Petsafe Simply Clean Operating and safety instructions

Other Petsafe Pet Care Product manuals

Petsafe

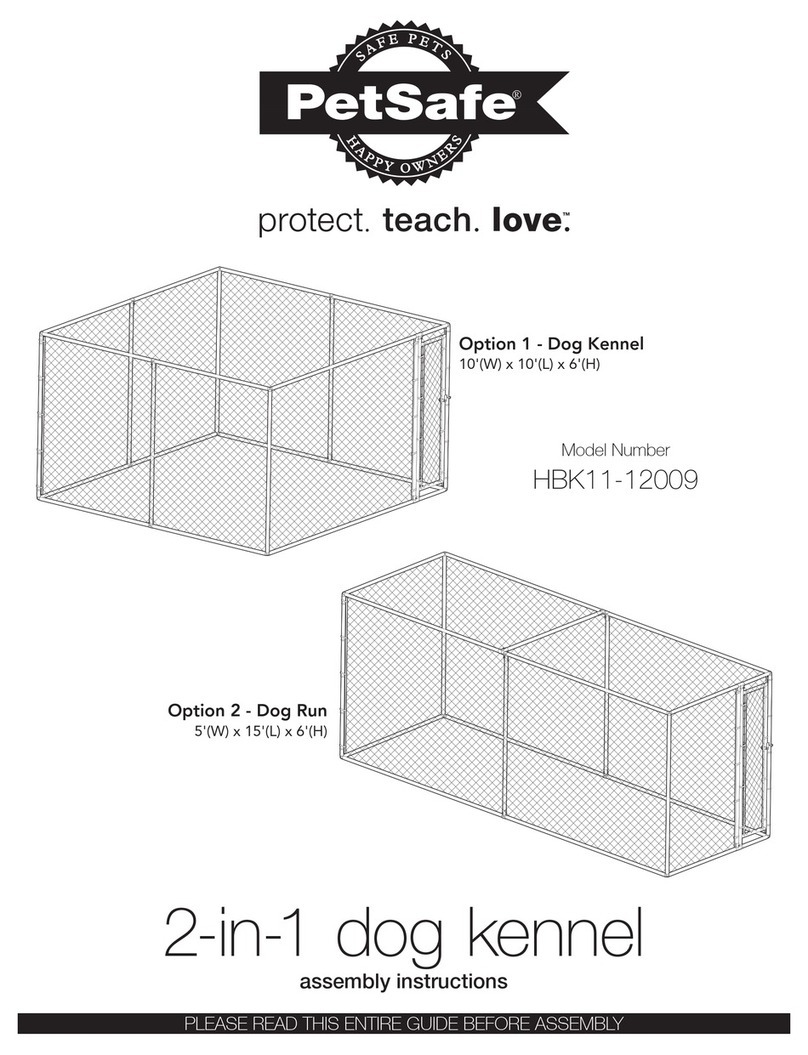

Petsafe HBK11-12009 User manual

Petsafe

Petsafe PDT20-11738 User manual

Petsafe

Petsafe In-Ground Fence System Add-A-Dog PIG19-11042 User manual

Petsafe

Petsafe Deluxe In-Ground Cat Fence User manual

Petsafe

Petsafe PIF00-12917 User manual

Petsafe

Petsafe Stay & Play PIF19-17106 User manual

Petsafe

Petsafe Staywel 300 series User manual

Petsafe

Petsafe Staywell 400 Series User manual

