2

Plumbing Installation

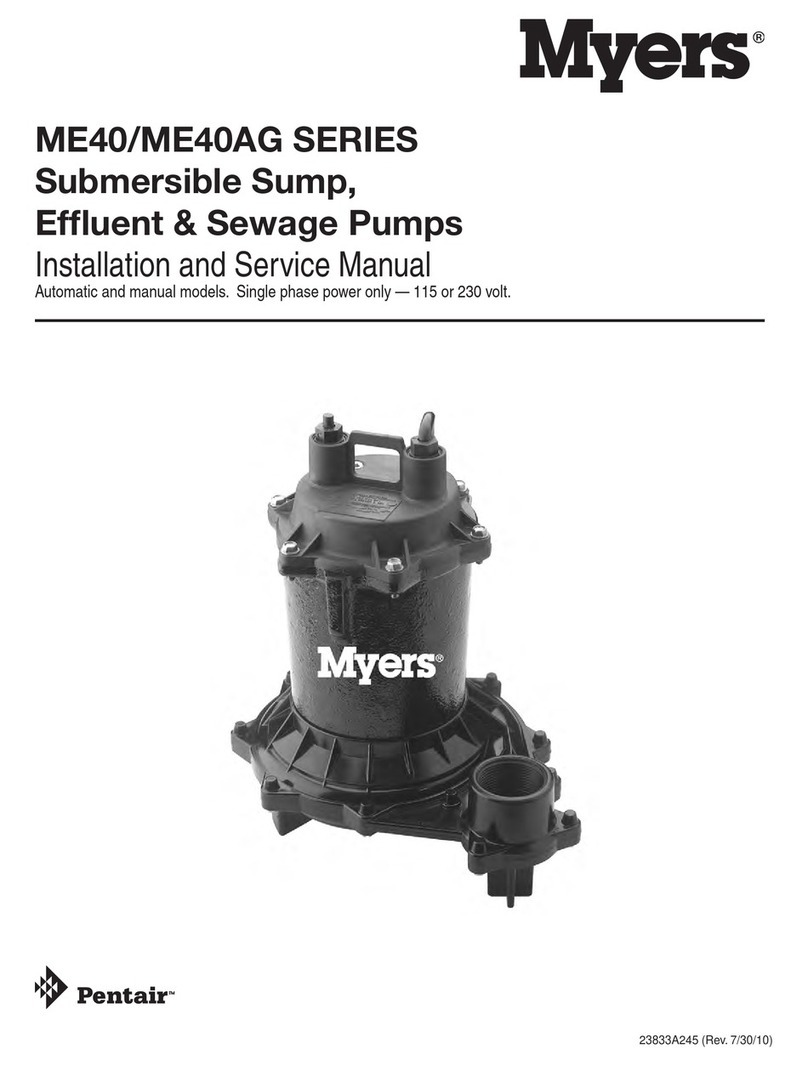

Hazardous Suction Can trap persons against

suction inlet.

Always use strainer on suction hose to prevent

entrapment.

