4

Ground motor before con-

necting to electrical power

supply.

Failure to ground motor

can cause severe or fatal

electrical shock hazard.

Do not ground to a gas

supply line.

To avoid dangerous or

fatal electrical shock, turn

OFF power to motor before

working on electrical connec-

tions.

Supply voltage must be

within ±10% of nameplate

voltage. Incorrect voltage can

cause fire or seriously damage

motor and voids warranty. If in

doubt consult a licensed electri-

cian.

Use wire size specified in

Wiring Chart (below). If

possible, connect pump to a separate branch circuit with no

other appliances on it.

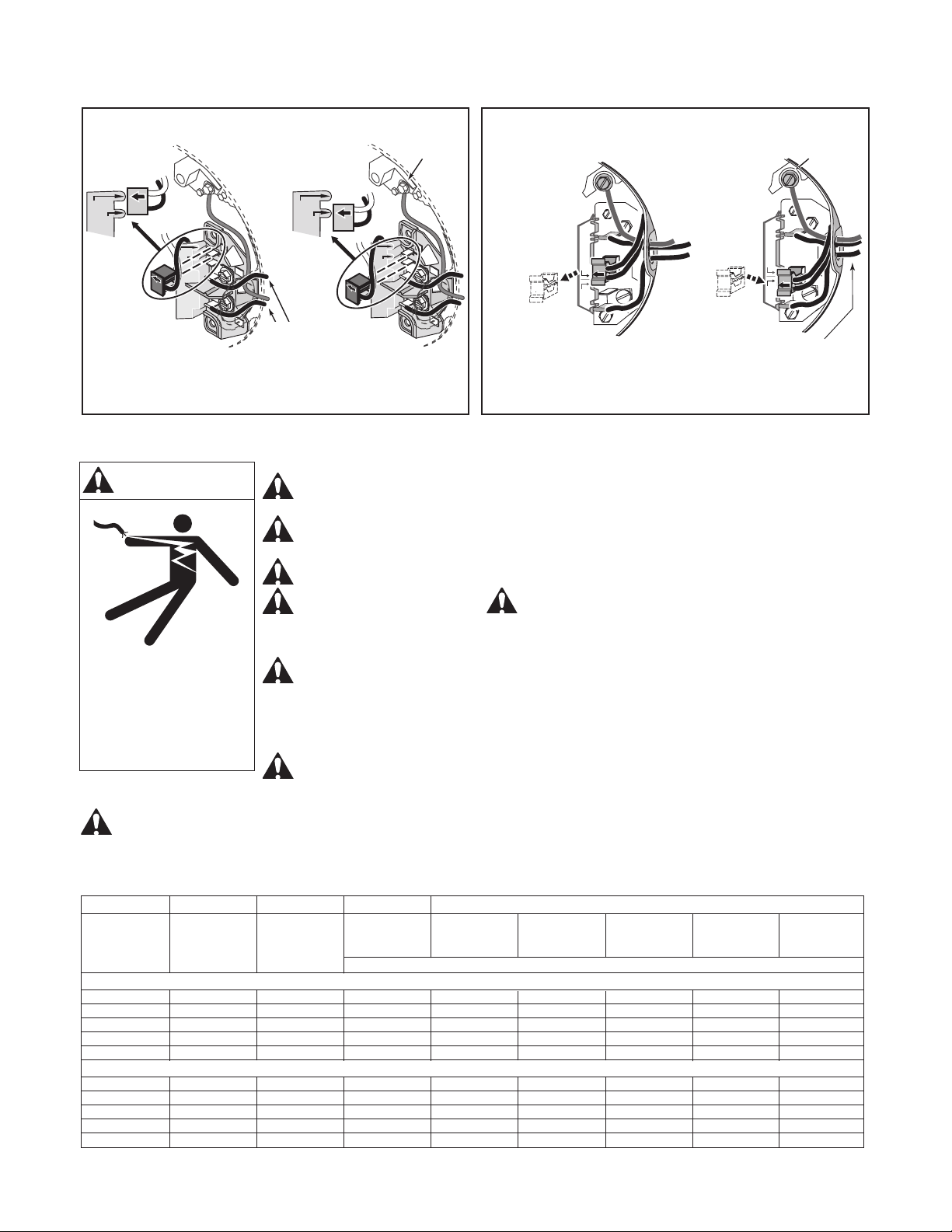

Wire motor according to diagram on motor nameplate. If

nameplate diagram differs from diagrams below, follow

nameplate diagram.

WIRING

1. Install, ground, wire and maintain this pump in accordance

with your local electrical code and all other codes and ordi-

nances that apply. Consult your local building inspector for

local code information.

2. Ground the pump permanently using a wire of size and

type specified by local or National Electrical Code.

Do not ground to gas supply line.

3. Connect ground wire first. Connect to ground first, then to

green grounding terminal provided under motor canopy

(see Figure 3) identified as GRD. Make ground connection

to this terminal. Do not connect motor to electrical power

supply until unit is permanently grounded; otherwise seri-

ous or fatal electrical shock hazard may be caused.

