Pfannenberg Rack Series Manual

English

1

Operating and Maintenance Instructions

MANUFACTURER

DASSI S.r.l. –Member of the Pfannenberg Group

Via La Bionda, 13 I-43036 Fidenza (PR)

Tel. +39 0524-516711 Fax. +39 0524-516790

English

Operating and Maintenance Instructions

Deutsch

( Übersetzung

Originalbetriebsanleitung )

Betriebs - und Wartungsanleitung

Italiano

( Traduzioni delle istruzioni

originali )

Libretto di istruzioni e assistenza

Español

( traducción

de las instrucciones originales )

Libro de Instrucciones

Français

(traduction

de la notice originale )

Cahier d’Instructions

Русский

( перевод

из первоначальных

инструкций )

Инструкция по эксплуатации

Rack series

CC series

EB small

EB big series

EB extensions series

AR series

HK series

PWW series

VLV series

English

2

Pfannenberg Service Company

ITALY

Pfannenberg Italia s.r.l.

Via La Bionda, 13 I –43036 FIDENZA (Parma)

Tel. +39 0 524 / 516-711 –Fax +39 0 524 / 516-792

info@pfannenberg.it -www.pfannenberg.com

GERMANY

Pfannenberg GmbH

Werner-Witt-Straße 1. D -21035 Hamburg

Tel. +49 40 / 73412-105 –Fax +49 40/ 73412-101

info@pfannenberg.com - www.pfannenberg.com

U.S.A.

Pfannenberg Inc

68 Ward Road. Lancaster, NY 14086

Tel. +1 716 / 685-6866 –Fax +1 716 / 681-1521

info@pfannenbergusa.com -www.pfannenberg.com

CHINA

Pfannenberg (Suzhou) Pte Ltd

5-1-D, No.333 Xingpu Road

Modern Industrial Park, SiP,

Suzhou 215021, Jiangsu Province, P.R.C

Tel: +86-512 6287 1078 –Fax: +86-512 6287 1077

info@pfannenberg.cn -www.pfannenberg.cn

ASIA

Pfannenberg Asia Pacific Pte Ltd

61 Tai Seng Avenue

# B1-01 UE Print Media Hub

Singapore 534167

info@pfannenberg.com - www.pfannenberg.com

For Service, please contact the nearest Pfannenberg Service Compa

English

3

Index

1. Warranty

2. Safety

3. Residual risks

4. Receiving and Unpacking

5. Positioning the Chiller

6. Foundation

7. Connections

8. Process Water / Fluids

8.1 Waterquality

9. Process Oil / Fluids

10. Ambient temperature

11. Start up of the chiller

Debug Table

APPENDIX A1

APPENDIX A2

APPENDIX B1

APPENDIX B2

APPENDIX C

1Close Loop Chiller Start-up

2Water - water Chiller Start-up

1. Warranty

This warranty covers the material design and quality during the first 12 months starting from the delivery date. Within this

defined period our Company will either repair, or replace (with ex works delivery) all parts which on the sole opinion of the

supplier, have caused quality problems which are not a result of poor maintenance, inexperience of the operators, faulty

installation or failures which are caused because this instruction was not followed. This warranty does not include the expenses,

travel hours and travel allowance related to our technicians in case their presence is required at the customer's factory. These

expenses will be totally invoiced as working hours. The customer shall not have the right to claim any refund from our Company

for the time during which the machine shall remain inactive, related to repairs. No refund will be acknowledged for expenses,

damages, either direct or indirect, which are a result of the above.

Separate agreements with customers have to be agreed in written form may vary from this paragraph.

2. Safety

The Chiller instructions must be read by the installer and personnel in charge for operation, before starting the chiller.

All safety and security instructions given in this manual have to be observed!

Only qualified personnel are allowed to install, operate and do the maintenance work.

Non observance of the instructions may cause injuries and will cancel the manufacturers liability for subsequent damage.

National regulations on accident prevention, regulations of the local power supply authorities as well as any specific safety

instructions for chiller must be observed.

The safety of the unit is only guaranteed, if it is used as intended.

The following points must be observed before commissioning and while operating the Chiller:

Familiarize yourself with all operating controls.