Petsafe

Petsafe In-Ground Cat Fence Setup guide

Petsafe

Petsafe PAC11-11037 User manual

Petsafe

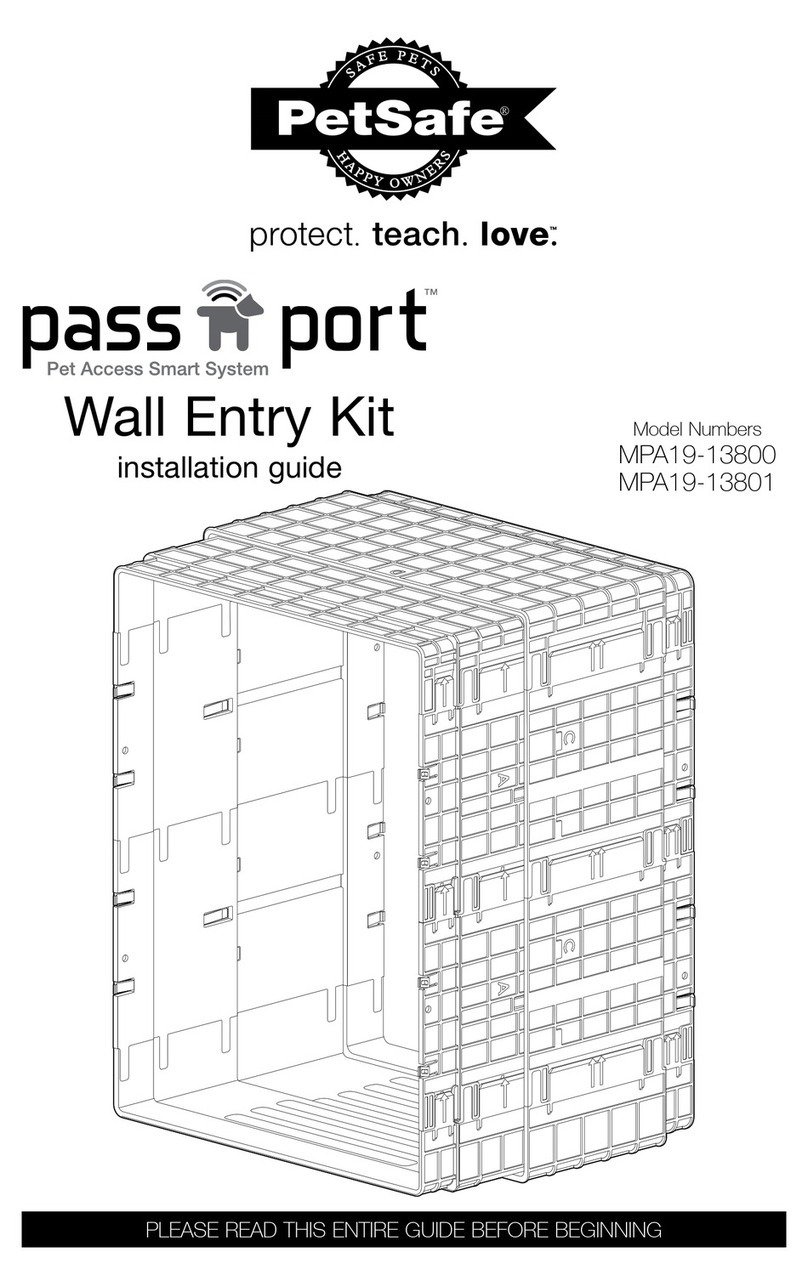

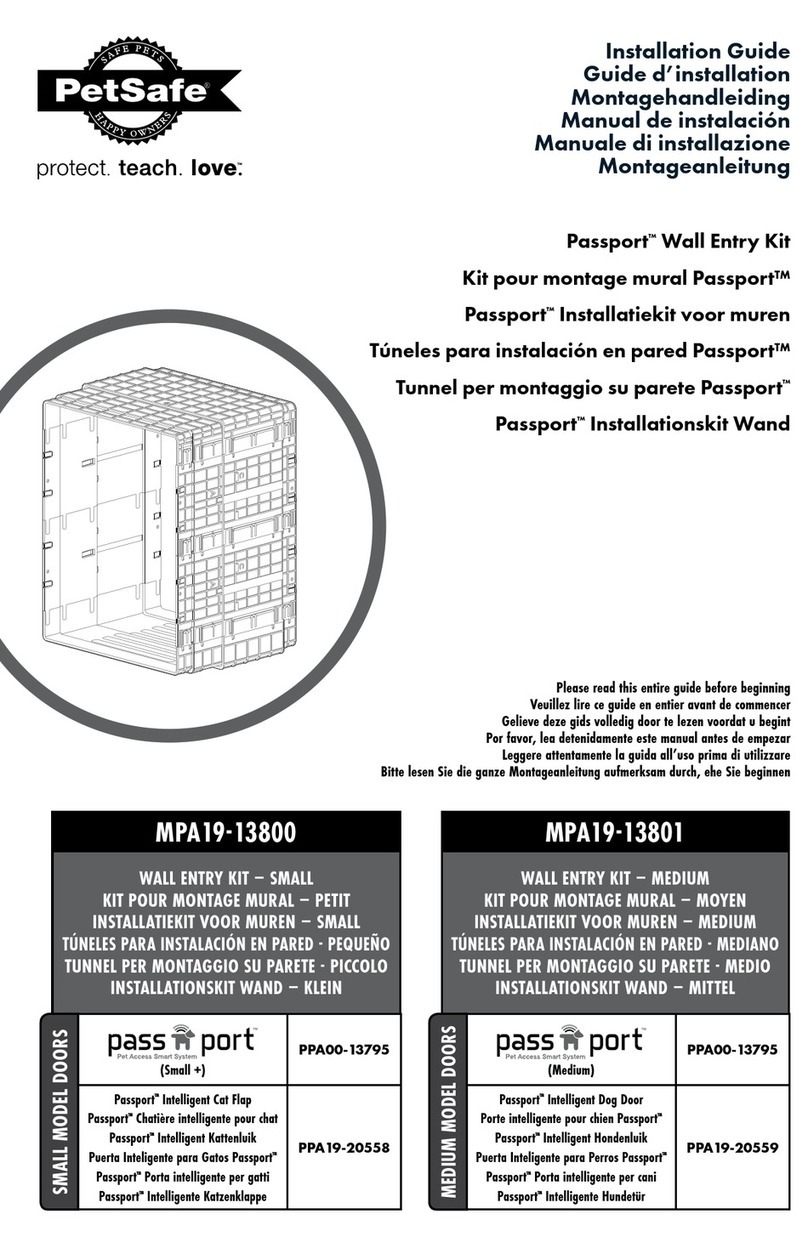

Petsafe Passport MPA19-13800 User manual

Petsafe

Petsafe Happy Ride GRP-PHRBS User manual

Petsafe

Petsafe HPA11-10888 User manual

Petsafe

Petsafe ULTRALIGHT SONIC BARK CONTROL User manual

Petsafe

Petsafe DrinkWell User manual

Petsafe

Petsafe Big Dog Spray Bark ControlCollar User manual

Petsafe

Petsafe PBC19-11796 User manual

Petsafe

