INSTRUCTIONS TO BE FOLLOWED BEFORE INSTALLING THE OPERATOR

FOR OPTIMAL APPLICATION AND USE OF THE OPERATOR PLEASE READ THE INSTRUCTIONS AND CONSULT EXPLANATORY

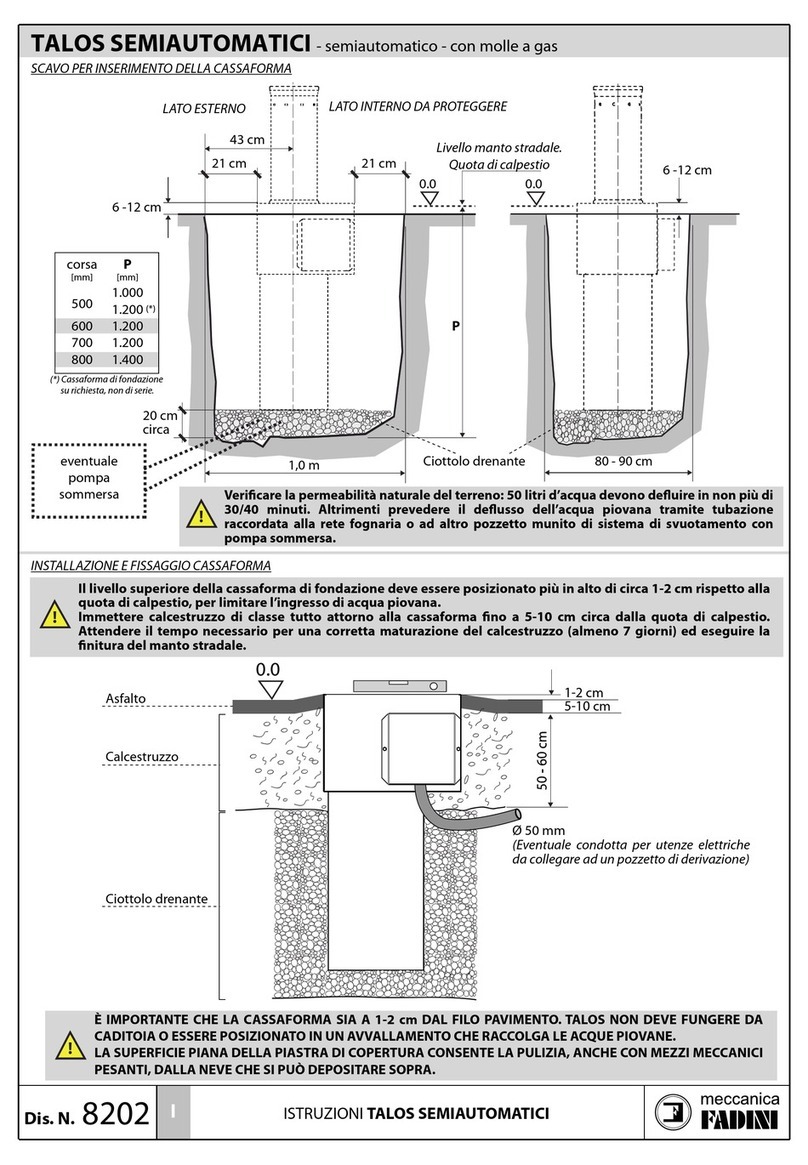

DIAGRAMS.

IMPORTANT: ALL INSTALLATION OPERATIONS MUST BE PERFORMED BY A QUALIFIED TECHNICIAN, IN OBSERVANCE OF THE

EN 12453 - EN 12445 SAFETY REGULATIONS AND MACHINERY DIRECTIVE 2006/42/CE. CAREFUL RISK ANALYSIS IS REQUIRED

UNDER APPLICABLE REGULATIONS.

OVERVIEW

This product belongs to our range of retractable traffic control posts. It is quick and easy to install, as it does not need to be

adjusted or calibrated and has been designed to regulate and prohibit vehicular access.

The oil-hydraulic bollards VIGILO 2250 (500 mm height), VIGILO 2251 (500 mm height, with LEDs), VIGILO 2263 (600 mm

height, with or without LEDs), VIGILO 2280 (800 mm height) and VIGILO 2281 (800 mm height, with LEDs) are fitted with posts

made of rust-treated steel, 200 mm diameter.

The product’s hallmark is its ease of installation: once the housing has been secured, the operator can be introduced ready for

operation, as soon as the wiring has been completed.As soon as the retractable post receives a command (from a key switch or

radio transmitter), it rises from its interred position.The post is clearly visible at nighttime thanks to a reflective strip and the

possibility of connecting a flashing light or traffic light.Versions with led lights are also available to signal when the post is in the

fully up position and when moving up or down.

Using the electronic microprocessor programmer, the operator can also be customised with presence indicator accessories

(magnetic coils, photocells).

stroke 500 mm (Vigilo 2250 and 2251)

stroke 600 mm (Vigilo 2263)

stroke 800 mm (Vigilo 2280 and 2281)

Retractable

post

Container unit inside the

housing to be sunk in a

dedicated trench in the ground

Length of cables 10 metres

Ø200

Raised post,

access prohibited pic. 1

Lowered post,

access free