SPECIFICATIONS

Specifications are

subject to change

without notice

IMPORTANT SAFETY INFORMATION

IMPORTANT SAFETY INFORMATION

WARNING!

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS AND

WARNINGS BEFORE OPERATING THIS TOOL. FAILURE TO DO

SO MAY RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE AND WILL VOID WARRANTY.

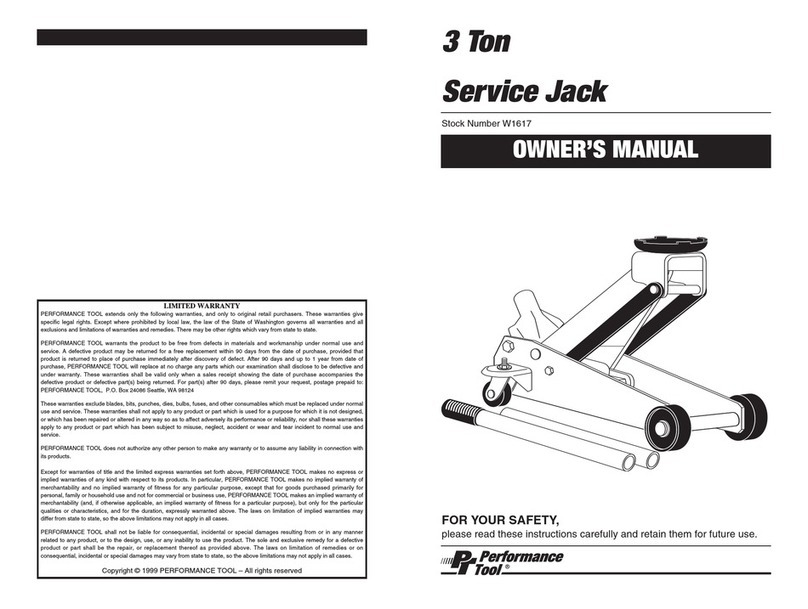

Specifications:

Capacity: ................................4000 lbs.

Low Lift Height: .......................2 3/4 in.

Max. Lift Height:...........................20 in.

Overall Dimensions:

Length: ...................................26 1/2 In.

Width: .....................................13 1/2 In.

Height:............................................9 In.

........................................50 3/8 with bar

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp

or wet locations. Don’t expose to rain. Keep work area well lighted. Do not

use electrically powered tools in the presence of flammable gases or liquids.

Do not bring combustible materials near the tools.

3. Keep children away. Children must never be allowed in the work area. Do not

let them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location

to inhibit rust. Always lock up tools and keep out of reach of children and other

untrained persons. Switch off all unused electrical tools when stored. Tools

are dangerous in the hands of untrained users.

5. This is a lifting device only. Do not move load while it is on the jack. Load

must be supported immediately by Jack Stands or other appropriate means.

6. Do not overload jack beyond rated capacity. Overloading can cause damage

to or failure of the jack.

7. REFER TO YOUR VEHICLE OWNERS MANUAL FOR PROPER JACKING

PROCEDURES. Lift only on areas of the vehicle as specified by the vehicle

manufacturer.

8. Work Safe. Keep proper footing and balance at all times. Do not reach over or

across running machines, hoses, etc.

9. This jack is designed for use only on hard level surfaces capable of sustain-

ing the load. Use of jack on other than hard level surfaces can result in jack

instability and possible loss of load.

10.Stay alert. Watch what you are doing, us common sense. Be sure all

personnel are clear of load before lowering load. Ensure that no personnel

pass underneath load until load is securely supported by jack stands Do not

operate any tool when you are tired.

11.Take care of your jack. Keep the jack clean for better and safer work. Follow

the maintenance instructions and the notices. Regularly inspect all parts.

Repairs should only be carried out by a qualified technician. Use only original

PERFORMANCE TOOL® replacement parts.

12.Check for damaged parts. Before using any tool, any part that appears dam-

aged should be carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment and binding of moving

parts; any broken parts or mounting fixtures; and any other condition that may

affect proper operation.Any part that is damaged should be properly repaired

or replaced by a qualified technician.

13.Repairs should only be carried out by a qualified electrician using original

PERFORMANCE TOOLS® replacement parts. Failure to do so can lead to

accidents for the operator. Use of any other parts will void the warranty. Only

use accessories intended for use with this tool. Approved accessories are

available from Performance Tool®.Use only accessories that are recommend-

ed by the manufacturer for your model. Accessories that may be suitable for

one tool may become hazardous when used on another tool.

14.Do not operate any tool if under the influence of alcohol or drugs. Read

warning labels on prescriptions to determine if your judgment or reflexes are

impaired while taking drugs. If there is any doubt, do not operate any tool.

15.Maintenance. For your safety, maintenance should be performed regularly by

a qualified technician.

WARNING: This product and its packaging contain a chemical known to the

State of California to cause cancer, birth defects, or other reproductive harm.

WARNING: The warnings, cautions, and instructions discussed in this instruc-

tion manual cannot cover all possible conditions and situations that may occur. It

must be understood by the operator that common sense and caution are factors

which cannot be built into this product, but must be supplied by the operator.

Read and understand all of the instructions provided in the instruction manual of

this product, as well as, any other tool (s) used with this product.