April 2019

4

Translation of original operating manual for

lifting points PLZW pewag winner profilift zeta

• The attached lifting device must be free to move in the ring.

• Keep lifting points clean and dry. Treat lifting points

carefully even after use. Do not let lifting points drop to the

floor as this may damage the thread or other parts.

• The base material of the object to which the lifting points

are to be attached must be strong enough to absorb the

forces that occur without deformations (proof of safety).

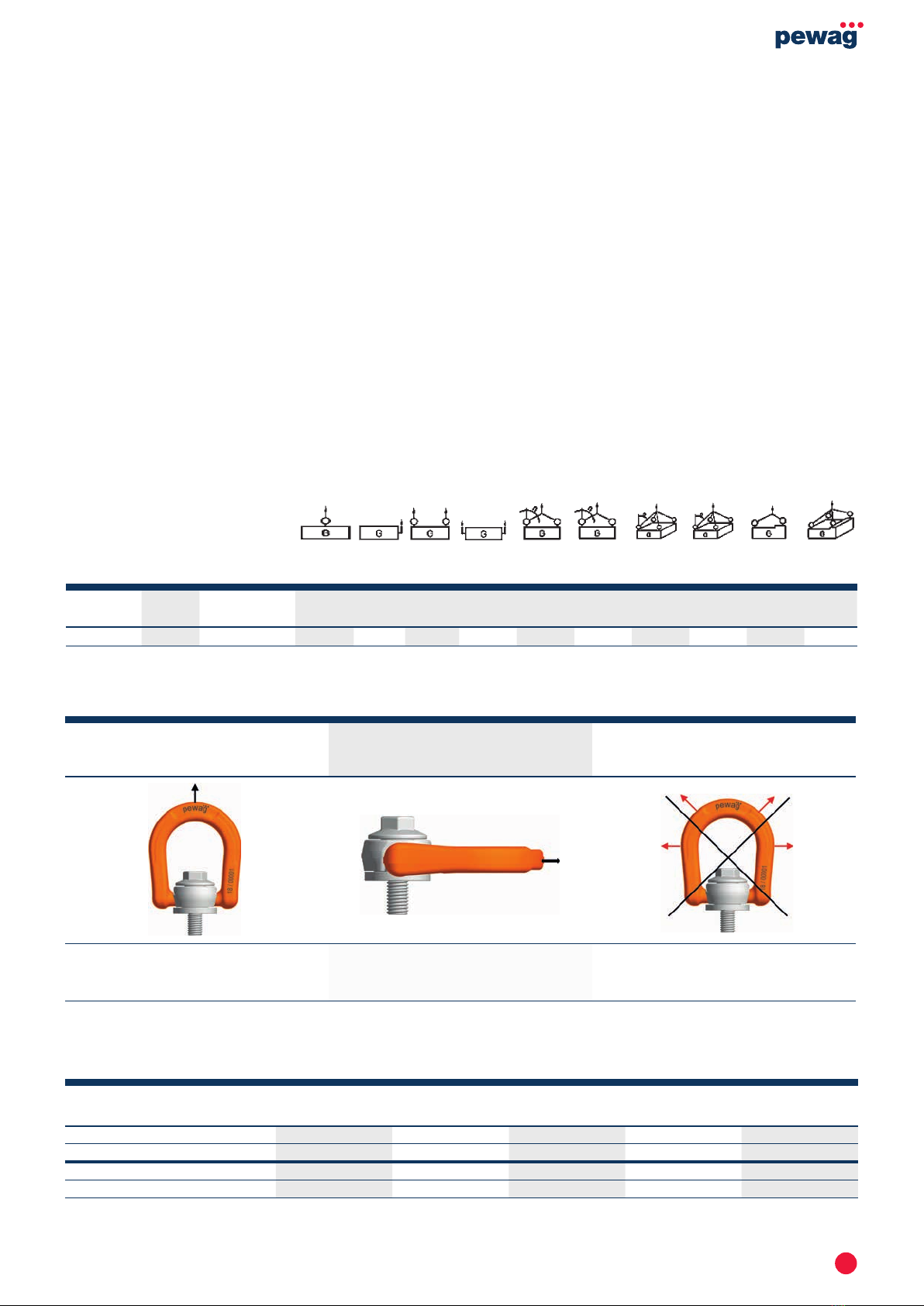

• Always choose lifting points with the correct dimension

acc. to the load capacity table, depending on the size of

the load and the constellation of the lifting devices.

• Choose the constellation of lifting points in such a way that

symmetrical loading is assured and the centre of the load

is positioned under the lifting point(s).

