3

WARNINGS:

For your safety observe the following recommendations.

•This appliance contains a small quantity of R600a refrigerant which is environmentally friendly, but

flammable. It does not damage the ozone layer, nor does it increase the greenhouse effect.

•During transportation and installation, ensure that the tubing of the refrigerant circuit is not damaged.

•Avoid using or manipulating sharp objects near by the appliances.

•Leaking refrigerant can ignite and may damage the eyes.

•In the event any damage does occur, avoid exposure to open fires and any device which creates a

spark. Disconnect the appliance from the mains power.

•Thoroughly ventilate the room in which the appliance is located for several minutes.

•Notify Customer Service for necessary action and advice.

•The room for installing the appliance must be at least 1 cubic metre per 8 grams of refrigerant. The

refrigerant quantity contained in this appliance is listed above in grams; it is also noted on the Rating

Plate of the appliance.

•To avoid a hazard due to instability of the appliance, it must be fixed in accordance with the instructions.

•The symbol is a warning and indicates the refrigerant and insulation blowing gas are flammable.

•Risk of fire / flammable materials

•Do not store explosive substances such as aerosol cans with a flammable propellant in this appliance.

•When positioning the appliance, ensure the supply cord is not trapped or damaged.

•Do not locate multiple portable socket-outlets or portable power supplies at the rear of the appliance.

•The refrigerant and insulation blowing gas are flammable. When disposing of the appliance, do so only at

an authorized waste disposal centre. Do not expose to flame.

It is hazardous for anyone other than an Authorised Service Person to carry out

servicing or repairs to this appliance.

•Keep ventilation openings in the appliance enclosure or in the built-in structure clear of obstruction.

•Do not use mechanical devices or other means to accelerate the defrosting process, other than those

recommended by the manufacturer.

•Do not damage the refrigerant circuit.

•Do not use electrical appliances inside the food storage compartments of the appliance, unless they are

of the type recommended by the manufacturer.

•If you do not use the machine for a long time, please unplug the power plug from the socket or switch off

the power supply.

•This appliance is not intended for use by persons (including children) with reduced

Physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning use of the appliance by a person responsible

for their safety;

•Children should be supervised to ensure that they do not play with the appliance;

•Do not use extension cords or ungrounded (two prong) adapters;

•If the supply cord is damaged, it must be replaced by the manufacturer.

