2

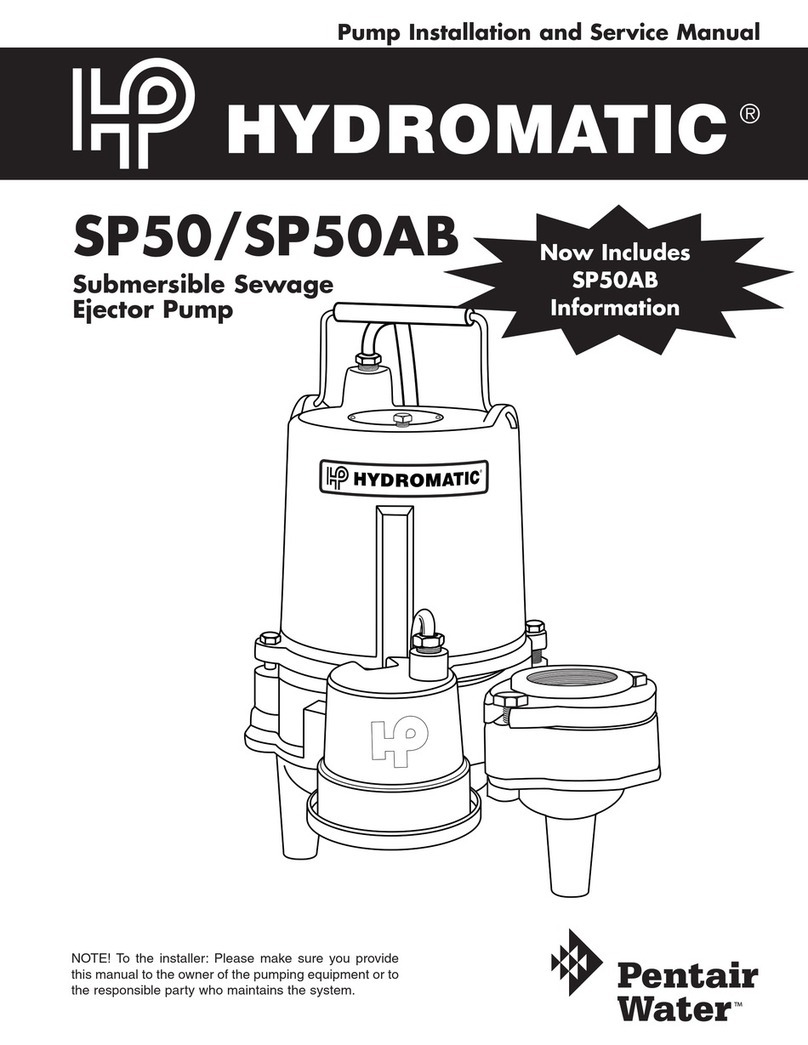

Thank you for purchasing your

Hydromatic®pump. To help

ensure years of trouble-free

operation, please read the

following manual carefully.

Before Operation:

Read the following instructions

carefully. Reasonable care and

safe methods should be practiced.

Check local codes and

requirements before installation.

Attention:

This manual contains important

information for the safe use of

this product. Read this manual

completely before using this

product and refer to it often for

continued safe product use.

DO NOT THROW AWAY OR

LOSE THIS MANUAL. Keep it in

a safe place so that you may refer

to it often.

Unpacking Pump:

Remove pump from carton. When

unpacking unit, check for

concealed damage. Claims for

damage must be made at the

receiving end through the delivery

carrier. Damage cannot be

processed from the factory.

WARNING: Before handling

these pumps and controls,

always disconnect the power

first. Do not smoke or use

sparkable electrical devices or

flames in a septic (gaseous) or

possible septic sump.

Pumps Not Operating or

in Storage:

Pumps with carbon ceramic seals

must have impellers manually

rotated (6 revolutions) after

setting non-operational for 3

months or longer and prior to

electrical start-up.

Pump:

The S4S/SB4S submersible

pumps are supplied for 1 and 3

phase and for 200, 230, 460 or

575 volts. Pump is supplied with

15 feet of power cord. Longer

cable lengths can be furnished

but must be specified at time of

order. Power cable is 4 wire with

the green wire for ground. Be sure

green wire is connected to a

ground lug in the control panel

and the control panel must be

connected to a ground rod or

ground wire from supply service.

NOTE: All single phase pumps

require properly sized start

capacitor, start relay and run

capacitor in the panel.

Sump Level Control:

Sump level is controlled by

Hydromatic 3900 mercury switch

level controls. The 3900 level

controls is a metal case

mercury switch sealed in a solid

polyurethane float. The float is

held in position by a weight

attached to the power cord above

the float. The cord supports the

float and is adjusted for height

from the surface.

Typical duplex systems use three

floats: the lowest float turns the

pumps off, the next higher float

starts the lead pump, the next

higher float (override) starts the

lag pump. The pumps alternate

on successive cycles.

General

Information

Two pumps operate together only

if sump level rises to the third or

override float. The override float

also brings on the second pump in

case of failure of the first pump.

Extra floats with appropriate

controls can be supplied for alarm

functions. Triplex systems use

four floats. The fourth highest

float brings on the second lag

pump. Three pumps operate

together only if sump level rises to

the fourth float (second override).

This float also brings on the third

pump in case of failure of either or

both of the first two pumps.

Alarm Controls:

The alarm float is usually set

above the override level so

the alarm will signal only if the

override level is exceeded.

However, some engineers prefer

to have the alarm float set below

the override level as it is possible

for one pump to fail and the other

pump to operate on the override

level with the sump level never

reaching the alarm level. This is

particularly true in cases of low

inflow capacity.

Electrical Control Panel:

It is recommended that the

Hydromatic control panel be used

with all pumps as proper start

components and pump protection

are furnished.

NOTE: All single phase pumps

require properly sized start

capacitor, start relay, and run

capacitor in the control panel.

IMPORTANT: If Hydromatic

control panel is not used and the

motor fails because of improper

components, the motor guarantee

is void.