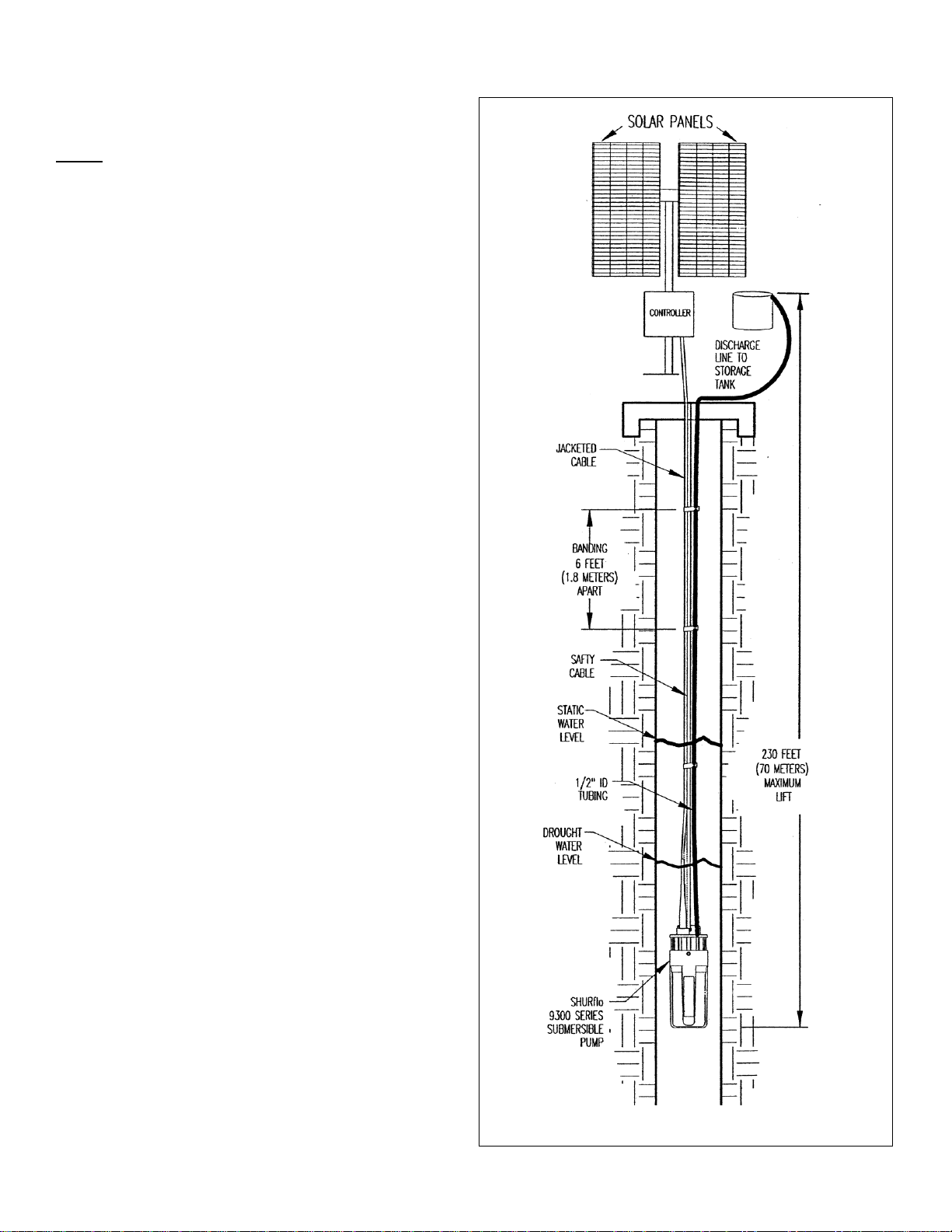

Pentair SHURflo 9325 Series User manual

Other Pentair Water Pump manuals

Pentair

Pentair ONGA FARMMASTER JJ Series User manual

Pentair

Pentair FP4000 Series User manual

Pentair

Pentair STA-RITE DS3 Series User manual

Pentair

Pentair SHURFLO User manual

Pentair

Pentair AURORA 1070 Series Operating instructions

Pentair

Pentair PENTEK DEFENDER CSC-LINK User manual

Pentair

