50 2 M6

65 2½ M8

80 3 M8

100 4 M8

125 5 M10

150 6 M10

200 8 M10

250 10 M12

300 12 M12

Pentair reserves the right to change the contents without notice page 5

Copyright © 2012 Pentair Valves & Controls. All rights reserved.

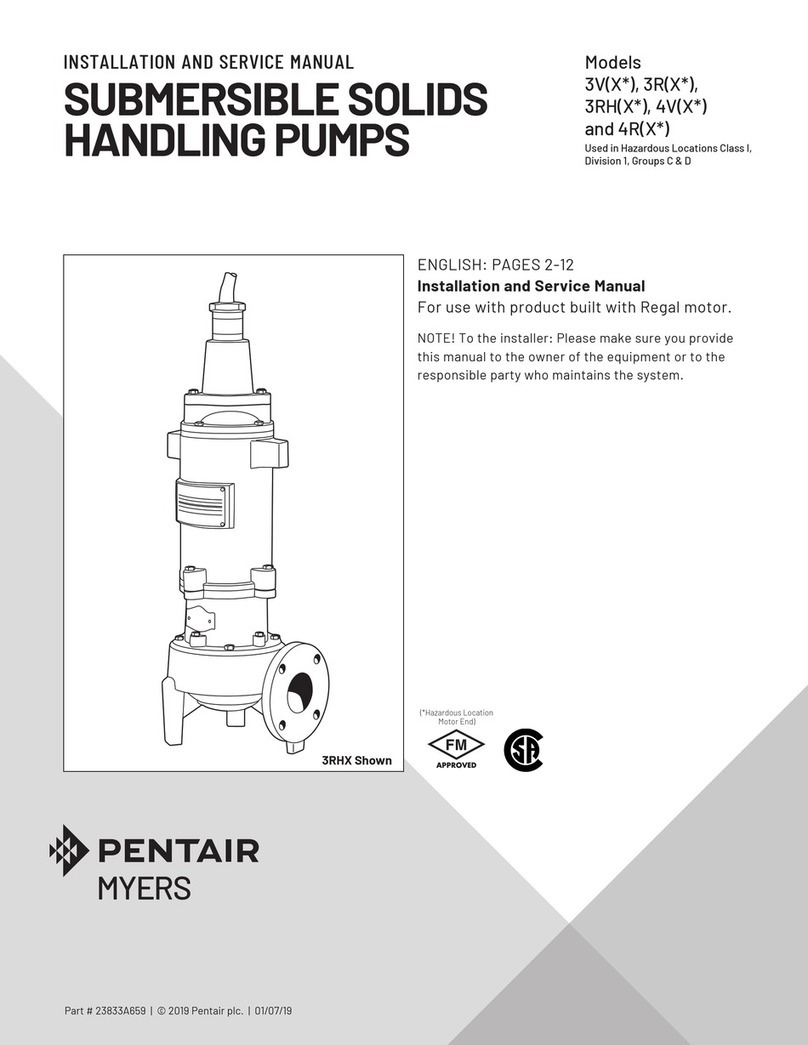

Keystone

Series GR Resilient Seated Butterfly valves

GRW/GRL Installation & Operation Manual

4 Maintenance for Series GRW/GRL resilient seated butterfly valves

Sizes NPS 2-12 (DN 50-300)

WARNING!

Depressurize and, if necessary in case of dangerous fluids, drain the line and flush with appropriate

cleaning fluid before starting any maintenance. Failure to do so may cause serious personal injury

and/or equipment damage.

Before disassembling the valve, ensure the valve has been decontaminated correctly from any

harmful gasses or liquids and that it is within a safe temperature range for handling.

Personnel making any adjustments to the valves should utilize suitable equipment. All required

personal protection means should be worn.

We recommend that personnel should be trained in all aspects of these instructions before carrying

out handling of any valve.

4.1 Routine maintenance

The Keystone Series GRW/GRL butterfly valves are designed to require a minimum of

maintenance.

Routine maintenance or lubrication is not required, we recommend periodic (visual) inspection to

ensure satisfactory operation and sealing to the environment.

4.2 Removing the valve from the pipe system

1. Turn the disc to nearly closed position. (The disc is in line with the parallel flats in the shaft).

2.Loosen all flange bolts and remove the bolts, which prevent removing of the valve.

3.Spread the flanges with adequate tooling, and remove the valve.

4.3 Valve disassembly (see Figure 3)

1. Turn the disc to almost open position.

2. Remove actuator.

3. Remove the circlip from the top of the body.

4. Pull the upper shaft out of the body.

5. Remove the bushing, shaft seal and circlip from the shaft.

6. Unscrew and remove the plug from the bottom of the body.

7. Pull the lower shaft out of the body (a threaded hole is provided in the end of the shaft). (See

Table 1 for tapped hole dimensions)

8. Remove the disc by pulling or ‘rolling’ out of the seat bore.

9. Remove the seat from the body: pry under both seat edges at one point, collapse the seat into

the shape of a round bottom heart configuration and pull the seat out of the body bore.

10.Remove bearings from shaft bores.

4.4 Valve assembly (see Figure 3)

1. Clean all parts. Use silicone grease on the disc to facilitate the assembly.

2. Mount the two shaft bearings close to the bore of the body.

3. If removed before, re-assemble the packing in the body.

4.

Collapse the seat in the shape of a round bottom heart and firmly place the ‘bottom’ part of the seat

into position in the body. Align the holes in the seat properly with the holes in the body.

5. Fit the circlip to the groove in the upper shaft.

6. Insert the upper shaft with sufficient (silicone) grease so that it protrudes approximately 3/8”

(10 mm) into the inside bore of the seat. Insert the lower shaft with sufficient (silicone) grease

so that it is flush with the inside bore of the seat. Install the disc, with the hexagonal bore to

the top. Insert the disc in the seat with the shaft bore on the topside against the shaft, leaving

the bottom part of the disc just outside the seat. Ensure the keyway or parallel flats on

shaft are aligned to the disc edge. Push the bottom part of the disc in place with a twisting

motion.

7. Insert the shafts completely using a rotating pressure on the shaft, and a rotating motion on

the disc. Pay special attention in order that the seat is not damaged due to any misalignment

of stem holes.

3.6 Troubleshooting guide

Symptom Possible cause Resolution

Valve would not rotate Actuator has failed Replace or repair

Valve packed with debris Flush or clean valve to remove debris

Valve leaking Valve not fully closed Close valve, check actuator stop settings

Debris trapped in valve Cycle and flush (with valve open) to remove debris

Seat is damaged Replace seat

Jerky operation Extreme dry application Put some silicone oil on seat or increase size of actuator

Air supply actuator inadequate Increase air supply pressure and/or volume

Table 1 -

Bottom shaft tapped hole dimensions

Valve size Hole dimension

(DN) (NPS)

8. Put some sealant on the plug and screw

it into the lower shaft bore.

9. Fit the bushing over the top of the shaft

and into the top of the body. Retain it in

place with the circlip.

10.Mount the actuation.

4.5 Re-installing the valve

See section 3.3.1