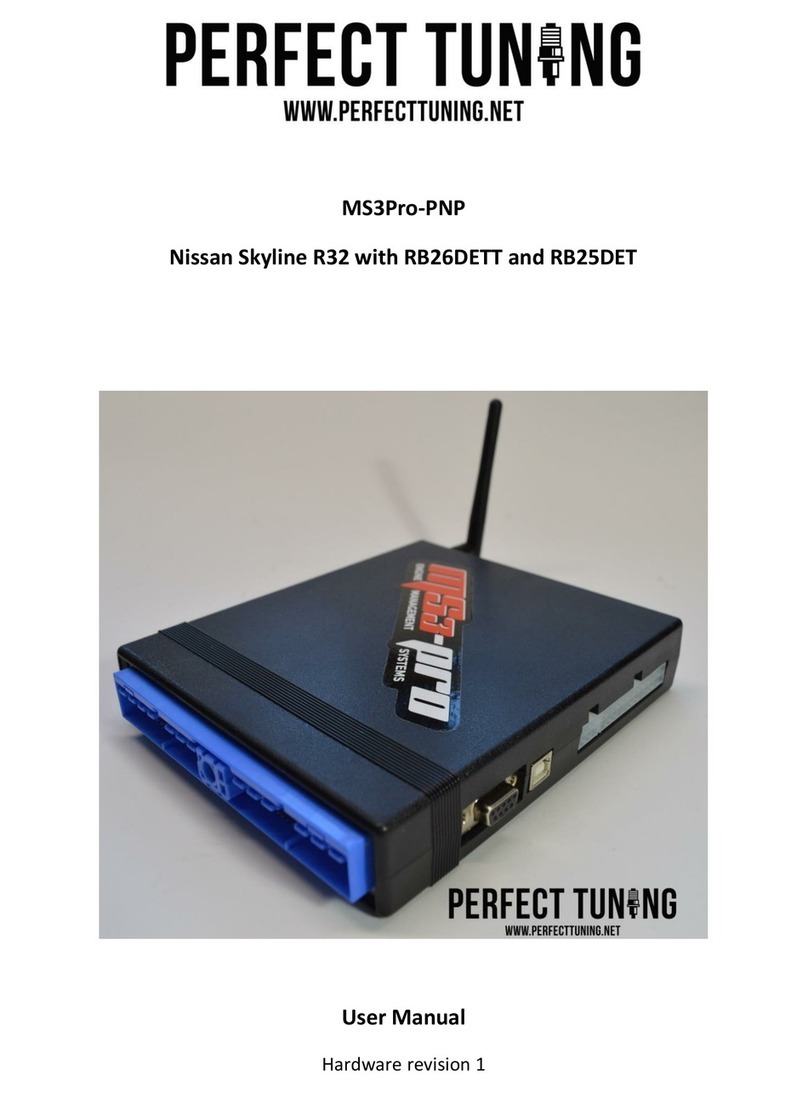

www.PerfectTuning.net 2 November 2017

Table of content

Table of content............................................................................................................................................2

Warning.....................................................................................................................................................4

Introduction ..............................................................................................................................................4

1 Wiring....................................................................................................................................................5

1.1 Connection to the Link G4+ or Vi-PEC...........................................................................................5