Make sure that all working limits indicated within unit label are observed.

Use protective devices to check electrical insulation. Do not carry out any work on any part of the equipment that might

be live with wet clothing, hands and feet.

Never spill or pour any cooling medium into the environment as this may cause health hazard.

The components of the Chiller must not be modified in any way.

Disconnect the power supply and release pressure from any pressurized component before carrying out any service

work on the Chiller.

A qualified commissioning engineer must ensure that the Chiller has been connected to the electrical mains in

accordance with the standard EN 60204 and all other applicable national regulations.

English

4

For Health and Safety reasons, please find below a list of potential risks that the operator is exposed to while commissioning

and/or operating and/or dismantling the unit:

Risk

Recommended Safety Measure

Residual Risk to be aware of

sharp edges (such as heat

exchanger fins and internal

metal plates live edges)

It is recommended to use safety equipment

(such as gloves and protective cloths)

-

hot surfaces

(such as electric motor body of

pump or compressor and

refrigeration copper pipes)

It is recommended to use safety equipment

(such as gloves and protective cloths)

-

refrigerant under pressures up

to 30 bar (435 PSI) within

refrigeration circuit

Always verify functionality of High Pressure

Switch.

Never open refrigeration circuit for

maintenance before releasing pressure*

Due to Toxicity of refrigerant

and oil still inside circuit, it is

recommended to use suitable

gloves and mask while

servicing refrigerant

equipment.

cooling water/glycol mixture

under pressures up to 5,8 bar

(85PSI) within hydraulic circuits

(PWW series: PS = 12 bar)

Always check that all cooling water/glycol

pressure is released before sectioning and

servicing hydraulic equipment using purging

system and refill ball valve

Due to Toxicity of glycol and oil

still inside circuit, it is

recommended to use suitable

gloves and mask while

servicing hydraulic equipment

electrical shock

Always disconnect power supply and post a

‘MAINTENANCE WORK IN PROGRESS’

sign on a visible position next to the main

switch during service

-

rotating fans

Always disconnect power supply and make

sure all mechanical equipment is stopped

before service.

-

Toxicity of refrigerant and

cooling liquid

It is recommended to use suitable protection

equipment (such as gloves, glasses, safety

shoes)

-

English

5

*NOTE: for environmental reasons never discharge refrigerant into atmosphere (follow local regulations to properly dispose of

refrigerant).

It is recommended to familiarize with all technical documentation provided with the unit (such as Mechanical & Electrical

Diagrams) in order to avoid improper operation of this unit.

It is also mandatory to comply with Regulation (EC) No 842/2006 of the European Parliament and of the Council of 17 May

2006 on certain fluorinated greenhouse gases.

The above mentioned Regulation lays down specific measures and restrictions to be considered while commissioning,

operating, maintaining and disposing any equipment containing greenhouse gases, such as HFCs, as specified in Annex I.

The Regulation (EC) No 842/2006 also (but not only) specifies mandatory leakage-check frequency to be performed by certified

personnel and mandatory records providing the evidence of exact fluorinated gas charge and subsequent added and/or

recovered quantities as described in Article 3 (reported below):

Article 3 Containment

Operators of the following stationary applications: refrigeration, air conditioning and heat pump equipment, including their

circuits, as well as fire protection systems, which contain fluorinated greenhouse gases listed in Annex I, shall, using all

measures which are technically feasible and do not entail disproportionate cost:

(a) prevent leakage of these gases; and

(b) as soon as possible repair any detected leakage.

Operators of the applications referred to in paragraph 1 shall ensure that they are checked for leakage by certified personnel

who comply with the requirements of Article 5, according to the following schedule:

(a) applications containing 3 kg or more of fluorinated greenhouse gases shall be checked for leakage at least once every 12

months; this shall not apply to equipment with hermetically sealed systems, which are labeled as such and contain less than 6

kg of fluorinated greenhouse gases;

(b) applications containing 30 kg or more of fluorinated greenhouse gases shall be checked for leakage at least once every six

months;

(c) applications containing 300 kg or more of fluorinated greenhouse gases shall be checked for leakage at least once every

three months.

The applications shall be checked for leakage within one month after a leak has been repaired to ensure that the repair has

been effective.

For the purposes of this paragraph, ‘checked for leakage’ means that the equipment or system is examined for leakage using

direct or indirect measuring methods, focusing on those parts of the equipment or system most likely to leak. The direct and

indirect measuring methods of checking for leakage shall be specified in the standard checking requirements referred to in

paragraph 7.

Operators of the applications referred to in paragraph 1, containing 300 kg or more of fluorinated greenhouse gases, shall install

leakage detection systems. These leakage detection systems shall be checked at least once every 12 months to ensure their

proper functioning. In the case of such fire protection systems installed before 4 July 2007, leakage detection systems shall be

fitted by 4 July 2010.

Where a properly functioning appropriate leakage detection system is in place, the frequency of the checks required under

paragraph 2(b) and (c) shall be halved.

In the case of fire protection systems where there is an existing inspection regime in place to meet ISO 14520 standard, these

inspections may also fulfill the obligations of this Regulation as long as those inspections are at least as frequent.

Operators of the applications referred to in paragraph 1, containing 3 kg or more of fluorinated greenhouse gases, shall

maintain records on the quantity and type of fluorinated greenhouse gases installed, any quantities added and the quantity

recovered during servicing, maintenance and final disposal. They shall also maintain records of other relevant information

including the identification of the company or technician who performed the servicing or maintenance, as well as the dates and

results of the checks carried out under paragraphs 2, 3 and 4 and relevant information specifically identifying the separate

stationary equipment of applications referred to in paragraph 2(b) and (c). These records shall be made available on request to

the competent authority and to the Commission.

Regulation (EC) No 842/2006 also include: ‘Scope’ –Article 1; ‘Definitions’ –Article 2; ‘Recovery’ –Article 4; ‘Training and

Certification’ –Article 5; ‘Reporting’ –Article 6; ‘Labelling’ –Article 7; ‘Control of Use’ –Article 8; ‘Placing on the Market’ –

Article 9; ‘Review’ –Article 10; Article 11; ‘Committee’ –Article 12; ‘Penalties’ –Article 13; Article 14; ‘Entry into force’.

CAUTION: in accordance to the F-GAS regulation DRP43/2012, every year the operator (the owner of

the equipment) is responsible to ensure a Gas leakage test, the recording of the gas quantity change inside the unit

and the communication to the responsible agency of the state in the European community where the unit is in

operation.

Please ask Pfannenberg service in case support is needed

English

6

3. Residual risks

There are some residual risks after the installation of the unit that have to be considered:

Residual risks according to 2006/42/CE Directive:

The condenser has fins on his external surface, so there is the possibility for the operator to touch sharp edges

during service of the unit.

Although the unit is designed with all the possible safety requirements, in case of external fire there is the

possibility that the internal pressure and temperature of the unit will increase in a dangerous and uncontrollable

way; in that case use the extinguishing tools suitable for that conditions.

Residual risks according to 97/23/CE Directive:

Although the unit is designed with all the possible safety requirements, in case of external fire there is the

possibility that the internal pressure and temperature of the unit will increase in a dangerous and uncontrollable

way; in that case use the extinguishing tools suitable for that conditions.

For the series production of the standard units of category , the pressure resistance test (typically the

hydrostatic pressure test) is made on a statistic base, not on all units.

This can be accepted, also considering all the safety devices mounted on the units.

4. Receiving and Unpacking

Each unit is packed in a carton box.

It is recommended to pay particular attention during handling and transportation of the unit and to maintain the packaged units

in the vertical position, in order to avoid any kind of dents to the external frame and any damage to the internal components.

Secure units to the transport vehicle with suitable strapping.

Note! The above mentioned packages are not suitable for piling up units on top of each other

Store the Chiller in a dry place, away from heat sources. All waste materials should be recycled in the appropriate manner.

For the operations of lifting and movement it is necessary to use a fork lift truck with proper load capacity and with forks longer

than the base of the Chiller. Avoid sudden movements which can damage the framework and the internal components.

PFANNENBERG Std Chiller (above 45Kg weight) are also provided with 4 eye bolts for lifting and transportation; to be used for

vertical loading/unloading only (to see the right point for lifting please refer to the stickers on the unit).

Check after the final positioning of the Chiller the internal connections to avoid damage during operation.

EB Models

Packaging solution

EB 30 –43 –60 WT

EB 75 –90 WT

EB 130 –150 WT

Chiller supplied on a wooden

pallet and protected by

a cardboard box

EB 190 –250 WT

EB 300 –350 –400 WT

Chiller supplied on a wooden

pallet and wrapped

with protective film

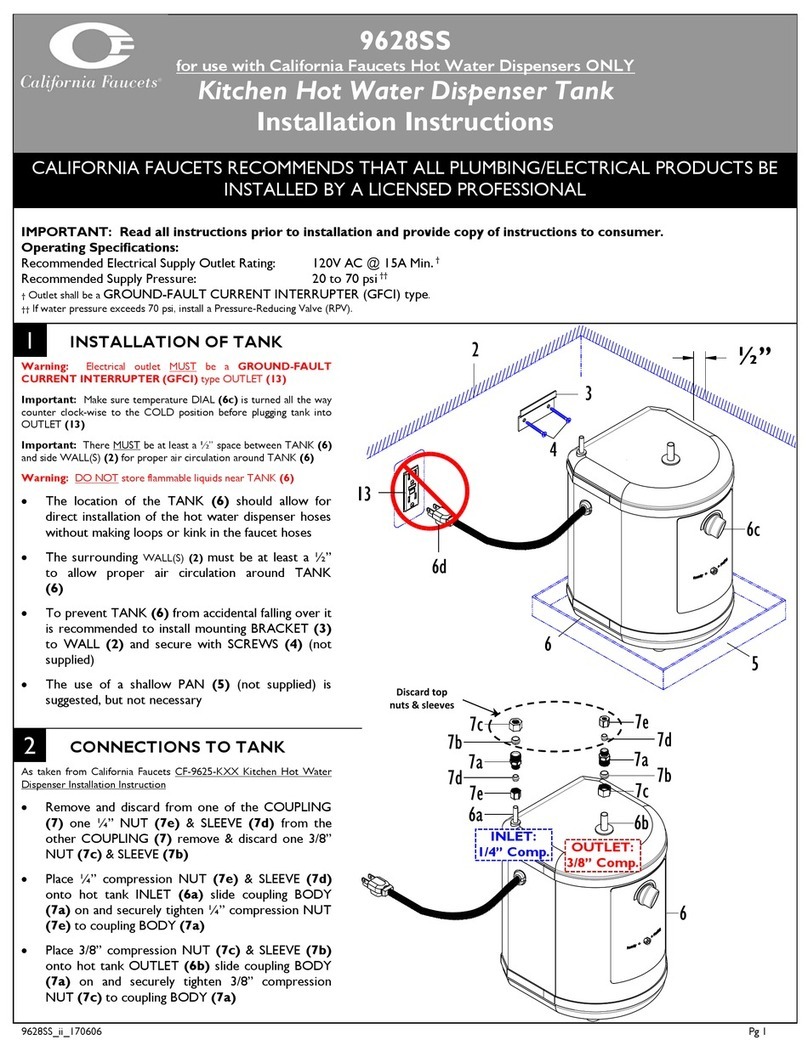

Picture 1 –Chiller lifting

English

7

5. Positioning the Chiller

Place the Chiller in an area shielded from any possible manufacturing residuals (shavings, dust, etc.) and well-ventilated, away

from heat sources and direct influence of sun light ; if possible, near the user system, in order to avoid load losses along the

hydraulic connection pipes. Use the adjustable feet to level off the cooling unit.

The customer has to place a suitable room at disposal, as shown in the figure:

Picture 2 –Room minimum dimensions, x=h=1.5 m

According to the CEI EN 60204-1, the unit is provided with a lockable main switch which is not positioned at a minimum

distance of 0,6 m from the basement of the unit, so it’s recommended to install the unit in a position that allows the main switch

to maintain that minimum distance from the floor.

CAUTION: For standard unit the outdoor installation is absolutely forbidden, even if under a roof.

Only special designed outdoor units can be used in outdoor installation.

For regular maintenance or adjustment, the chiller shall be located between 0,3 m and 1,0 m above the servicing

level.

6. Foundation

PFANNENBERG chillers should be set on a concrete slab. The slab should extend a minimum of 30cm (12 inches) beyond the

perimeter of the Chiller to prevent damage from lawn maintenance equipment, etc. The Chiller, which should be level and

properly anchored, is provided with 4 antivibration dampers on the bottom of the unit, which allow the support and the fixing of

the Chiller and to dampen the vibrations and decrease the noise during the operation.

English

8

7. Connections

WARNING: Hydraulic connections are the first ones to be assembeled during installing operation, to

be followed by electric connections. Remove the caps inside the hydraulic fittings connection before to connect the

chiller to your device.

WARNING: The chillers has been cleaned by means of specific cleaning products. The eventual

findings of solid particles in the hydraulic system might cause the loss of warranty.

Hydraulic connections. For the hydraulic connection please refer to the enclosed hydraulic plan. The flow rate and the fluid

circulation direction must be respected during connection in accordance with INLET-OUTLET identification plates.

CAUTION: Fill the tank before connecting Hydraulic tubes (as described in the start-up procedure).

Remove the caps inside the hydraulic fittings connection before to connect the chiller to your device.

Example of Hydraulic connection plate

Picture 3 –Hydraulic connection plate

English

9

CAUTION: In case of unit with tank, please fill the tank before connecting Hydraulic tubes.

Example of Electric connections

The unit must be electrically connected by the customer

Please Note:

Electrical installation must respect all valid safety standards.

It’s advisable to install a magnetic-thermal cutout upstream power cable.

Make sure the system is adequately earthed.

Check that the voltage and frequency of the power supply correspond to the specifications on the unit’s data plate

and/or enclosed electrical plan.

Pfannenberg Chiller units are designed for TN Earthing Systems. Use the Maximum fault loop Chiller Impedence value

for sizing purposes on site (refer to Zpe value specified within Electrical Diagram attached)

For Rack series provide the switch-disconnector in accordance with IEC 60947-1, IEC 60947-2, IEC 60947-3.

Picture 3.b –Hydraulic connection plates (PWW )

Secondary circuit

„application side“

Connection 3/4“ (PWW 9000-12000)

Connection 1“ (PWW 18000-24000)

OUT

IN

OUT

IN

Primary circuit

„facility side“

Connection 3/4“ (PWW 9000-12000)

Connection 1“ (PWW 18000-24000)

Picture 4 –Electric

connection plate

English

10

CAUTION: In case units that can work with different voltages (400V or 460V), connect the transformer

of the auxiliary circuit located inside the e-box in the right way.

Unit CE: Factory setting 400/3/50, see picture 5

Unit UL: Factory setting 460/3/60, see picture 6

Voltage Limitations:

Pfannenberg standard Chiller operation is guaranteed within these ranges:

Nominal voltage ±10 %

Nominal frequency ±1 %

Please refer to the type label to see which are the operating nominal conditions of the unit.

Nominal conditions

V min

[V]

V max

[V]

f min

[Hz]

f max

[Hz]

230 V / 1 ~ / 50 Hz

207

253

49.5

50.5

230 V / 1 ~ / 60 Hz

207

253

59.4

60.6

400V / 3~ / 50Hz

360

440

49.5

50.5

460V / 3~ / 60Hz

414

506

59.4

60.6

8. Process Water / Fluids

PFANNENBERG chillers should be filled to the proper level with an inhibited glycol designed for Industrial chillers systems. Do

not use automotive antifreeze! The inhibitors used in automotive antifreeze can break down quickly and accelerate the

degradation of the coolant base (glycol); as well as promote corrosion in a system. Silicates used in automotive antifreeze coat

heat exchangers, resulting in reduced heat transfer. Also, silicates can gel causing fouling and plugging of a system.

The ratio of inhibited glycol to water should be adequate to prevent freezing at the lowest ambient temperature. Check the level

with all lines filled. The glycol mixture should be checked periodically (3 to 6 months) for proper concentrations. When

filling the system, always use a pre-mixed solution in the proper ratio to maintain freeze and corrosion protection. Distilled water

is recommended because many municipal water supplies contain large amounts of chlorine, which can react unfavorably with

glycol.

NOTE: If supply and return lines are overhead, the fluid in the piping may drain back and overflow the chiller reservoir

if the chiller is shut down. This can be prevented by using a check valve in the supply line, and either a solenoid valve

on the return line.

Picture 5

Transformer set at 400V

Picture 6

Transformer set at 460V

English

11

Corrosion protection:

PFANNENBERG recommends that Glycol is also used as a rust inhibitor. The minimum percentage of glycol (in a mixture with

water) recommended by some important glycol supplier (Clariant, Total, Dowfrost, etc..) is between 20% and 30%.

CAUTION: Please contact the glycol supplier to know the minimum percentage needed in order to use

the glycol as rust inhibitor

CAUTION: All the typelabel of the STD Pfannenberg unit are provided with a percentage of glycol of

20%

The percentages of glycol into the mixture is related to the minimum working temperature of the mixture (that must be in line

with the minimum working set point of the unit, please see the technical data of the unit):

Propylene glycol

dilution

Working range temperature

Freezing point

%

Min [°C]

Max [°C]

PP20P

20

+10

+101

-8

PP30P

30

0

+103

-14

PP50P

54

-25

+104

-38

Ethylene glycol

dilution

Working range temperature

Freezing point

%

Min [°C]

Max [°C]

PP20E

20

+10

+102

-8

PP30E

30

0

+103

-15

PP50E

50

-25

+108

-38

CAUTION: The higher the concentration of glycol the lower the amount of heat rejection you will be

able to get out of the fluid.

CAUTION: The type of glycol (propylene or ethylene) must be in conformity with the Standard

requested by the application, please contact the Glycol supplier

.

8.1 Waterquality

To keep the hydraulic circuit correct and trouble-free, it is necessary, to check the water quality and if necessary, carry out water

treatment. The standard circuit of a water chiller is a half open system, that means, part of the water steams/evaporates out

during operation. That means, that the concentration of chloride is getting higher and the system water will cause corrosion on

the installed components.

English

12

When using water, please consider the following:

Do not use deionized water.

Do not allow mechanical contamination to get in the water. Use water filters if this could be a problem.

Water hardness should not be too high. (see below)

Watch for chemical contamination. If this is to become a problem, treat the water with passivators and/or inhibitors.

Do not allow biological, slime bacteria, and algae contamination. If this does happen, treat the water with biocides.

PFANNENBERG recommends that the properties of the water has to be checked in order to identify the quality

Water quality A (No water treatment necessary):

Fresh water from the tap, free of contamination

Ph-level:7-9

Hardness:<5°dH

Conduction:<50µS/cm

Chlorine:<20 mg/l

Water quality B (Water treatment is recommended):

Fresh water from tap, free of contamination

Ph-level:7-8, 5

Hardness:<10°dH

Conduction:<300µS/cm

Chlorine:<50 mg/l

Water quality C (Water treatment manditory):

Fresh water from tap, free of contamination

Ph-level:7-8,5

Hardness:<20°dH

Conduction:<500µS/cm

Chlorine:<100 mg/l

9. Process Oil / Fluids

PFANNENBERG chillers (in the std oil version) are designed to work with the following oil viscosity:

Fluids and oil’s with viscosity ranging between ISO VG10 and ISO VG32 (*)

NOTE: Please contact Pfannenberg Group if your oil is outside to the standard range

English

13

CAUTION: do not utilize oils with sulphur-base additives; the copper-made exchanger could be

damaged (*)

CAUTION: a suitable filtering system, for the oil to be cooled, has to be adopted, with filtration degree

ranging from 60 to 90 µm (*).

NB (*) should any doubt arise, consult PFANNENBERG Technical Office.

OIL CHILLER w/o pump

Usually, the pumpless CHILLERS are inserted in a circuit already provided with pump. Refer to instructions provided by the

system manufacturer and check that the flow rate and pressure entering the REFRIGERATOR are compatible with the values

set down in the chapter of technical data

OIL CHILLER with pump

Usually, the CHILLERS with pump are utilized to cool an hydraulic system provided with reservoir; therefore, the filling is directly

carried out on the machine. Refer to the instructions provided by the system manufacturer

OIL Chiller Start-up

For Oil chiller is stricltly recommended:

-Contamination level of system fluid should not exceed class 18/15 ( ISO 4406 )

-to follow stricktly the operating range of pressure and temperature recomended

10.Ambient temperature

When ambient temperatures are above +40 °C (+45°C / 50°C, depending on the model) or below +15 °C, PFANNENBERG

should be consulted. High ambient temperatures reduce Chiller capacity. Low ambient temperatures require special controls.

Special conditions apply when temperatures drop below 0 °C (32 °F). Fluid heaters may be required to prevent freezing and to

hold the fluid in the Chiller reservoir at a constant temperature in order to reduce start-up delays while the fluid warms up to

operating temperature.

11.Start up of the chiller

CAUTION: WORK ON THE ELECTRICAL AND REFRIGERANT CIRCUITS MAY ONLY BE PERFORMED BY

QUALIFIED PERSONEL.!!!!!!!

NOTE: The following instruction will guide you through the start up procedure in detailed steps. For a

quick commissioning instruction please see appendix A1 or A2.

NOTE: For PWW unit start up please follow the Appendix A2 and Appendix C (except verification for

phase check of 3-phase models, which is described in this paragraph).

Please consider that secondary circuit is a close loop system which has the pump installed inside to the

unit. Primary circuit is an open loop, and the pump has to be installed from customer outside to the unit.

English

14

Turn main switch, control switch, all circuit breakers to switches to the - 0 - (off) position.

Check the internal hydraulical connection (clamps and fittings) that may get loose during transportation. The removable

panels of the units are the 2 lateral panels, which are fixed with captive screws.

Picture 9 –Lateral panel

It is of utmost importance to wash the Hydraulic Circuit before commissioning the complete Cooling System. Perform the

Cleaning Procedure, before continuing Start-Up phase: wash the system with FUCHS “ Maintain professional washer LI”

(Pfannenberg part number: 46783000135 –25kg Tank) at least for 10 minutes.

Diluition Percentace:

2% Professional Washer

98%Water

(it is recommended to use demineralized water)

CHILLER with tank: Remove cap of filling connection located at the top side of the chiller (external) or reservoir top plate

(internal).

Picture 7 –Main switch

OFF

Picture 8 –Circuit breakers

OFF

Picture 10 –Filling point

English

15

Fill reservoir with water-glycol mixture until the maximum level is reached. (water quality and treatment should be

established according to the application specifications)

Connect water inlet and outlet pipes and make a visual inspection.

Establish main power feed and alarm cable with customer’s equipment.

CHILLER with pump: Purge pumps by loosening purging screw that is located on the side of pump. Be advised that the

pump has been purged correctly when only water is visible.

Picture 11 / 12 –Filling process and max level

Picture 13 –Pipe connection

Picture 14 –Electrical connections

Picture 15 –Pump purging

English

16

CHILLER with pump: Main power switch and circuit breaker for the pump (pumps) should be switched to the on position. (all

other circuit breakers should stay in the off position)

CHILLER with pump: Main switch should be switched to the - l - (on) position and the pump (pumps) should be checked for

the correct rotation. (Please note that there is an arrow located at the back part of the pump for direction indication).

Reverse two phases R-S-T on the terminal board in case of incorrect rotation

CAUTION: The pump must not flat running or in inverse direction; therefore the checking of the correct rotation

must be quick

After the water circuit has run for approx. 5 minutes, switch off the main switch and check again the visual level of the tank;

refill the tank in case of need. At this time a visual inspection of the hydraulical circuit and all connections for leaks should

be made.

Picture 16 –Pump breaker ON

Picture 17 –Main switch ON

Picture 18 / 19 –Tank top up

English

17

Switch all circuit breakers to the “on” position.

Fan should be checked for the correct rotation. (Please note that there is an arrow located at the side part of the fan-shroud

for direction indication). Reverse two phases R-S-T on the terminal board in case of incorrect rotation.

NOTE: for units without fan please verify the correct rotation on the pump motor.

At this time the Chiller should operate automatically according to the controllers “set point values”. If necessary, set controller

according to customers temperature requirements. (Please refer to the manual of the thermostat delivered with the unit).

NOTE: The unit works correctly only if the cover panels are mounted on the unit, so if for some

reason during the installation of the Chiller they have been removed, please replace them

before switching on the unit.

After installation, the REFRIGERATOR does not need intervention by the Qualified Operator.

Every calibration operation on thermostats, pressure switch and whatever component of the refrigerating circuit, the personnel

of the Technical Servicing or the Refrigerator Technician only is competent.

For further information on chiller installation, start-up or troubleshooting please contact PFANNENBERG

Picture 20 –All circuit breakers ON

Picture 21 –Fan rotating direction

English

18

Debug Table

The information described below are useful for the service staff. The faults that require the intervention of a refrigeration

engineer must be carried out only by specialized staff. Follow all electrical legislation when working on the unit based on valid

laws of the countries were the unit is placed.

Chiller

Problem

Cause

Possible corrective Action

The unit does not start

up

No supply voltage

Check the supply main voltage line

Not working thermostat

Inspect the connection, check and correct the parameter settings and if there

is no fault, replace the thermostat,

The compressor protector (KLIXON)

has switched off

Important: After the shut down of the compressor, the resetting time will

depending on the environment of the compressor: In a hot closed

environment it will be 2 hours, in ventilated 1 hour.

Note: The compressors are protected against high temperatures and

currents, with of an internal or external device (Klixon). The internal/external

device protects the compressor against the following situations:

overheating due to an inadequate cooling of the compressor motor.

Blocked compressor due to a high temperature of the motor or a high

current.

Loose connections which may cause high currents

It works, but does not

cool

There is not enough gas in the

equipment

Service by a refrigeration engineer

Faulty thermostatic valve

Service by a refrigeration engineer

Too high heat load

Possible wrong application, to be checked with our staff

Refrigerant Cycle is not working

Problem

Cause

Possible corrective Action

Switching of low

pressure switch

The unit works for short periods, it

stops and starts again after a while.

The causes are:

Low gas level in the equipment

Outlet line of the compressor is

blocked and more in detail:

satured dehydrating filter,

blocked thermostatic valve.

Service by a refrigeration engineer

Switching of the high

pressure switch

The unit does not work.

The causes are:

Dirty condenser

Clean the condenser with compressed air if it is full of dust, or use proper

solvents suitable to remove sludges.

English

19

The fan is broken

Replace the fan

Too high ambient

temperature

Check that the chiller is located in a place that can guarantee suitable

ventilation of the refrigerating unit. Check also that the ambient temperature

does not exceed +40°C.

Note: after solving the cause of

the fault, start the chiller by

pressing the reset button located

on the external body of the

pressure switch itself (see the

picture)

Compressor

Problem

Cause

Possible corrective Action

The compressor works continuously and the chiller can’t control the liquid temperature:

-too low temperature of the liquid

-too high temperature of the liquid

Too low temperature

Broken thermostat (contact blocked)

Replace the thermostat

Too high temperature

Broken thermostat

Replace the thermostat

Not enough Freon in the unit

Please ask for the service by a refrigeration engineer

Too high heat load

Possible wrong application, to be checked with our staff

Pump

Problem

Cause

Possible corrective Action

No flow rate in the circuit

Pump is down

Check the right rotation of the electrical motor

English

20

APPENDIX A1

This manual suits for next models

17

Table of contents

Languages:

Popular Water Dispenser manuals by other brands

Kripsol

Kripsol BT Series user manual

Kenmore

Kenmore ULTRASOFT 250 625.38826 owner's manual

Vertex

Vertex PureWaterCooler PWC-400 Service manual

California Faucets

California Faucets 9628SS installation instructions

Drop

Drop Pro Water Softener installation manual

GE

GE GXSF40H Owner's Manual & Installation Instructions

Harvia

Harvia AUTODOSE Instructions for installation and use

Igloo

Igloo MWC497 Specification sheet

Parker

Parker Hyperchill ICE310 user manual

Water Depot

Water Depot PLATINUM SERIES owner's manual

Kemper

Kemper 610 01 Maintenance Instruction

elysator

elysator PUROTAP Compenso Series Installation Function Operation Service