IMPORTANT

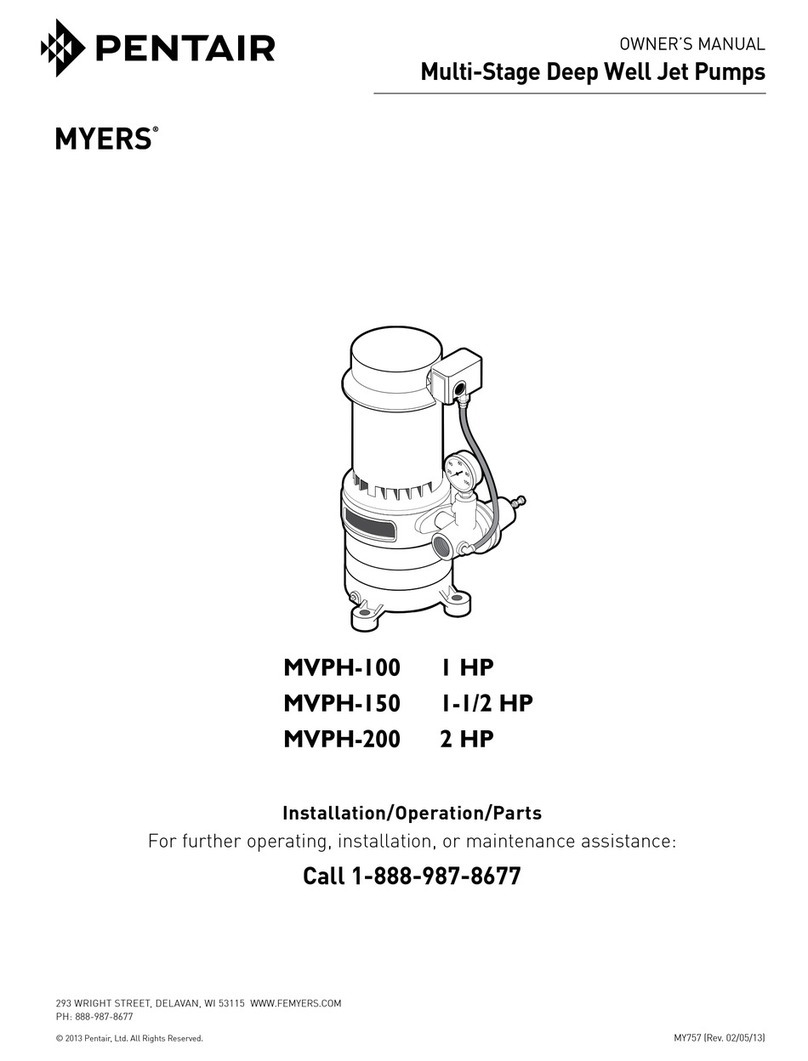

For best possible performance and continuous, sat-

isfactory operation, read these instructions before

installing your new pump. Should service be required,

this manual can be a valuable guide. It should be kept

near the installation for ready reference.

Preliminary to Mounting

Before setting up the pump for operation, check to

see that the motor and pump turn freely by hand. If it

cannot be turned over by pulling on the recoil starter,

open casing to check for obstructions lodged in pump.

Basket Strainer

A basket strainer is to be used when transferring solutions

that may contain debris and solids which could become

lodged in the pump or damage the impeller. Because of the

high flow capacity of this pump, unknown debris could be

siphoned off the bottom of the tank. Install the strainer on the

suction side of the pump whenever possible to avoid pump

damage.

INSTALLATION

LOCATION

Place unit as close to water source as possible to minimize

suction lift, obtain the best pumping performance, and

aid in priming.

For permanent installation, mount unit on a foundation that

will support the weight of the pump and engine and also

provide stability while the pump is running. For most per-

manent installations, it is advisable to bolt unit directly to

foundation.

NOTICE: Settling and/or shifting during operation can

cause piping to place excessive strain on the pump and

may damage pump case. Set pump on hard level surface.

Non-level surfaces may cause the oil sensor in the engine

to shut down the unit.

SUCTION CONNECTION

Connect either rigid pipe or flexible suction hose to pump

suction. If hose is selected, hose must be rated to hold the

suction vacuum and prevent collapse while the pump is

running.

Make the suction line a continuous rise from the water

source to the pump. High spots can trap air and also make

priming difficult. Make sure all connections are tight and

free of air leaks.

NOTICE: Suction pipe or hose must be at least as large

as the pump suction inlet in order for the pump to operate

properly. If the inlet line is longer than approximately 6 feet,

use the next size larger line.

Minimum depth for the suction inlet is determined by the

diameter of the suction line.

DISCHARGE CONNECTIONS

Your pump is equipped with a single port discharge. Select

the appropriate size for the application. Install a “T” to

allow easy priming of the pump without disconnecting the

piping, or by using the priming plug on the housing.

WARNING: Do not pump flammable or explosive fluids

such as Gasoline, Fuel Oil, Kerosene, etc. Do not use

in explosive atmospheres. The pump should be used

only with liquids that are compatible with the pump

component materials. Failure to follow this Warning

can result in Personal Injury and/or Property Damage

and Will Void the Product Warranty.

1. DO NOT EXCEED recommended speed, pressure and

temperature (120 degrees F) for pump and equipment

being used.

2. BEFORE SERVICING, drain all liquids from the system

and flush. Remove the spark plug wire from the spark

plug before servicing the pump or engine.

3. Secure the discharge lines before starting the pump.

An unsecured line may whip, causing personal injury

and/or property damage.

4. Check hose for weak or worn condition before each

use. Make certain that all connections are tight and

secure.

5. Periodically inspect the pump and the system

components. Perform routine maintenance as required

(see Maintenance section).

6. Protect pump from freezing conditions by draining

liquid and pumping a permanent-type automobile

antifreeze containing a rust inhibitor through the

system, coating the pump interior. A 50% mixture with

water is recommended.

7. Do not operate a gasoline engine in an enclosed area.

Be sure the area is well ventilated.

WARNING: Gasoline is a highly combustible fuel. The

improper use, handling, or storage of Gasoline can be

dangerous. Never touch or fill a hot engine.

8. Use only pipe, hose and fittings rated for the maximum

psi rating of the pump.

9. Do not use these pumps for pumping water or other

liquids for human or animal consumption.

Warning