2

Controls

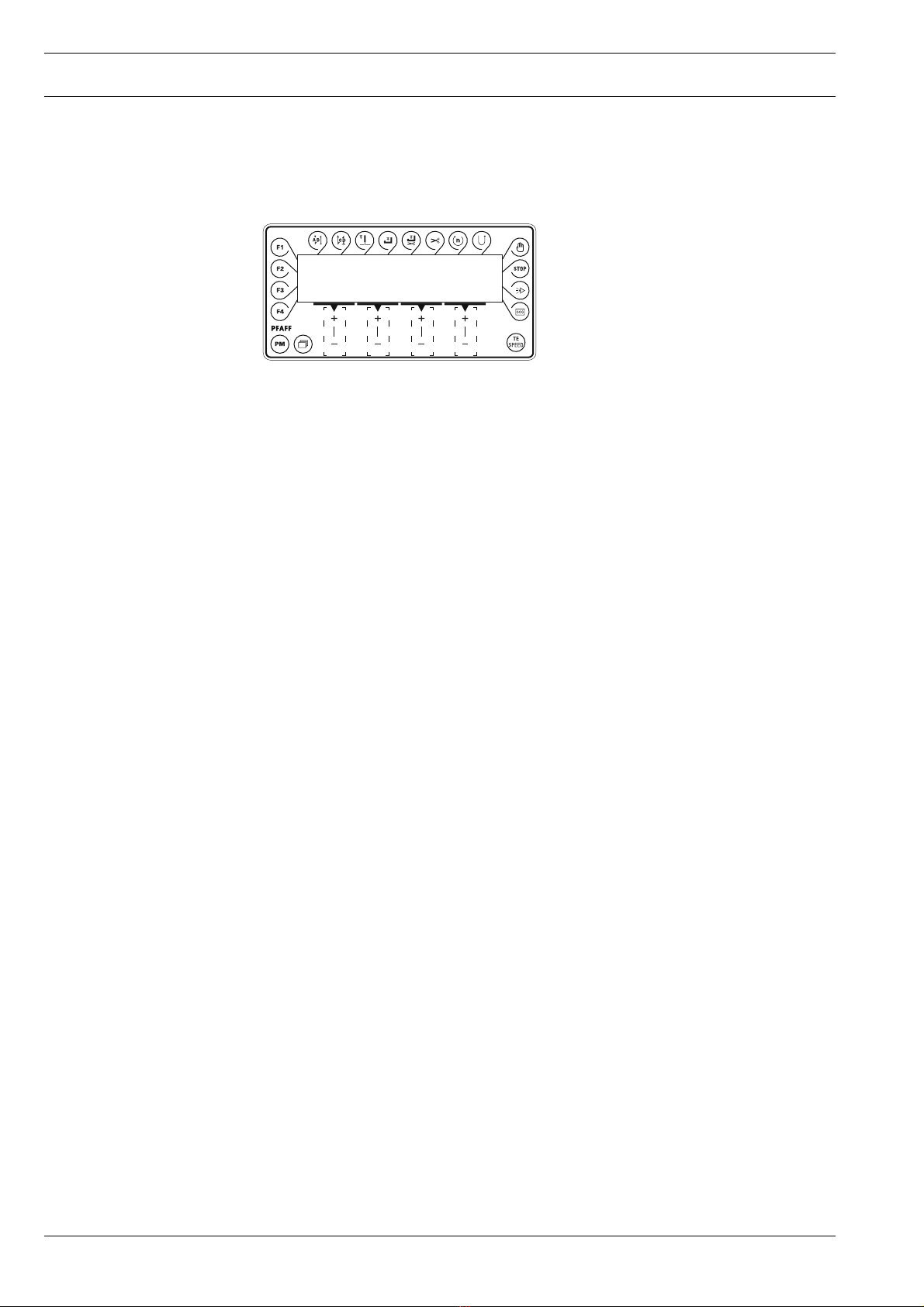

Start backtacks

●If this key is pressed, the backtacks at the beginning of the seam (start backtacks) are

switched on or off. The number of forward stitches (A) or reverse stitches (B) for the start

backtacks can be changed by pressing the +/- key underneath. To convert from double

backtack to single backtack set the number of stitches for the corresponding seam

section at zero.

End backtacks

●If this key is pressed, the backtacks at the end of the seam (end backtacks) are switched

on or off. The number of reverse stitches (C) or forward stitches (D) can be changed by

pressing the +/- key underneath. To convert from double backtack to single backtack set

the number of stitches for the corresponding seam section at zero.

Needle position

●If this key is pressed the "needle raised after sewing stop" function is switched on or off.

When the function is switched on, the needle positions at t.d.c. after sewing stops.

Foot position after stop

●If this key is pressed the "foot raised after sewing stop" function is switched on or off.

When the function is switched on, the presser foot is raised after sewing stops.

Foot position at end of seam/or after a seam segment (in programmed sewing)

●If this key is pressed the „Foot position raised at the end of a seam“ function is switched

on or off. When the function is switched on, the presser foot is raised at the end of a

seam.

Thread trimmer

●If this key is pressed the thread trimming function is switched on or off.

Speed (only in programmed sewing)

●If this key is pressed the corresponding function is switched on or off. In programmed

sewing the speed is not pedal-controlled. When the function is switched on, the speed

cannot be controlled by pedal. The machine only sews at the set maximum speed.

●When the function is switched off, the speed is controlled up to the maximum speed by

pedal

Reverse sewing (only in programmed sewing)

●If this key is pressed the corresponding function is switched on or off. When the function

is switched during programmed sewing, the corresponding seam section is sewn in

reverse.

Manual seam end (only in programmed sewing)

●If this key is pressed the corresponding function is switched on or off. When the function

is switched on, the move to the next seam section is not carried out by stitch counting or

sensor, but manually with the use of the pedal (position "-2").