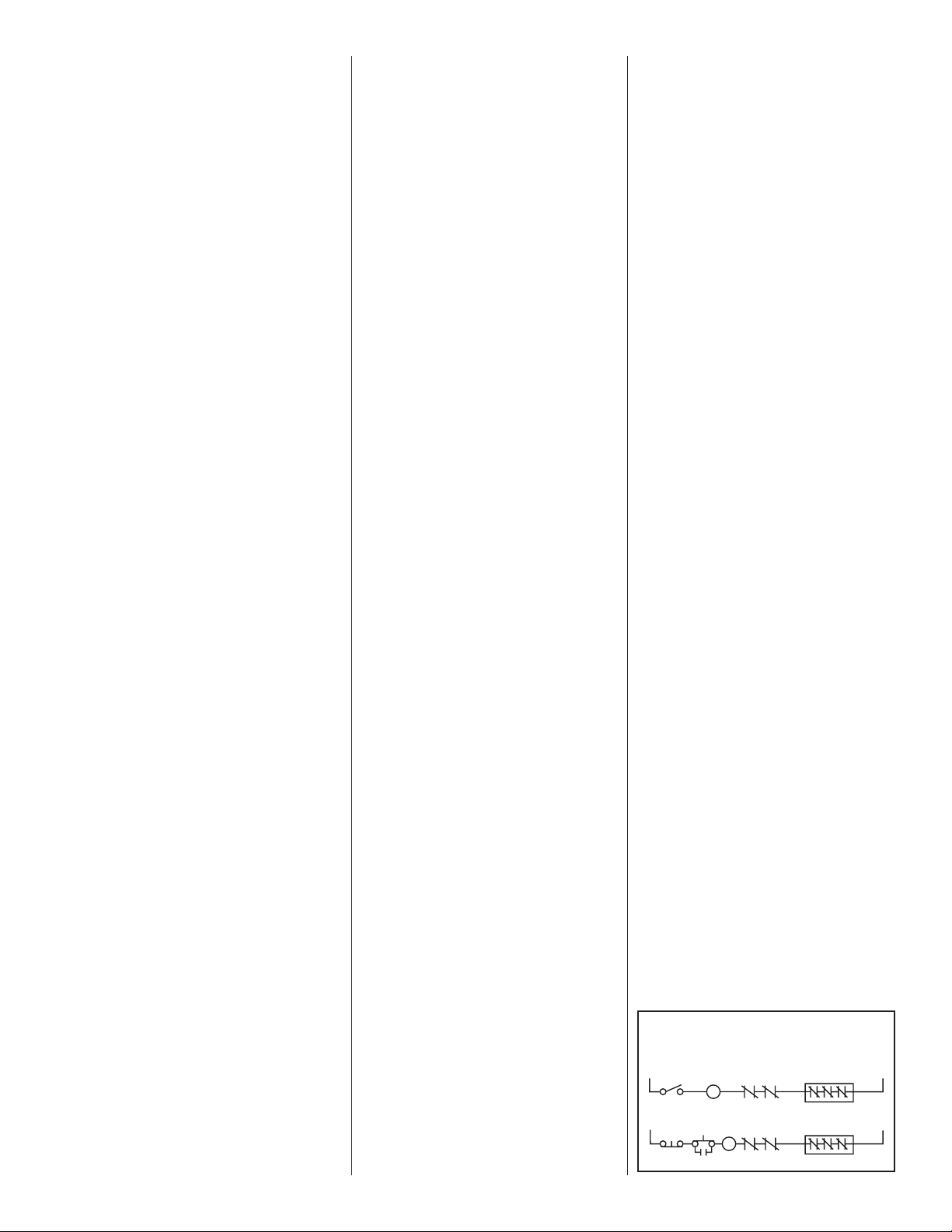

WARNING

BLACK

COIL

ON-OFF

SWITCH

L1 THERMOSTATS

IN SERIES

WHITE

L2

TWO WIRE CONTROL OFFERING AUTOMATIC RESET

THERMOSTATS

IN SERIES

WHITE

L2

BLACK

THREE WIRE CONTROL OFFERING AUTOMATIC RESET

L1

COIL OL OLSTART

IN CERTAIN APPLICATIONS THE NEC MAY REQUIRE THREE OVERLOAD RELAYS

WARRANTY IS VOID IF HEAT SENSORS ARE NOT

CONNECTED AS SHOWN (IN SERIES WITH CONTACTOR OIL)

notice operation. If pump is

noisy and vibrates, rotation

is wrong. To change rotation

interchange any two line

leads to motor on 3ø only.

