23833A665 11/08/12 2

USAGE

The MRG20 is a submersible wastewater grinder

pump designed specifically for individual residential

applications. The pumps are to be used for domestic

sewage only and are not to be used for pumping

commercial or industrial sewage such as motels,

schools, apartments, factories, etc. THIS PUMP IS

NOT FOR USE IN HAZARDOUS LOCATIONS!

INSPECTING PUMP

Before making any piping or electrical connections,

check the pump for shipping damage or cracks.

Using a flat screwdriver placed in the slot on the

shaft end, turn shaft and impellers to be sure they are

free. DO NOT TURN IMPELLER WITH FINGERS AS

EDGES ARE SHARP.

POWER SUPPLY

The MRG20 grinder pump should be connected only

to a 230 volt, single phase, 60 Hz power source.

The pump will draw approximately 9.1 amperes at

minimum flow and 15.0 full load amperes. The pump

must be connected to a grounded power socket. DO

NOT cut off the ground pin from the power cord plug.

POWER CORD

A power cord is attached to the grinder pump via

three insulated quick-disconnect terminals.

The power cord should be replaced if it has

been damaged in any way or the cord jacket

has become brittle.

MOTOR TYPE

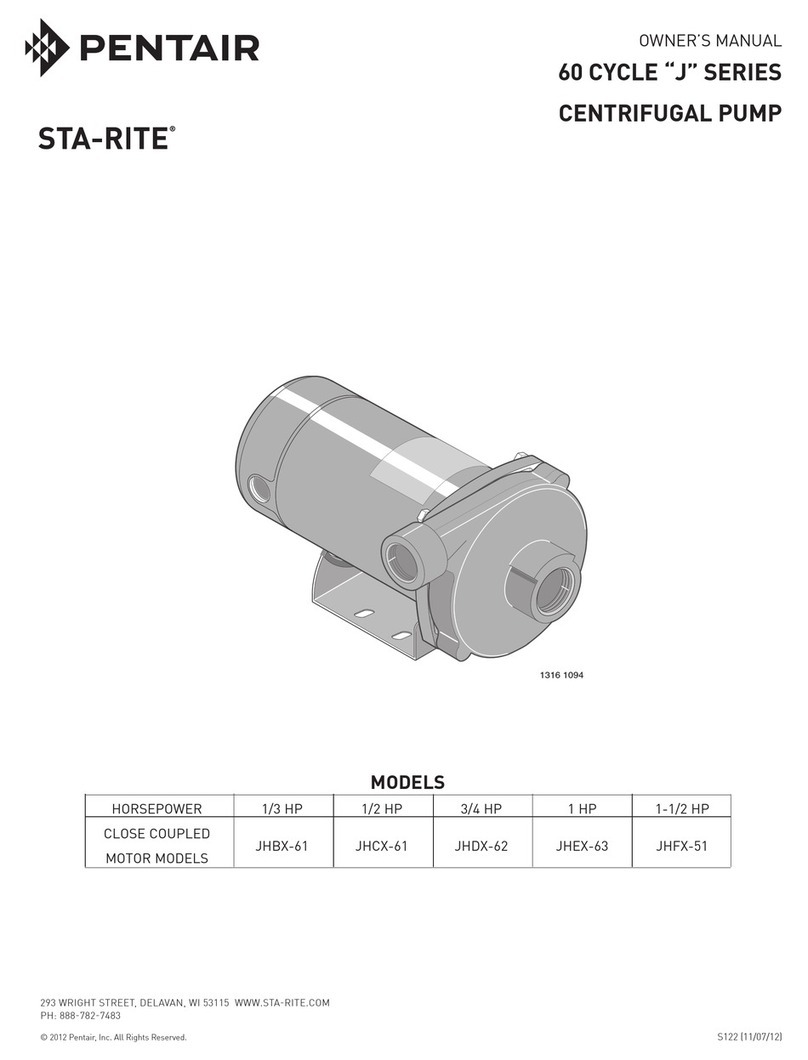

The MRG20 grinder pump contains a 3/4 frame, 2

HP, single phase, 60 Hz, 3450 RPM, capacitor start

- capacitor run motor with Class F insulation and

built-in on-winding overload protection. Motor has

upper and lower ball bearings and is oil-cooled and

lubricated.

nCAUTION!

THE MRG20 GRINDER PUMP SHOULD NEVER BE

WORKED ON WITHOUT FIRST DISCONNECTING

THE POWER CORD.