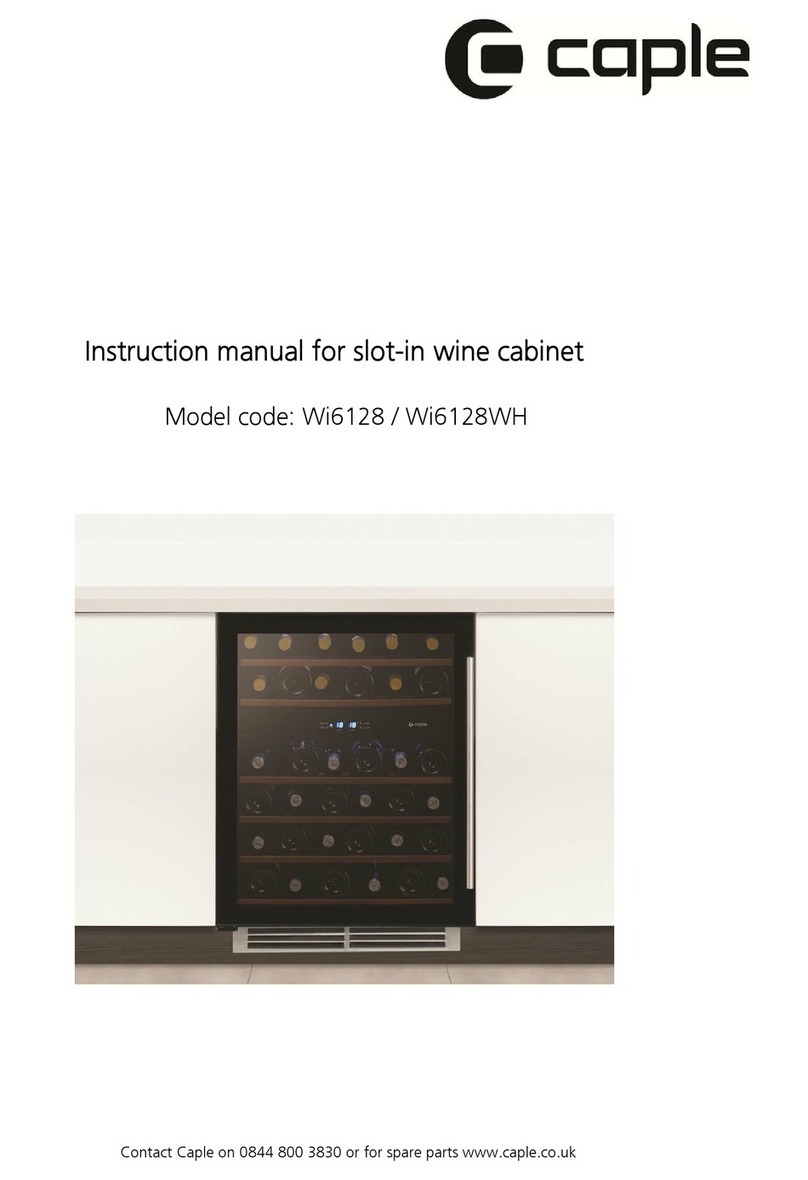

INSTRUCTIONS FOR INSTALLING INTEGRATABLE WINE COOLERS:

ONLY FRONT-VENTILATED WINE COOLERS.

1. Integrable wine coolers are front ventilated and NOT built to be fully integrated behind a fixed external door (e.g.

a cabinet door in a kitchen)

