Table of Contents

Contents..................................................................................Page

15 Adjustment ........................................................................................................................... 5

15.01 Notes on adjustment ............................................................................................................. 5

15.02 Tools, gauges and other accessories .................................................................................... 5

15.03 Abbreviations ......................................................................................................................... 5

15.04 Explanation of symbols.......................................................................................................... 5

15.05 Checking and adjustment aid................................................................................................. 6

15.06 Adjusting the basic machine .................................................................................................. 7

15.06.01 Machine drive home position................................................................................................. 7

15.06.02 Pre-calibrating needle height.................................................................................................. 8

15.06.03 Bottom transporter zero position ........................................................................................... 9

15.06.04 Bottom transporter sliding movement ................................................................................. 10

15.06.05 Bottom transporter stroke movement ................................................................................. 11

15.06.06 Bottom transporter height / position in needle plate cutout ................................................ 12

15.06.07 Needle in needle hole centre............................................................................................... 13

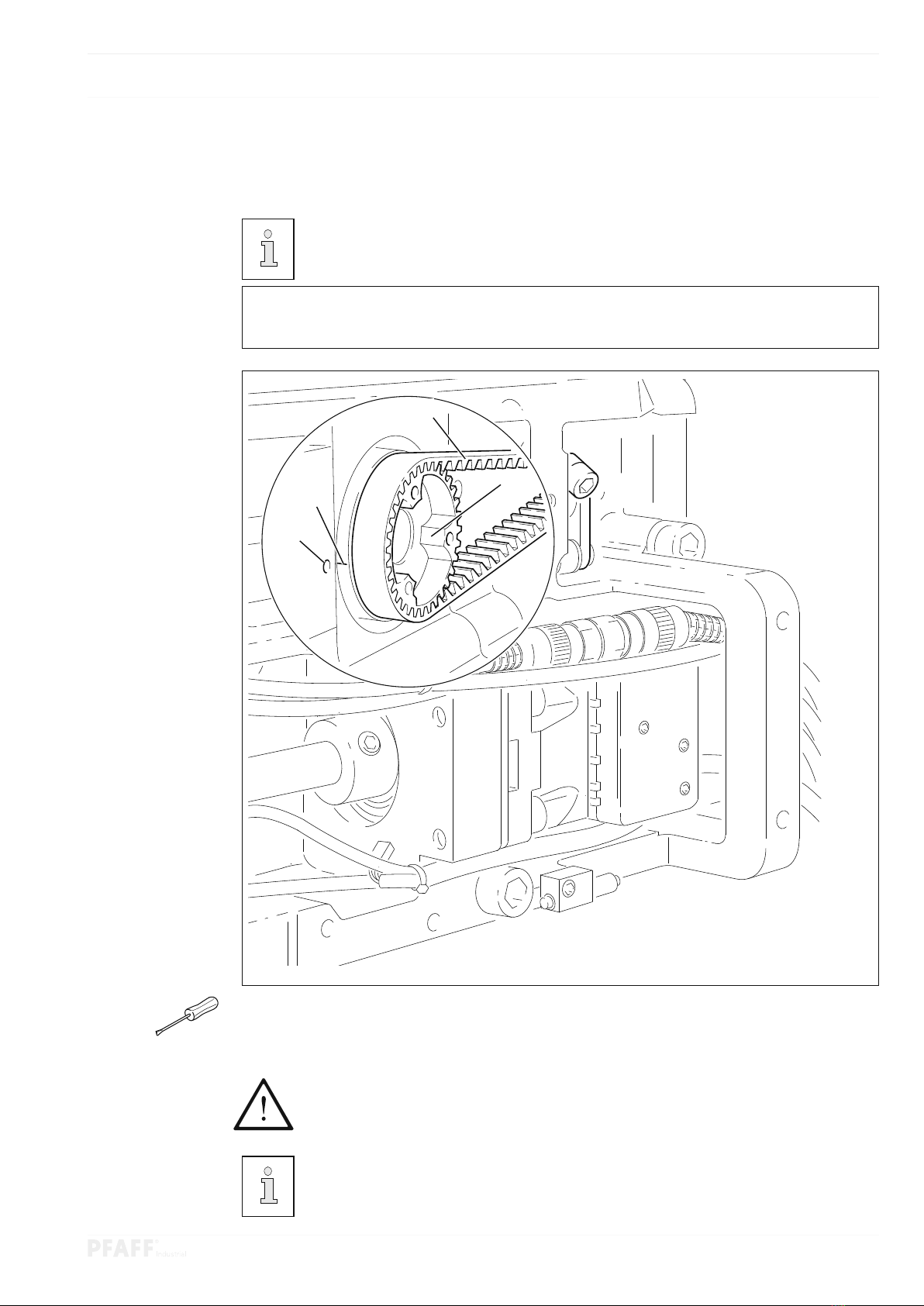

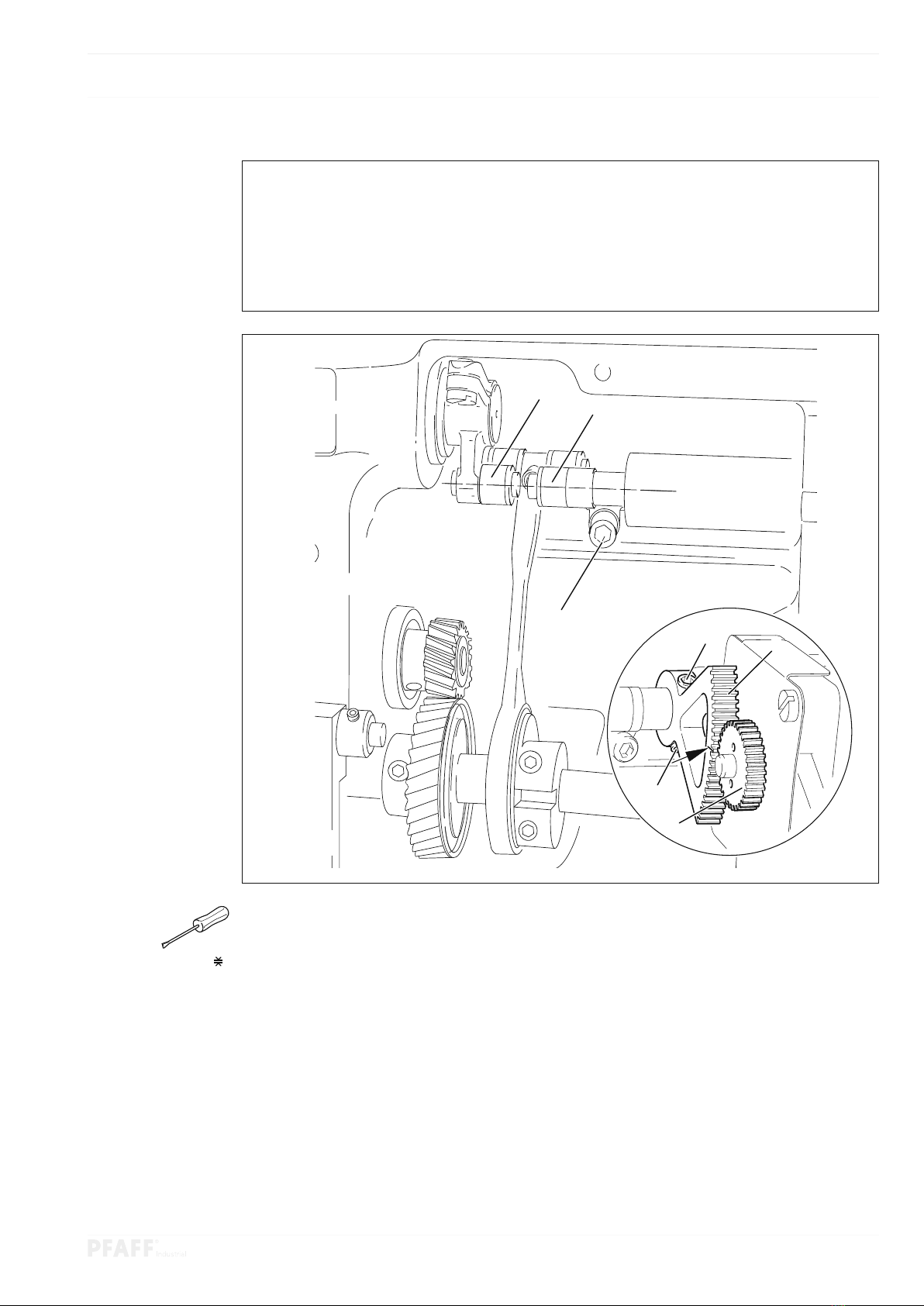

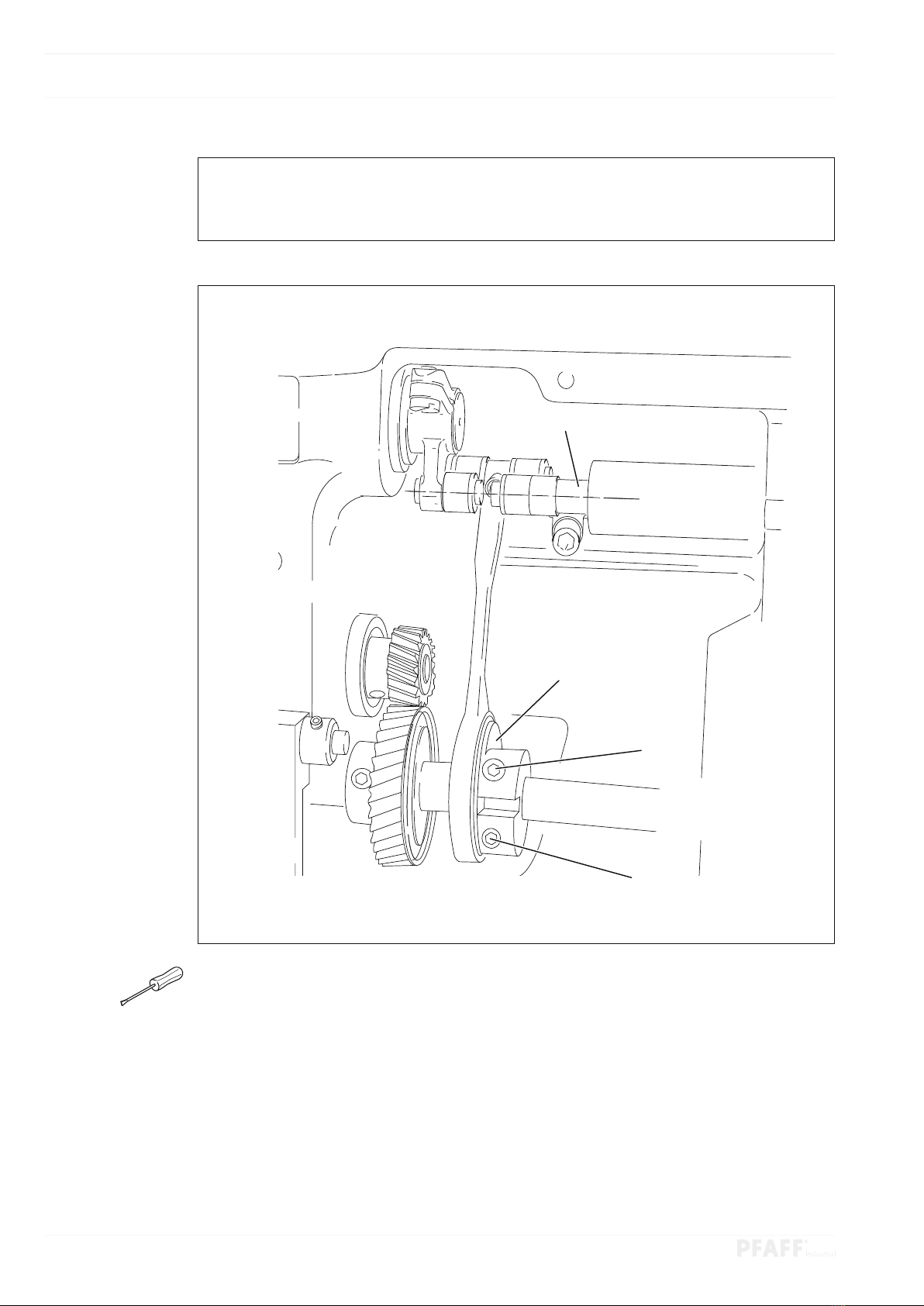

15.06.08 Hook shaft bearing and spur gear clearance........................................................................ 14

15.06.09 Hook lubrication .................................................................................................................. 15

15.06.10 Needle bar rise, hook-to-needle clearance, needle height and bobbin case position finger 16

15.06.11 Thread check spring and slack thread regulator ................................................................... 18