4. For best ground connection, connect to a grounded lead in

the service panel or to a metal underground water pipe or

well casing at least 10 ft. long. If plastic pipe or insulated

fittings are used, run ground wire directly to the metal well

casing or use ground electrode furnished by the power

company.

WARNING

Hazardous voltage.

Can shock, burn, or

cause death.

Ground pump before

connecting to power

supply.

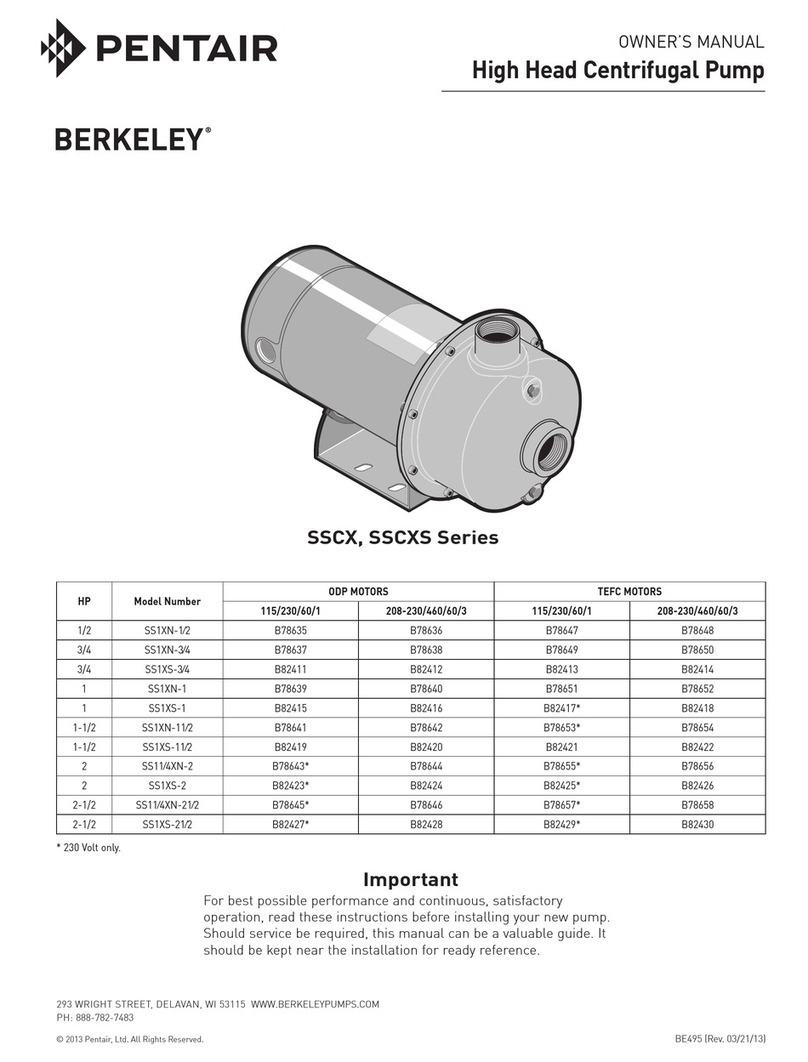

TABLE II - RECOMMENDED FUSING AND WIRING DATA - 60 CYCLE MOTORS

DIAMETER IN FEET FROM MOTOR TO METER

BRANCH 0’ 51’ 101’ 201’ 301’ 401’

MOTOR MAX. LOAD FUSE* TO TO TO TO TO TO

HP AMPERES RATING 50’ 100’ 200’ 300’ 400’ 500’

AMPS WIRE SIZE

SINGLE PHASE - 115 VOLT

1/3 9.4 15 14 14 12 10 8 8

1/2 9.4 15 14 14 12 10 8 8

3/4 12.2 20 12 12 10 8 6 4

1 14.8 20 12 12 8 6 6 4

1-1/2 19.2 30 10 10 8 6 4 2

SINGLE PHASE - 230 VOLT

1/3 4.7 15 14 14 14 14 14 12

1/2 4.7 15 14 14 14 14 14 12

3/4 6.1 15 14 14 14 14 12 10

1 7.4 15 14 14 14 12 12 10

1-1/2 9.6 15 14 14 14 12 10 10

*A Fusetron is recommended instead of a fuse in any motor circuit

3914 0301

115 V

230 V

230 Volt to 115 Volt Conversion. Move plug to change voltage.

A

L1

230

Volts

115

Volts

230 Volt to 115 Volt Conversion. Move plug to change voltage.

Pull plug

straight

out from

terminal

board;

1.

1.

2.

2.

Plug in again

with arrow

on plug

pointing to

'115 Volts'.

Ground

Screw

A

L1

230

Volts

115

Volts

Clamp the power cable to prevent

strain on the terminals.

Ground

Screw

Clamp the power cable to prevent

strain on the terminals.

Connect the green (or bare copper)

ground wire to the grounding screw.

Connect the green (or bare copper) ground

wire to the green ground screw.

230V

115V

230V

115V

A

A

L2

L2

L1

L1

230V

115V

A

A

L2

L2

L1

L1

230V

115V

Power Supply

Wires

Figure 3 – Wiring Connection Diagram.

ELECTRICAL

Motor Terminal Block Wiring (as viewed from rear of motor, canopy removed)