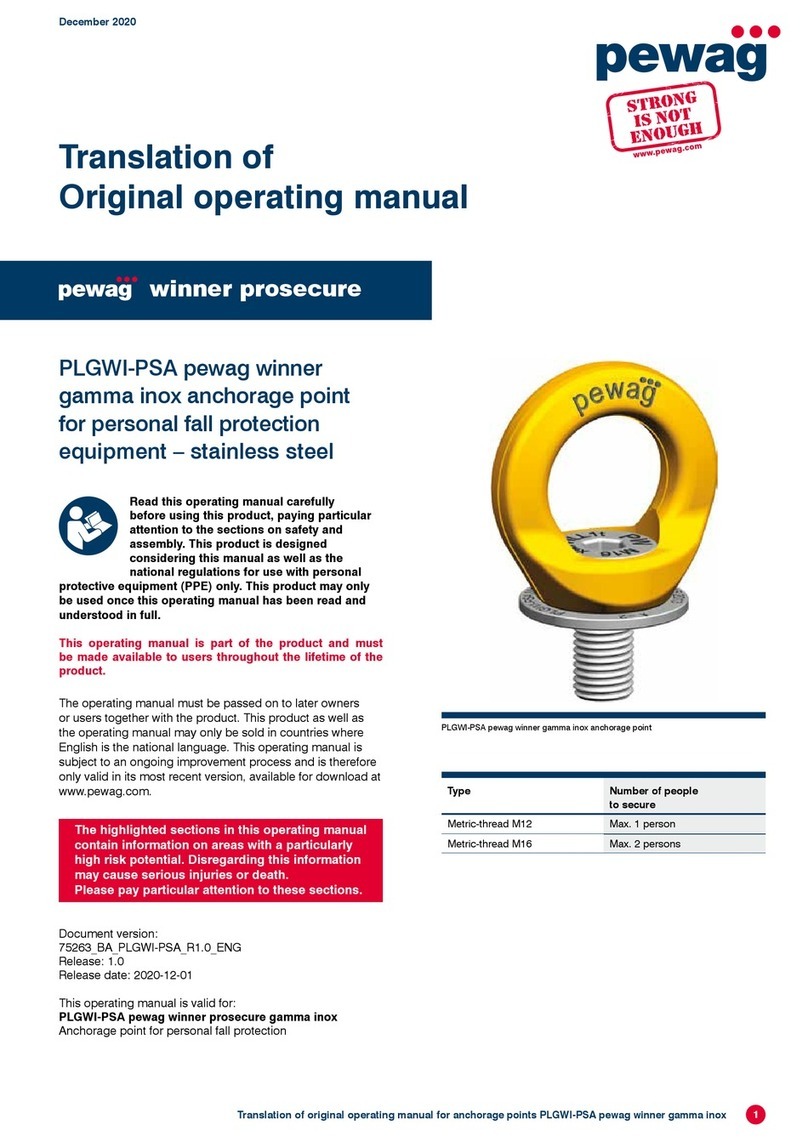

• When choosing your constellation, check that there is no

risk of improper loading due to any of the following factors:

- direction of pull is obstructed

- direction of pull is not within the indicated area (fig.1)

• Any severe conditions (see restrictions on use) must be

taken into account.

• Always take into account the user and assembly

instructions of the lifting devices used and, where

applicable, also those of the load to be lifted.

• For custom-made designs: Take into account the additional

information provided and the specifications on the

customer‘s drawings (where applicable).

• The condition as delivered must not be altered.

Surface treatments that may damage the material, welding,

heat treatments etc. are not permitted.

• The length of the thread may not be shortened.

3.2 Protective measures to be taken

by the user

Always take into account the restrictions on use and the

maximum load capacity of the lifting points used. Always

wear safety gloves when attaching the lifting device.