Pentair Hydromatic SP50 User manual

Pentair

Pentair Keystone GR Series User manual

Pentair

Pentair Fairbanks Nijhuis 1590F Operating instructions

Pentair

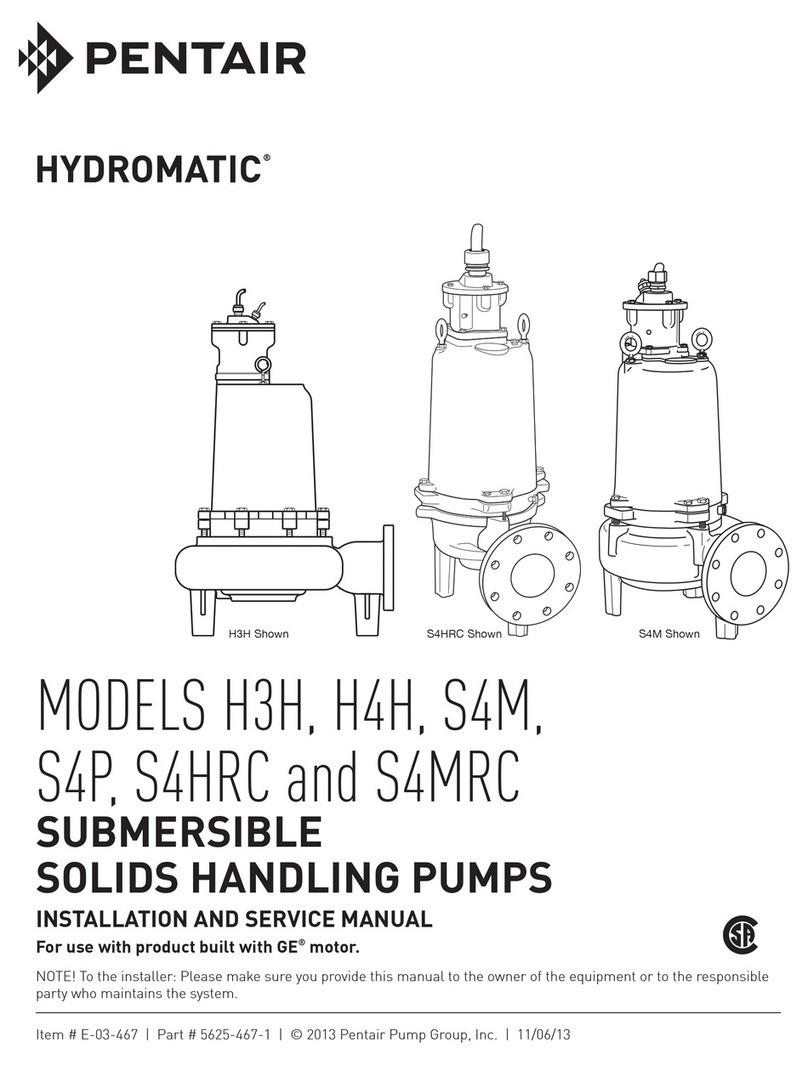

Pentair HYDROMATIC H3H Manual

Pentair

Pentair Berkeley 10VT Series User manual

Pentair

Pentair Fairbanks Nijhuis 7100 19A User manual

Pentair

Pentair STA-RITE SE370 User manual

Pentair

Pentair MYERS CT Series User manual

