SAFETY GUIDELINES / DEFINITIONS

IMPORTANT SAFETY INFORMATION

WARNING

READ, UNDERSTAND AND FOLLOW ALL INSTRUCTIONS AND WARNINGS BEFORE OPERATING THIS

TOOL. FAILURE TO DO SO MAY RESULT IN PERSONAL INJURYAND/OR PROPERTY DAMAGE AND WILL

VOID WARRANTY.

1. Use personal protective equipment. Always wear

eye protection.

2. Keep your work area clean and well lit.

3. Dress properly. Do not wear loose clothing or

jewelry. Keep your hair, clothing and gloves away

from hot parts.

4. Only use safety equipment that has been approved

by an appropriate standards agency.

5. Do not overreach. Keep proper footing and balance

at all times.

6. Keep bystanders, children, and visitors away while

operating this product.

7. Stay alert. Watch what you are doing, and use

common sense when operating this product. Do not

use this product while tired or under the inuence of

drugs, alcohol or medication.

8. Do not operate power tools in explosive

atmospheres, such as in the presence of

ammable liquids, gases or dust.

9. Tool/equipment service must be performed only by

qualied repair personnel. Service or maintenance

performed by unqualied personnel could result in

a risk of injury.

10. Prevent unintentional starting. Ensure the Trigger

is in the off position before connecting to power

source, picking up or carrying the tool.

11. Maintain labels and nameplates on this product.

These carry important information. If unread-

able or missing, contact Performance Tool for a

replacement.

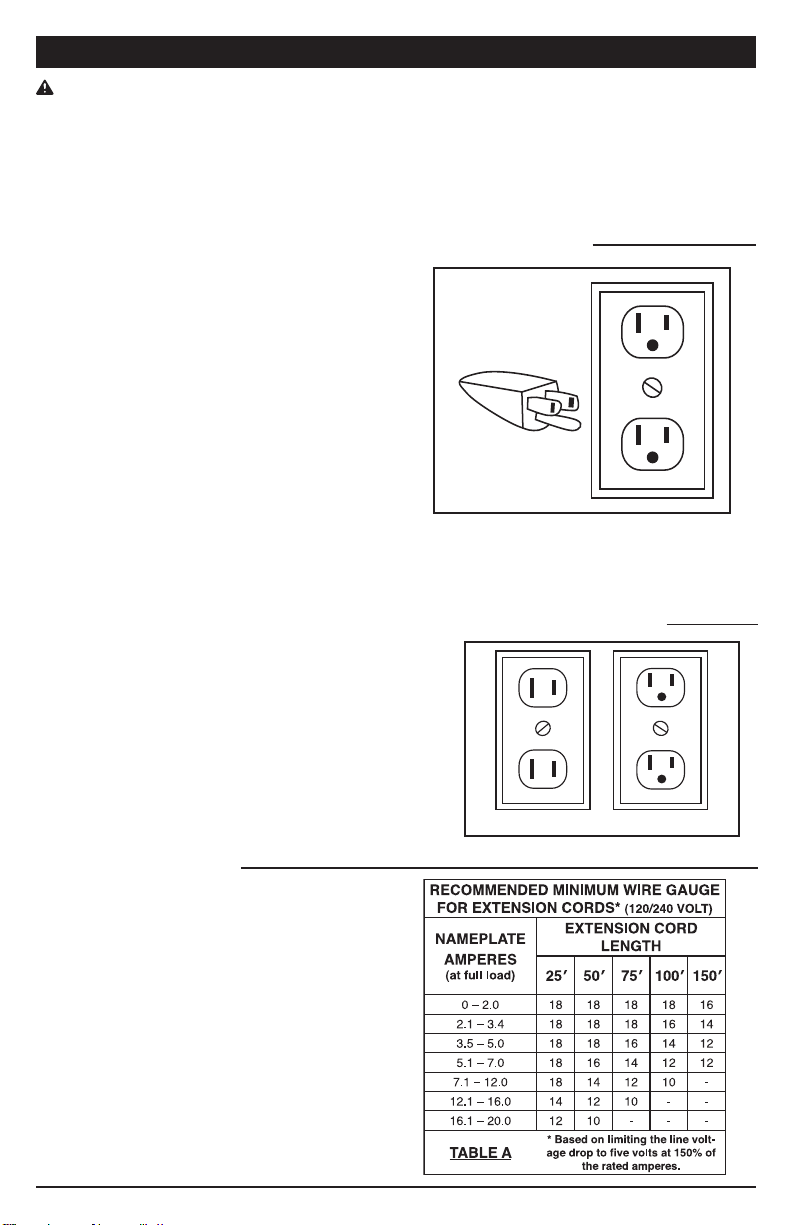

12. Power tool plugs must match the outlet. Never

modify the plug in any way.

13. Do not use any adapter plugs with grounded

power tools.

14. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts.

15. Do not expose power tools to rain or wet

conditions.

16. If operating a power tool in a damp location is

unavoidable, use a Ground Fault Circuit Interrupter

(GFCI) protected supply.

17. Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators.

18. The warnings, precautions, and instructions

discussed in this manual cannot cover all possible

conditions and situations that may occur. The

operator must understand that common sense and

caution are factors, which cannot be built into this

product, but must be supplied by the operator.

WARNING: This product and its packaging contain

a chemical known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING: Read and understand this entire instruction manual before attempting to assemble, install, operate or

maintain this product. Failure to comply with the instructions may result in serious personal injury

and/or property damage!

The following signal words are used to emphasize safety warnings that must be followed when using this product:

This instruction manual is intended for your benefit. Please read and follow the safety, installation, maintenance and troubleshooting steps

described within to ensure your safety and satisfaction. The contents of this instruction manual are based upon the latest product information

available at the time of publication. The manufacturer reserves the right to make product changes at any time without notice.

DANGER Indicates an imminently hazardous situation that, if

not avoided, WILL result in death or serious injury.

WARNING Indicates a potentially hazardous situation that, if

not avoided, COULD result in death or serious injury.

CAUTION Indicates a potentially hazardous situation that, if

not avoided, MAY result in minor or moderate injury.

NOTICE Indicates important information, which if not followed,

MAY cause damage to equipment.

2