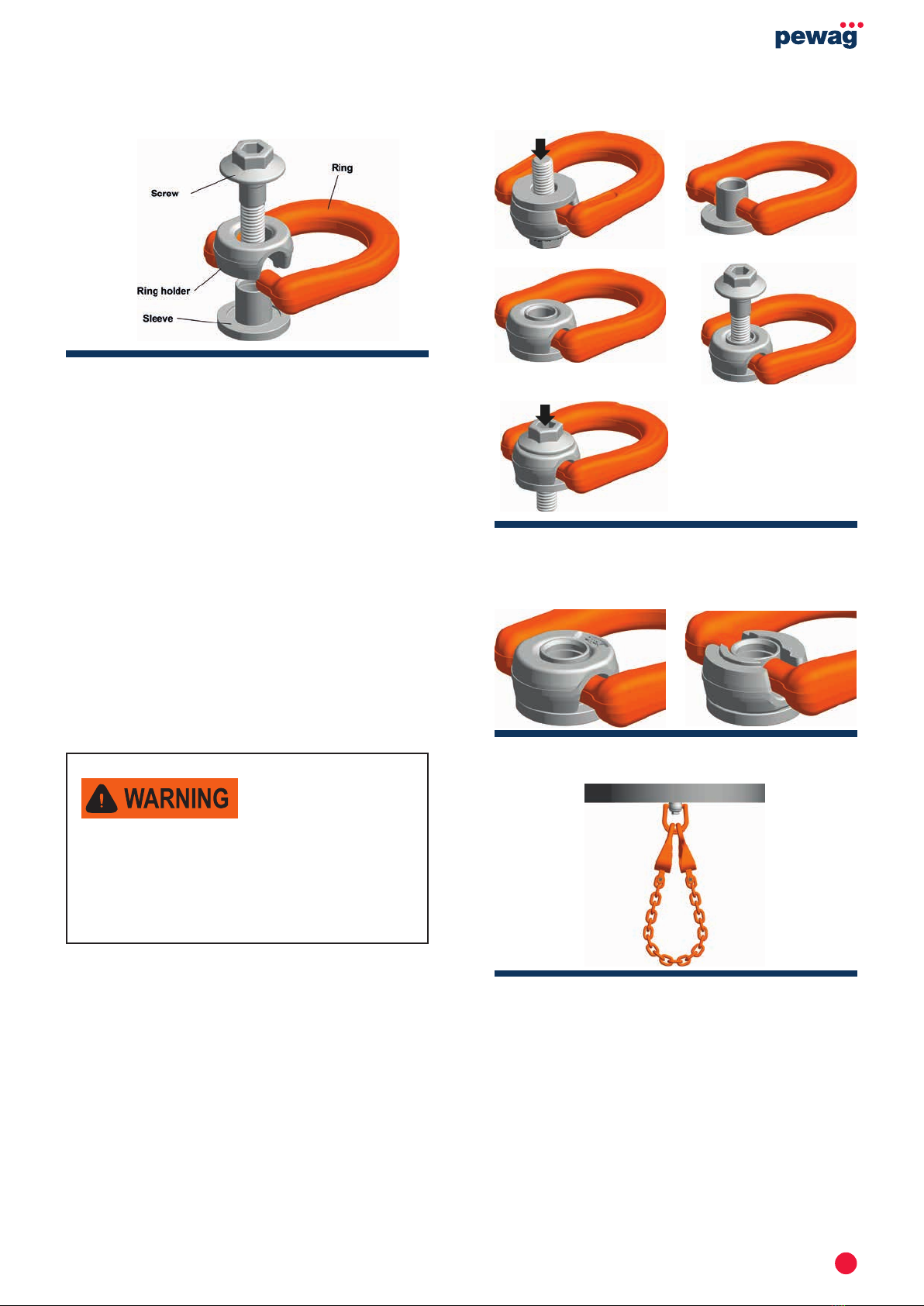

Align the lifting point in the expected direction of pull and

leave the hazard area before lifting the load. Slightly tension

the chain sling and check that the lifting devices are correctly

fitted to the lifting points and that all lifting points are correctly

aligned in the direction of pull before lifting the load.

Keep a sufficient safety

distance during the

lifting operation and

ensure that the load has been lowered safely

before removing the lifting device. Do not

overload lifting points! Falling loads may cause

injury and/or death!

3.3 Remaining risks

Overloading caused by non-compliance with the

maximum load capacity or adverse environmental factors

(temperature...). Incorrect assembly of the lifting points may

lead to failure, as may the use of non-authorised or damaged

parts of the attached lifting device.