OIL TYPE

The motor housing contains dielectric transformer oil

to provide good heat transfer and lubrication of ball

bearings; no other lubrication is required. Oil level

may be checked by removing the nut and washers

from the top of the motor housing. The oil level

should be 3-7/8" from the boss with pump setting

vertically. Do not overfill with oil. Only dielectric

transformer oil obtained from a Myers authorized

service center should be used.

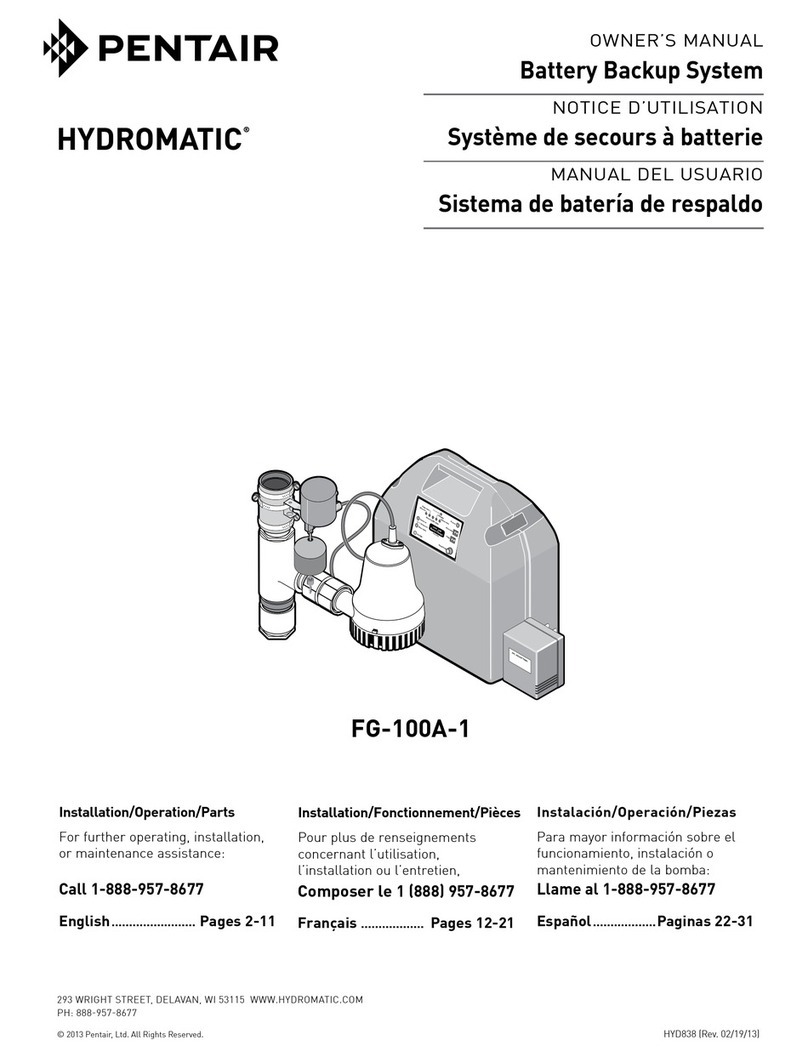

PUMP SWITCH INSTALLATION

INSTRUCTIONS

Mounting the Switch

1. Determine pumping range for installation. Do not

tether less than 3-1/2" from pipe.

2. Tighten strap around discharge pipe,

keeping switch cable between strap and pipe

to prevent slippage.

3. Space small ties at least 1" apart. To readjust ties,

press small tie tabs down.

4. To lock releasable tab, run remaining

strap between tab and head. Tuck strap

back through head.

Piggyback Plug Install

nElectrical outlet must not be located in

pump chamber.

nElectrical outlet voltage, piggyback plug voltage,

and pump voltage must match.

1. Follow steps 1 through 4 of “Mounting the Switch.”

2. Insert switch’s piggyback plug into outlet.

3. Plug pump into piggyback plug.

4. Check installation. Allow system to cycle to ensure

proper operation.

Direct Wire Install

1. Follow steps 1 through 4 of “Mounting the Switch”

2. Further wiring of switch should be done by

qualified professionals only.

3. Check installation. Allow system to cycle to ensure

proper operation.

liquid-tight

connector

230V

pump

230V

power

source

junction

box

black

white

L1

L2

G

G

L1

L2

G

230 VAC

In 230 VAC pump installations, one side of

the line going to the pump is always HOT.

This condition exists if the switch is on or

off. Install double pole disconnect on all

230 VAC pump circuits.

n WARNING