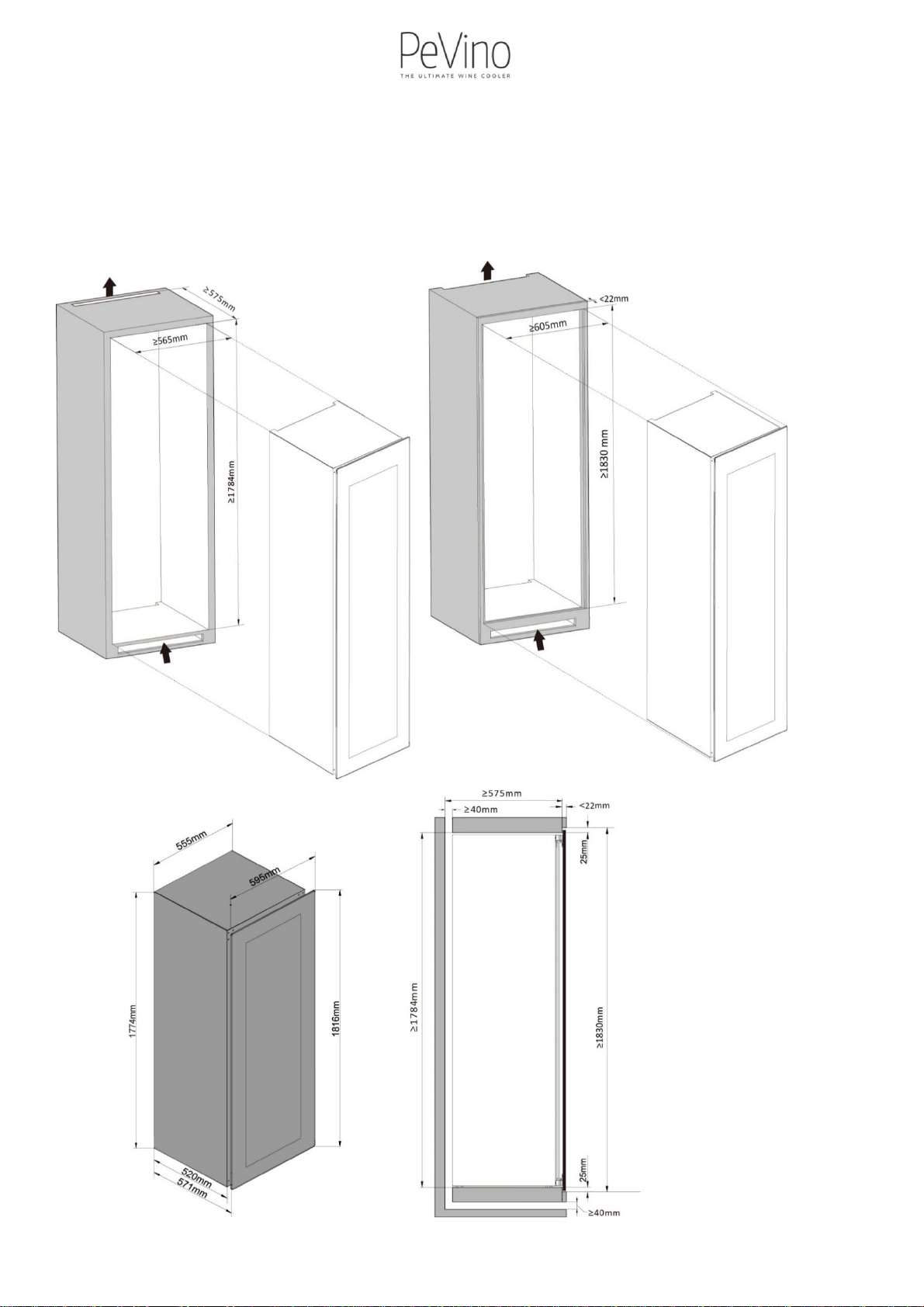

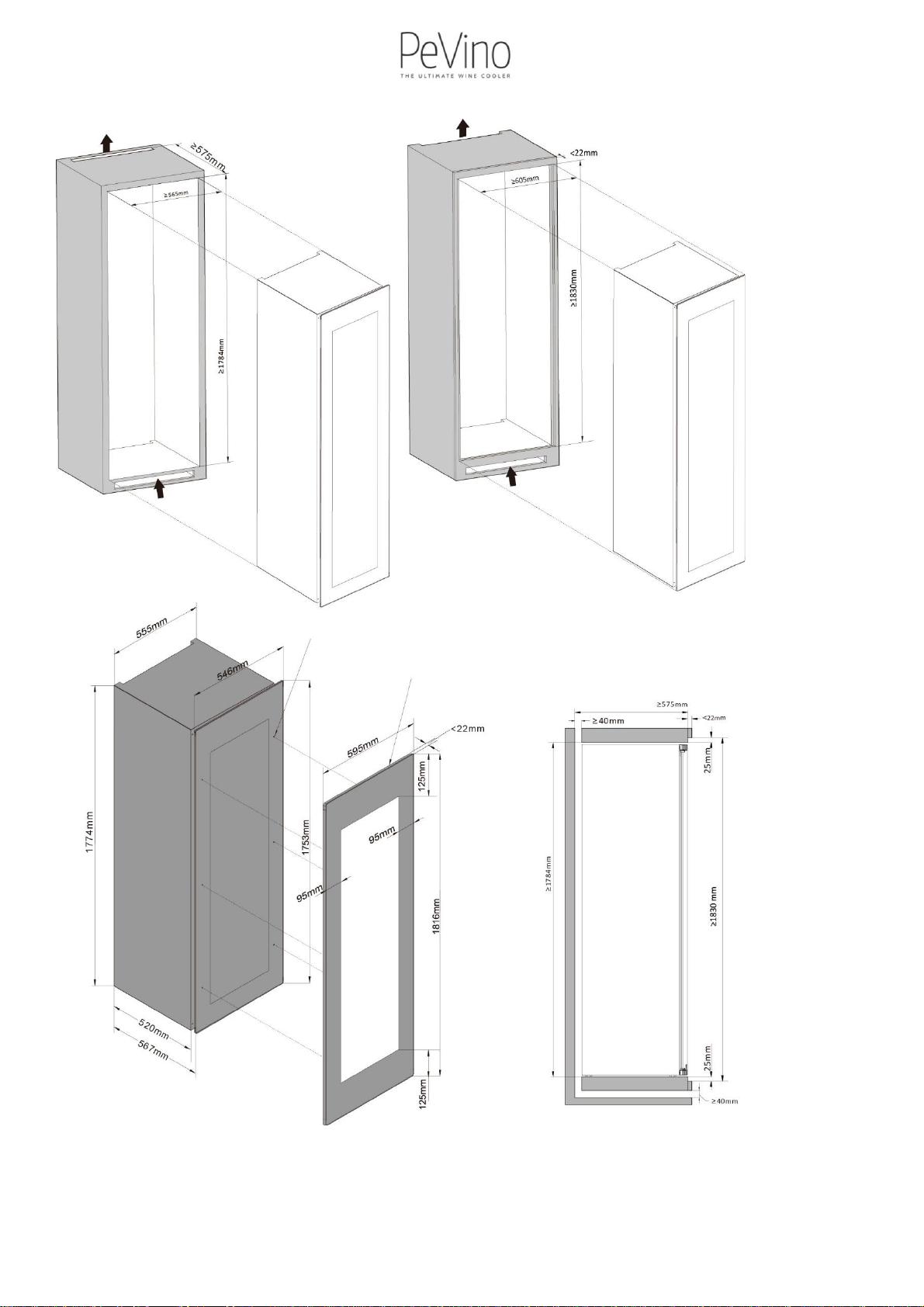

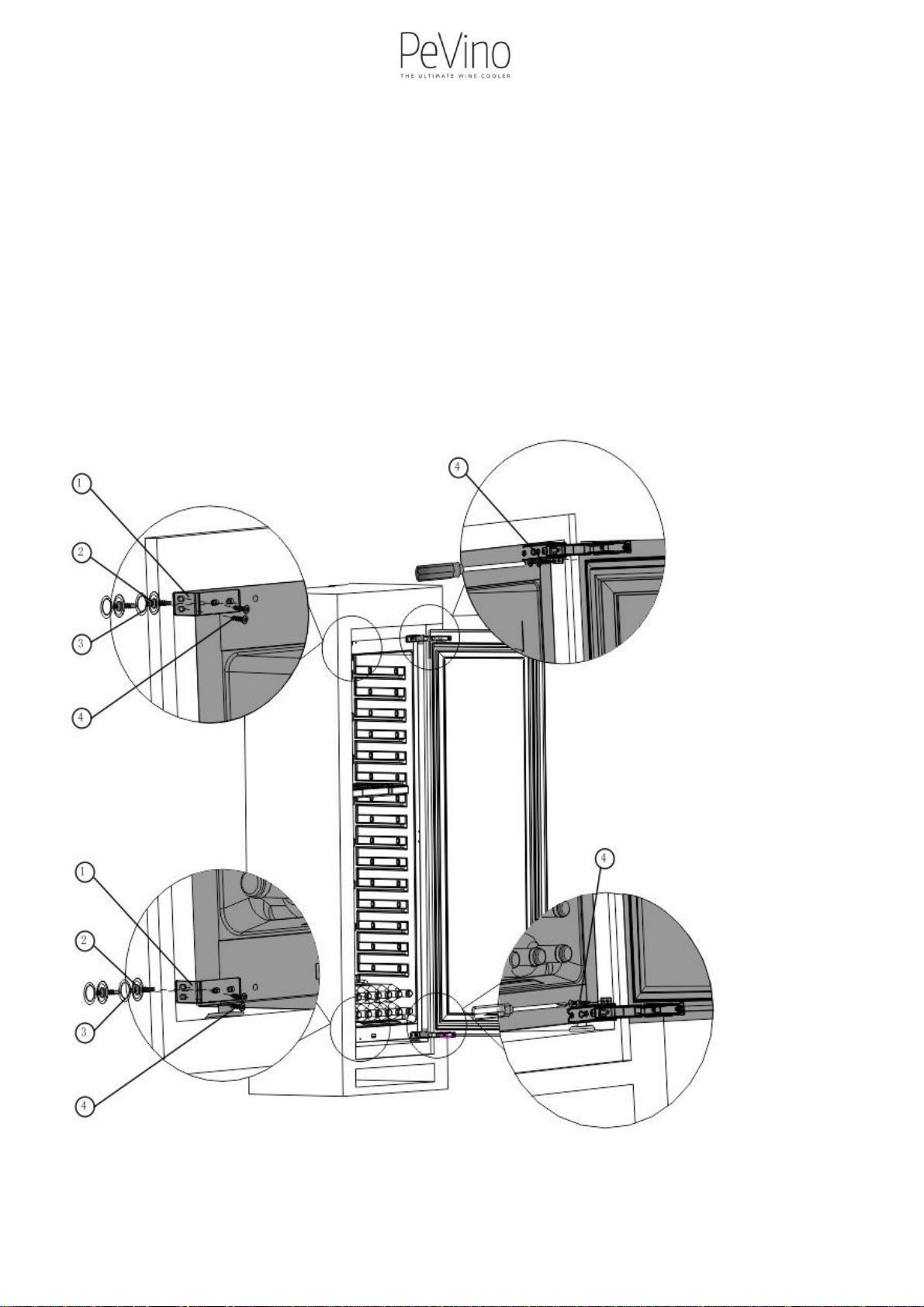

2. Follow the installation diagram when installing the wine cooler. Never go below the minimum dimension

requirements.