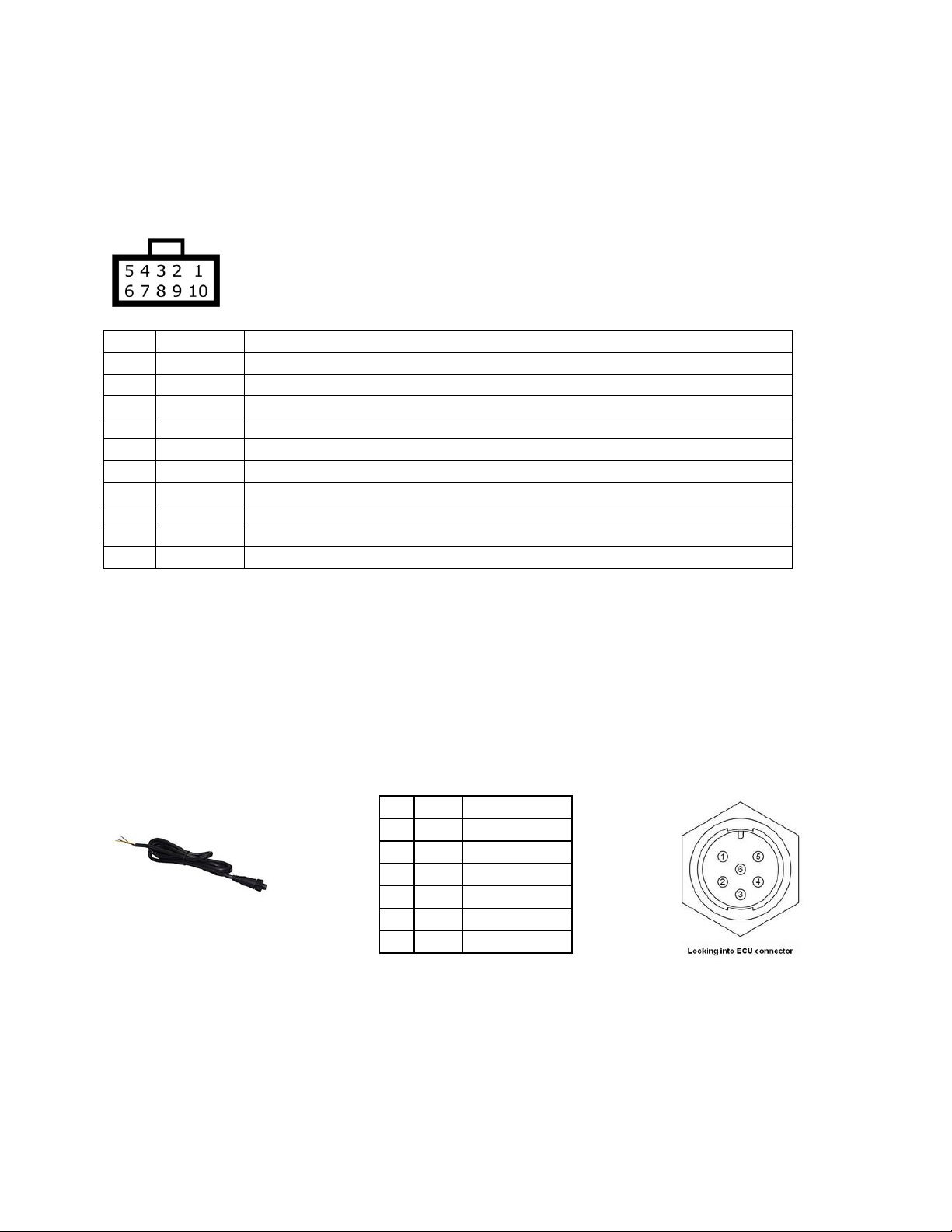

1.1.1 Atom Header pinout: ............................................................................................................6

1.1.2 Monsoon Header Pinout:......................................................................................................6

1.1.3 Kurofune Header Pinout .......................................................................................................6

2 Menus and buttons...............................................................................................................................7

2.1 Real-Time Display Screens ............................................................................................................7

2.2 Settings..........................................................................................................................................7

2.2.1 Screen Brightness..................................................................................................................7

2.2.2 LED Brightness.......................................................................................................................7

2.2.3 Units......................................................................................................................................7

2.2.4 Input Configuration...............................................................................................................7

2.2.5 Wi-Fi hotspot.........................................................................................................................7

2.2.6 Safe Mode.............................................................................................................................8

2.2.7 Edit text color........................................................................................................................8

2.2.8 Disable / Enable screen designer..........................................................................................8

2.2.9 Select boot mode..................................................................................................................8

2.2.10 Select ECU Model..................................................................................................................8

2.2.11 General Info ..........................................................................................................................8

2.2.12 Factory Reset.........................................................................................................................8

3 CAN Bus.................................................................................................................................................9

3.1 CAN bus resistor............................................................................................................................9

3.2 Display values from ECU over CAN bus.........................................................................................9