Petsafe Drinkwell Mini Pet Fountain - 1.2 Litres User manual

Petsafe

Petsafe Cottageview Dog Kennel User manual

Petsafe

Petsafe ZND-1000 User manual

Popular Pet Care Product manuals by other brands

CADOCA

CADOCA Deuba 106911 instructions

Dogtra

Dogtra RR Deluxe owner's manual

Carson

Carson CONVERTIBLE PET YARD 2200 owner's manual

Creative Cedar Designs

Creative Cedar Designs K-9 Kabin Assembly instruction

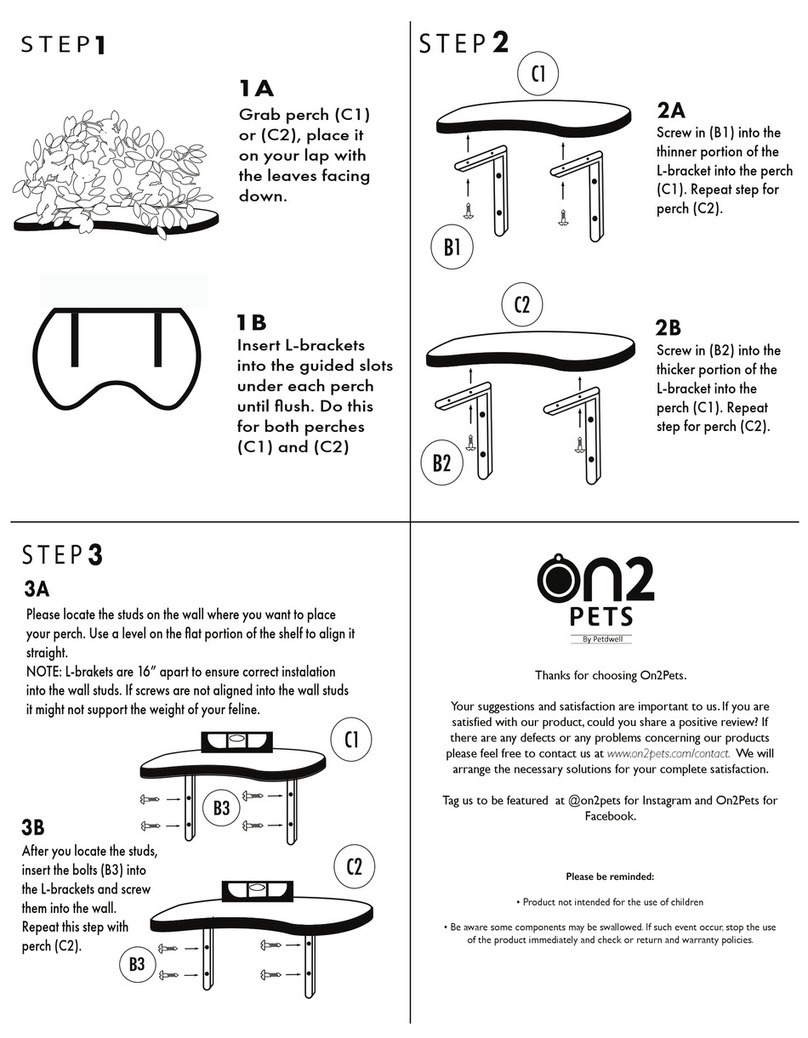

Petdwell

Petdwell ON2PETS Canopies Assembly instructions

UGO BASILE

UGO BASILE 7025 Series instruction manual