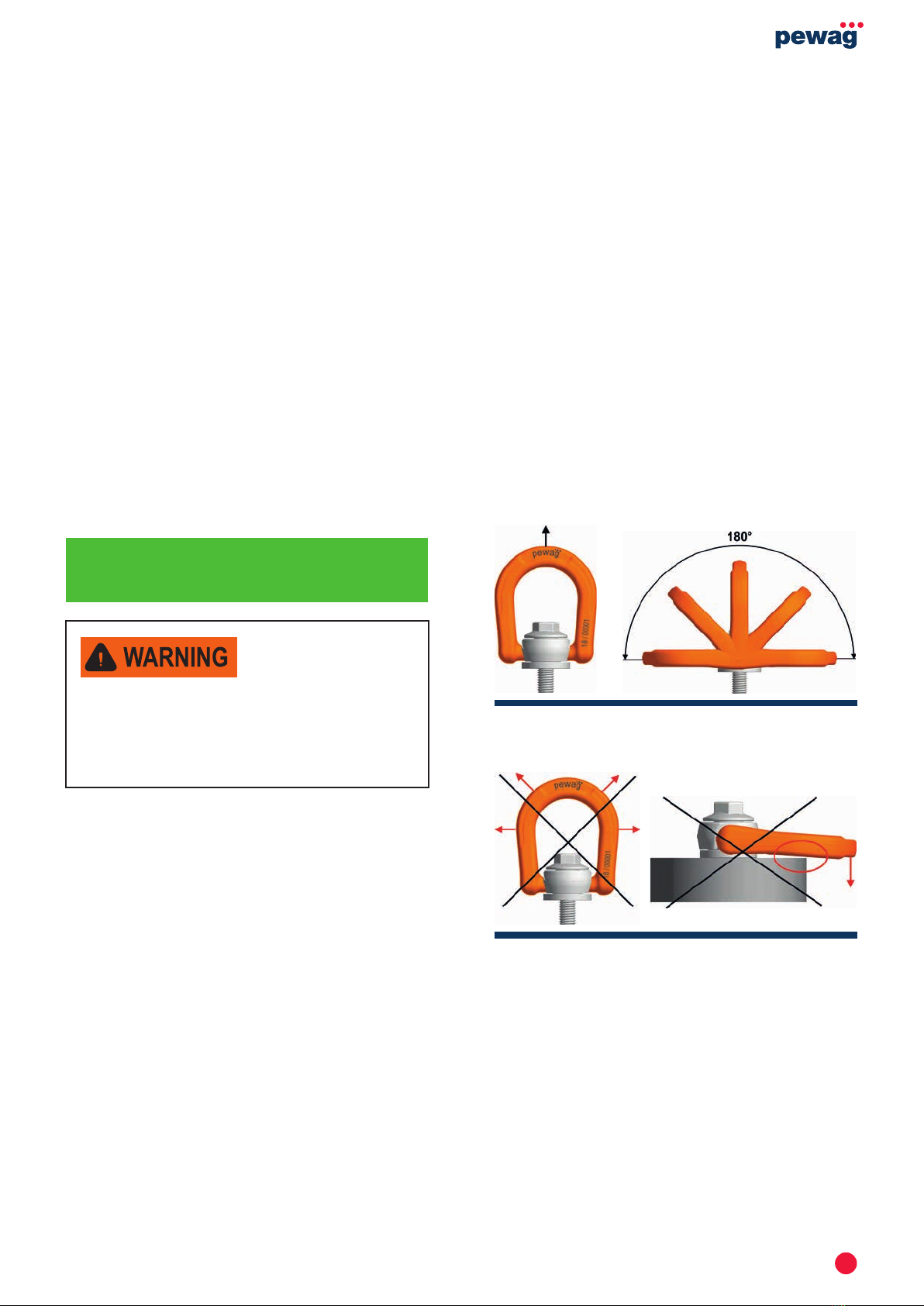

3.4 Mounting

• The screw-on surface must be level and have at least the

diameter of the contact surface of the lifting point. The

sufficiently deep, threaded hole must be at the centre of the

contact surface, at a right angle.

It must be possible to insert the screw fully

(with blind holes).

• Clean the threaded hole prior to each use and check for

damage.

• The minimum screw penetration values are:

1 x M for steel (Rm > 360N/mm²)

1.25 x M for cast steel

2 x M for aluminium

(M = thread size, e.g. M20 = 20 mm)

• Additional elements (such as washers) between the lifting

point and the load are not permitted.

• Prior to each use, ensure that the lifting point is fully screwed

in and that the contact surface is flush with the load.

• For one-off transport, it is admissible to tighten the screw

by hand using a spanner.

• If the lifting point is intended to remain permanently

attached to the load, it must be tightened with an

appropriate tool with a torque as listed in table 1. If

necessary (i.e. in case of vibrations), the thread must be

secured with a liquid threadlock (e.g. Loctite).

• After assembly, ensure that there is no risk of incorrect

loading by aligning the lifting point in the expected load

direction by moving the ring.

3.5 Dismounting

To remove the lifting point, unscrew it with a suitable tool.

Store the lifting point as described in „Storage“. Take

appropriate measures to protect the thread on the load from

damage and dirt.

3.6 Attaching closed lifting devices

to the lifting point

As this lifting point

is dismountable,

the screw is relatively

easy to remove. Always store the lifting point

carefully and correctly after use (e.g. attached to

the ring).

This lifting point may be dismounted by the user in such a

way that a closed lifting device (e.g. rope loop, eye sling

hooks) may be fitted to the ring. This process does not

require any tools and may only be performed when the lifting

point is not attached to a load.

Always wear safety gloves and work at a table so you do not

lose any parts.