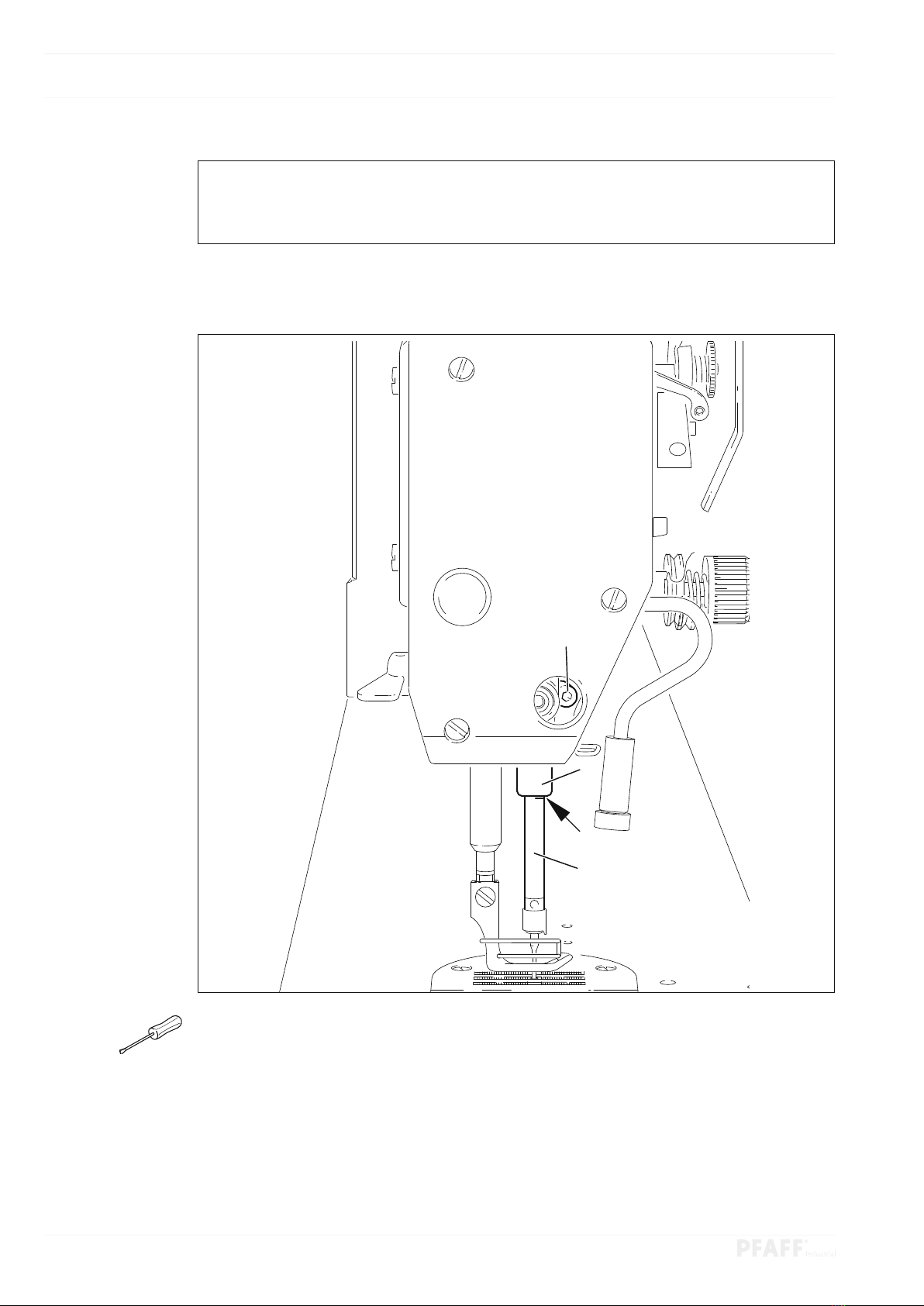

15.06.12 Passage under sewing foot.................................................................................................. 19

15.06.13 Adjusting feed regulator zero position ................................................................................. 20

15.06.14 Stitch length adjustment forwards and backwards.............................................................. 21

15.06.15 Bobbin winder...................................................................................................................... 22

15.06.16 Mechanical stitch length limitation....................................................................................... 23

15.06.17 Sewing foot pressure........................................................................................................... 24

15.07 Adjusting thread trimmer -900/24........................................................................................ 25

15.07.01 Pre-calibrating solenoid setting / control cam ...................................................................... 25

15.07.02 Aligning thread catcher laterally ........................................................................................... 26

15.07.03 Knife position ....................................................................................................................... 27

15.07.04 Front turning point of thread catcher.................................................................................... 28

15.07.05 Manual cutting control ......................................................................................................... 29

15.07.06 Needle thread tension release............................................................................................. 30

15.07.07 Re-calibrating control cam.................................................................................................... 31

15.08 Aligning transmitted light transmitter................................................................................... 32

15.09 Adjusting transmitted light sensors ..................................................................................... 33

15.10 Functional check of bobbin thread monitor .......................................................................... 34