DO NOT INTERCHANGE

MAIN INCOMING LINES. If

duplex system, check second

pump in the same manner.

4. Now set both H-O-A switches

to Auto position and allow

water to rise in sump until one

pump starts. Allow pump to

operate until the level drops to

turn-off point.

5. Allow sump level to rise to

start other pump. Notice run

lights on panel; pumps should

alternate on each successive

cycle of operation.

6. Turn both H-O-A switches

to Off position and allow sump

to fill to the override control

level.

7. Turn both switches to Auto

position and both pumps should

start and operate together until

level drops to turn-off point.

8. Repeat this operation cycle

several times before leaving

job.

9. Check voltage when pumps

are operating and check the

amp draw of each pump.

Check amps on each wire

as sometimes a high leg

will exist. One leg can be

somewhat higher, 5 to 10%,

without causing trouble. For

excessive amp draw on one

leg, the power company should

be consulted.

Phase Converters:

Phase converters are generally

not recommended, but in cases

where only single phase current is

available phase converter can be

used. Be sure to size the phase

converter large enough for the

amp draw specified on the motor

nameplate, not necessarily by motor

horsepower. The warranty on all

three phase submersible motors is

void if operated with single phase

power through a phase converter

and 3 leg ambient compensated

extra-quick trip overload protectors

are not used.

Pump

Maintenance

NOTE: Any unauthorized field

repair voids the warranty, the

hazardous location rating, and

Factory Mutual approval.

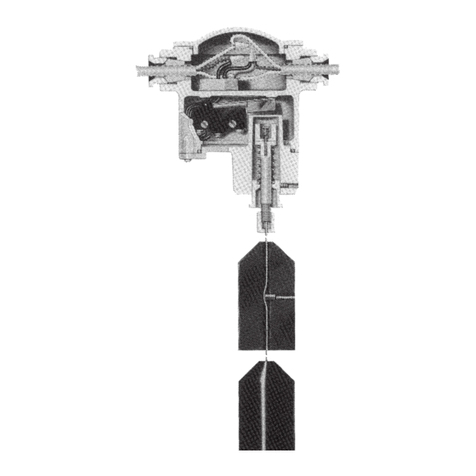

If the heat sensor and seal failure

are hooked up properly, no

attention is necessary as long

as the seal failure indicator

light doesn’t come on. To ensure

continuity of the seal sensor

leads, a test light is provided on

intrinsically safe Hydromatic

panels as standard equipment.

Pump should be checked every

quarter for corrosion and wear.

Maintenance:

As the motors are oil filled, no

lubrication or other maintenance is

required.

If the pump is used on a rail

system, it should be lifted once

every six months and checked for

corrosion and wear.

Generally these pumps give very

reliable service and can be expected

to operate for years on normal

sewage pumping without failure.

Lightning:

In some areas where considerable

lightning occurs, it is recommended

that a lightning arrestor be installed

at the control panel.

Lightning arrestors are good

insurance against damage to an

expensive motor.

Field Service on Motor:

All submersible motors out of

warranty can be serviced in

5

the field by any reliable motor

service shop. Any pump, in

warranty, must be returned to the

factory for service or repaired

at an authorized Hydromatic

service center. Charges will not be

allowed if in warranty pump is not

taken to an authorized Hydromatic

service center.

When field service is performed on

a pump, these instructions should be

carefully followed.

Field Service on Hydromatic

Hazardous Location Pumps:

If a Hydromatic hazardous location

pump is used in a hazardous location,

or if the pump is still in warran-

ty, the pump must be returned to

the factory for service or repaired

at an authorized Factory Mutual

Hydromatic service center. Charges

will not be allowed if in warranty

pump is not taken to an authorized

Factory Mutual Hydromatic service

center. This will ensure the integrity

of the hazardous location rating

of the pump and comply with our

warranty requirements.

Replacing Stator:

1. If stator only is damaged,

it may not be necessary to

completely dismantle pump as

stator and housing can be lifted

from pump without disturbing

seals or bearings.

2. Drain all oil from upper

housing, remove drain plug in

bottom of stator housing and

remove plug in top of housing

to allow air to enter.

3. After chamber is drained,

remove hold-down bolts and

lift off. Use care in lifting

as the seal failure connecting