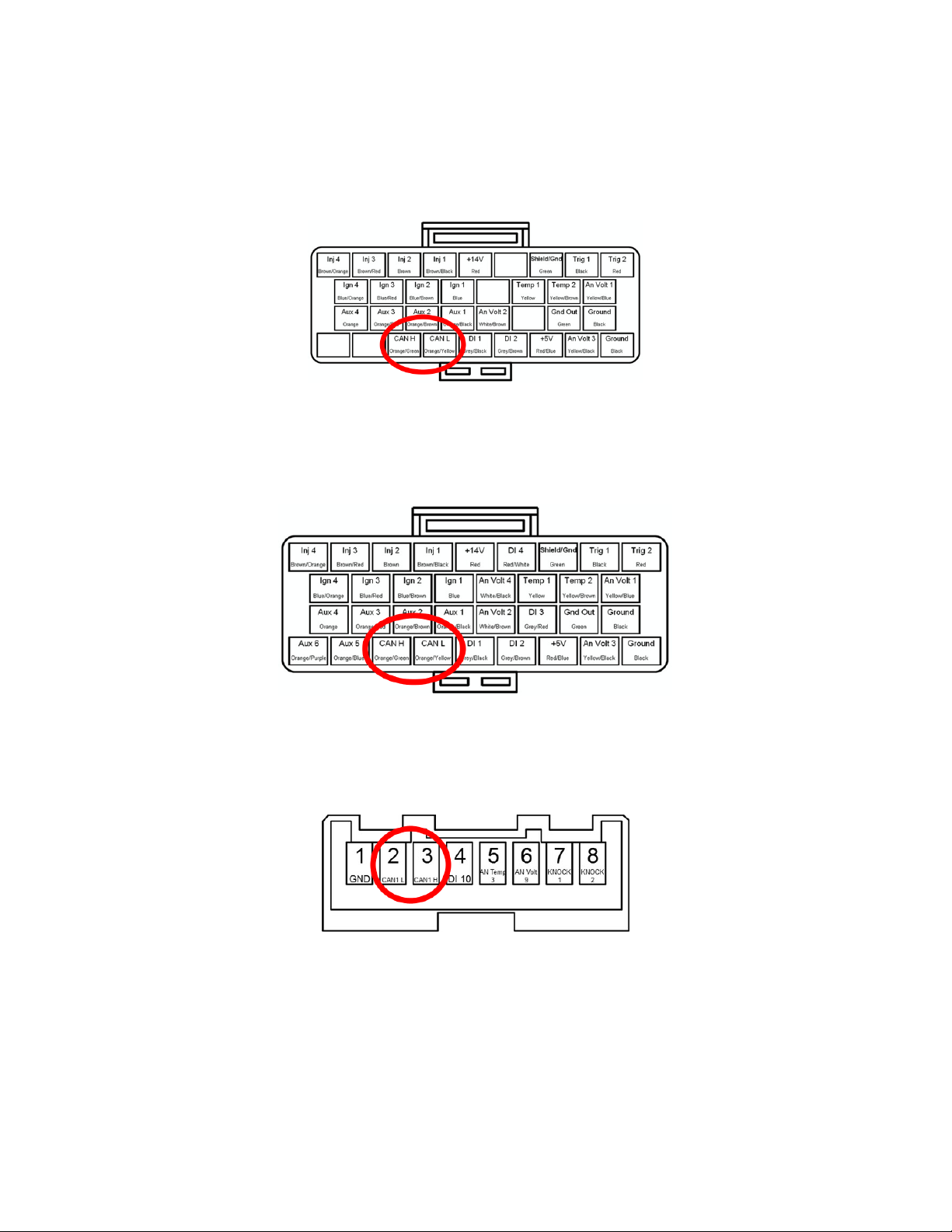

3.2.1 Link G4+ and Vi-PEC i44 or i88 ECU configuration..............................................................10

3.2.2 With Link G4 or Vi-PEC v44, v88..........................................................................................10

3.2.3 Custom values with Link G4 (requires gauge firmware version 60 and up). ......................11

4 WiFi .....................................................................................................................................................13

4.1 How to connect and access the gauge configuration webpage .................................................13