Pentair

Pentair MYERS DP Series Manual

Pentair

Pentair Berkeley 5SLJ User manual

Pentair

Pentair Fairbanks nijhuis 2800 Installation and operating instructions

Pentair

Pentair Myers VH30 Manual

Pentair

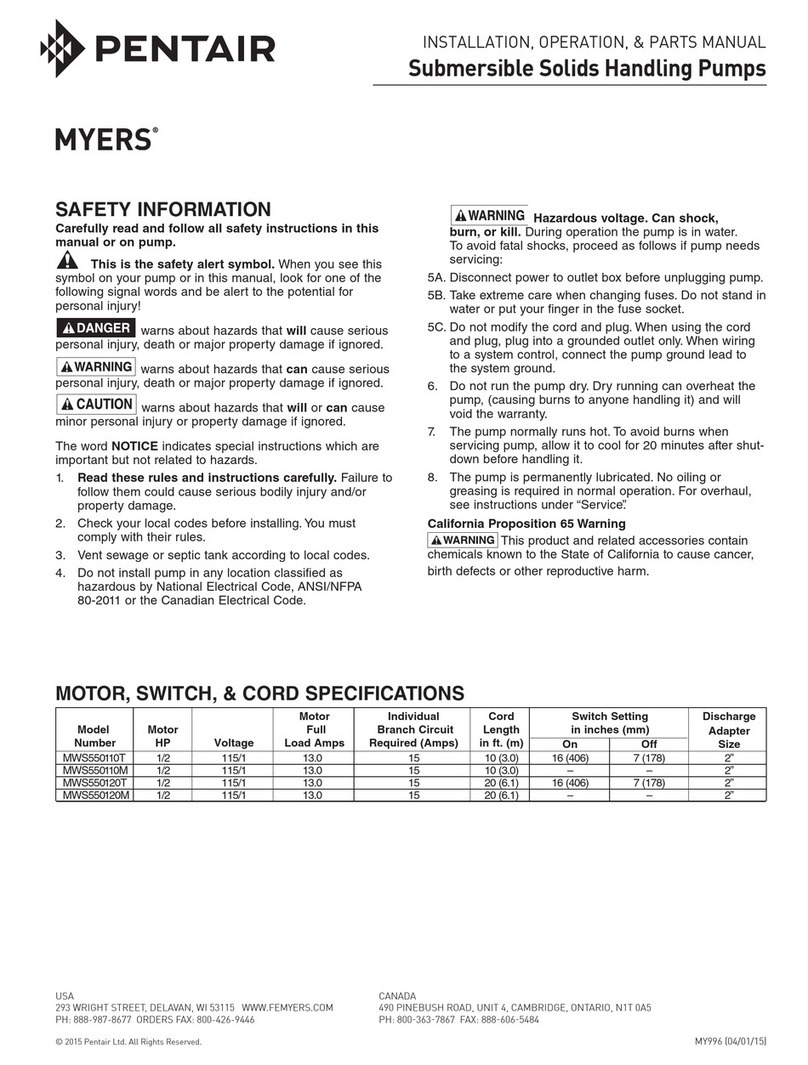

Pentair MYERS MWS550110T Guide

Pentair

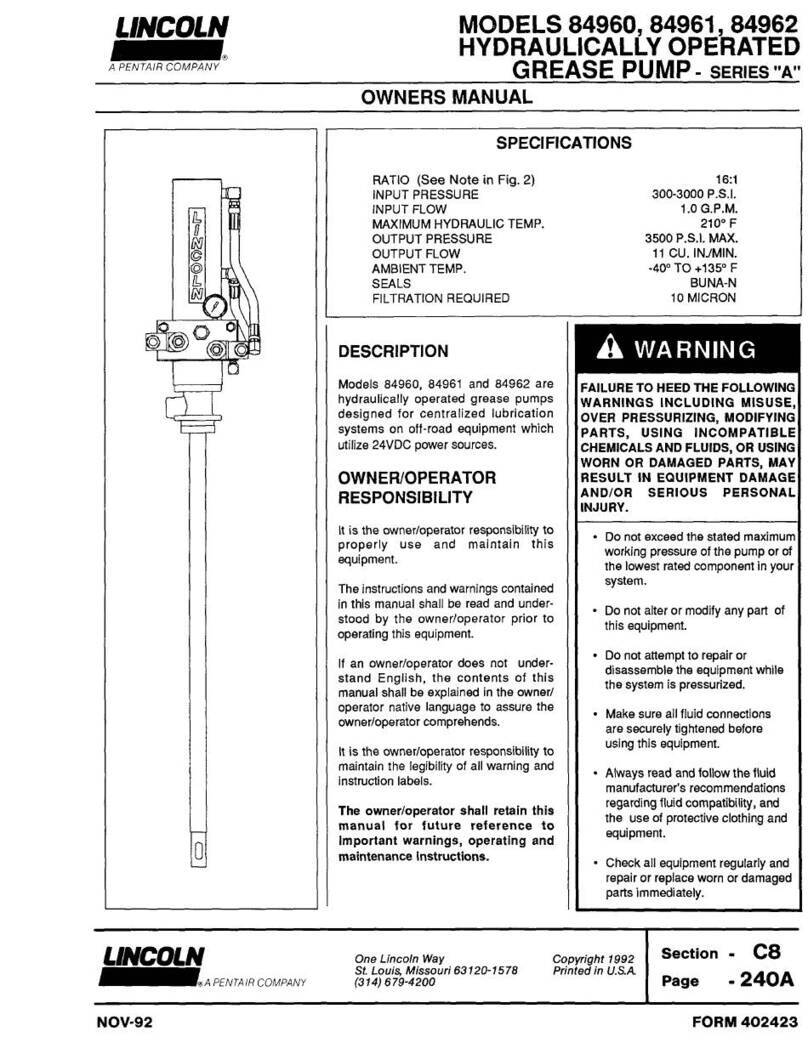

Pentair LINCOLN 84960 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual