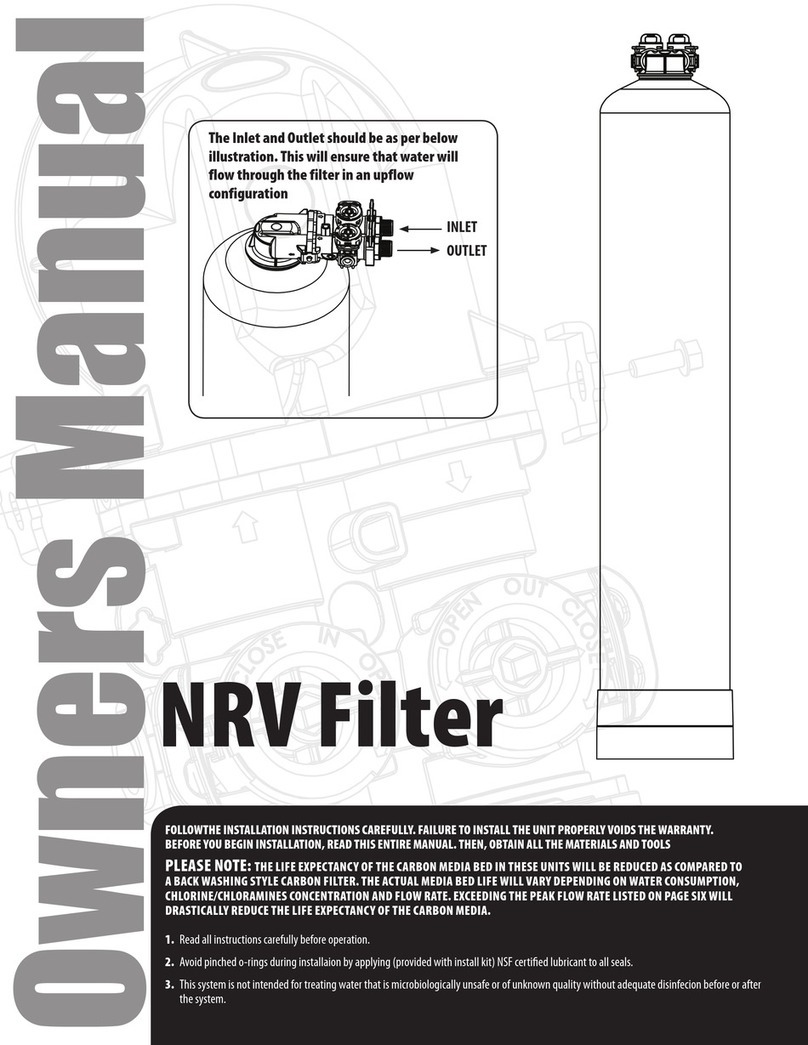

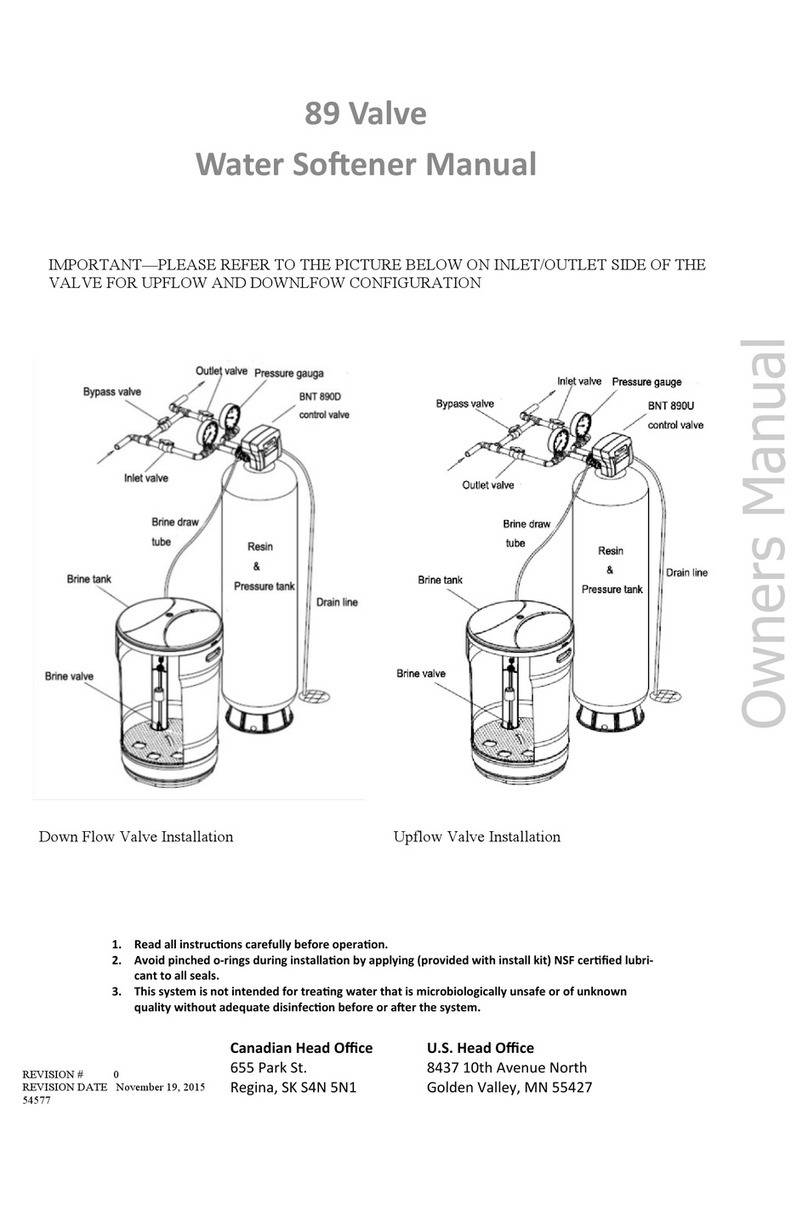

Inlet Outet

Outlet Intlet

Upflow Valve Downflow Valve

Resin

Support Bed

Gravel

O-ring

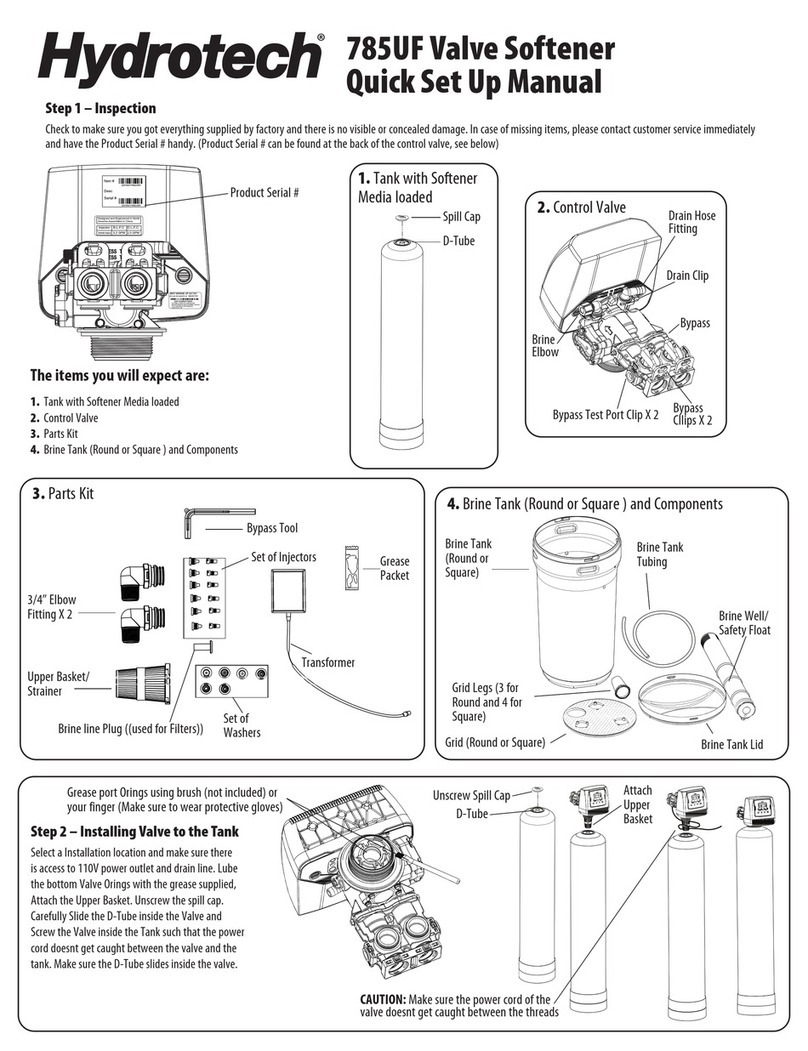

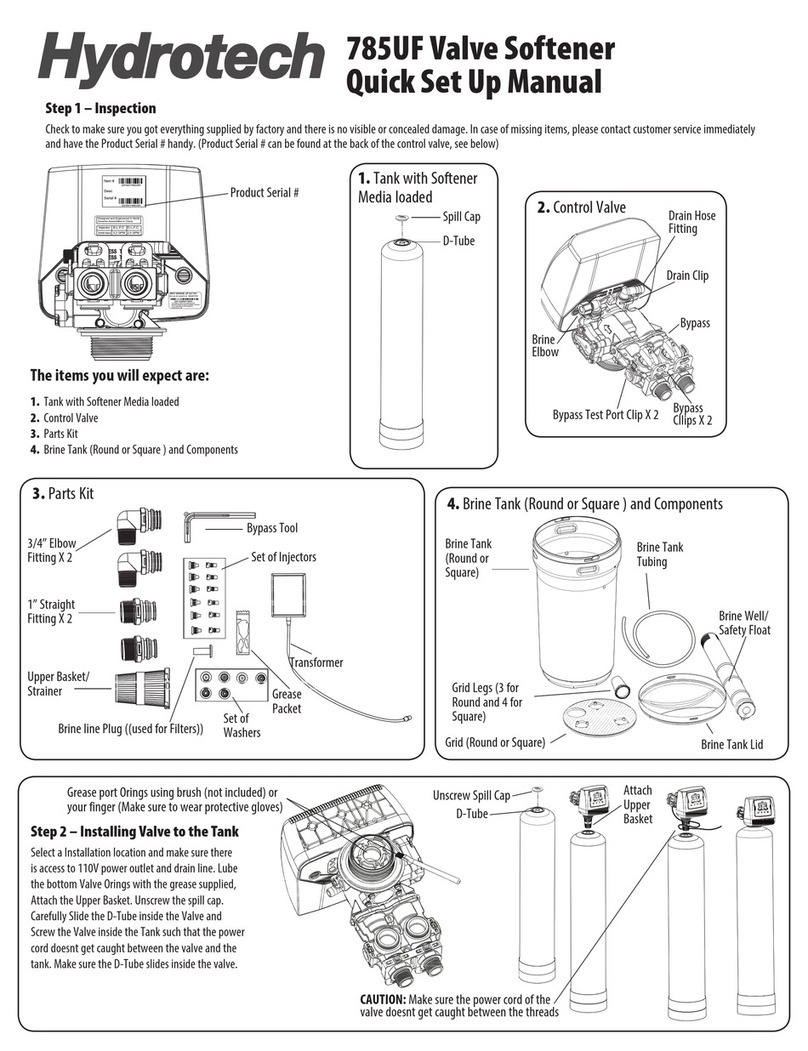

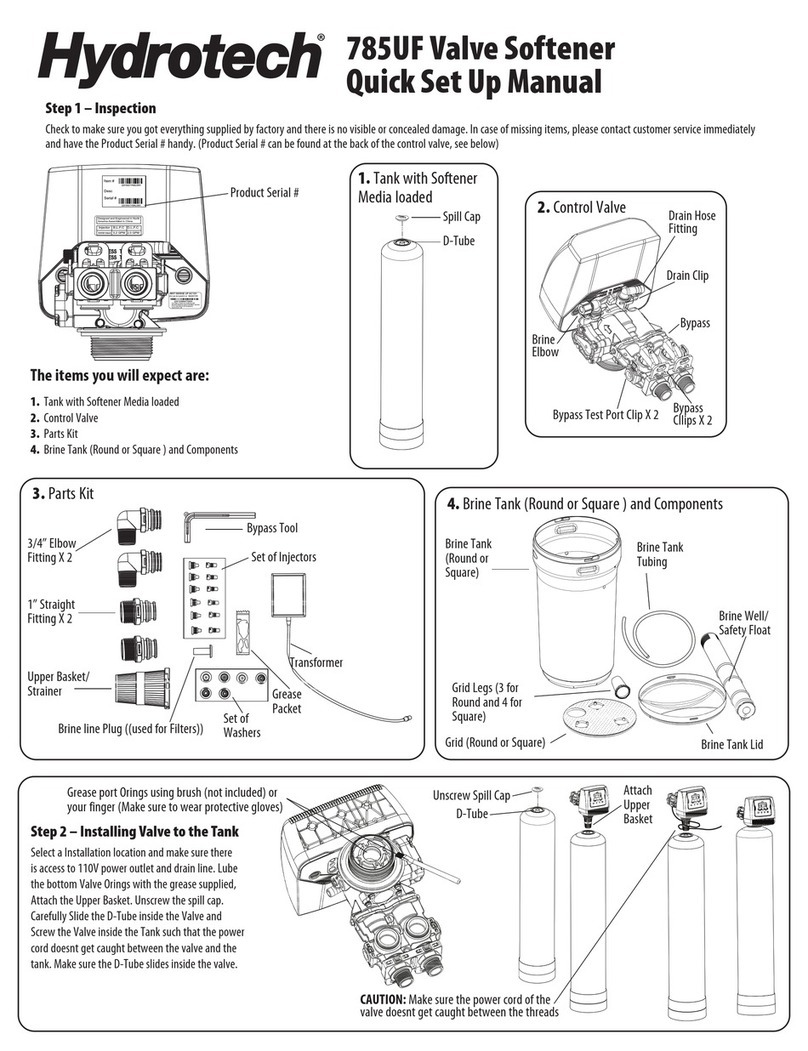

1. Media Installation

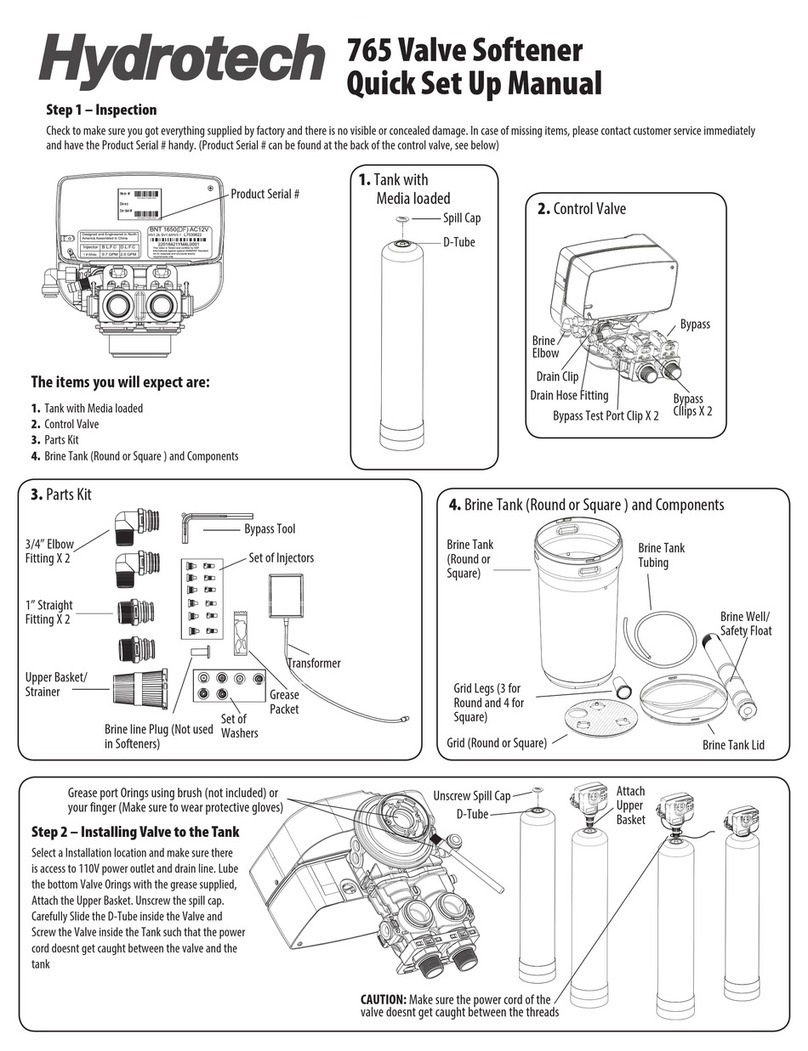

CAUTION: Make sure the power cord of the valve

doesnt get caught between the threads

Grease port Orings using brush

(not included) or your finger

(Make sure to wear protective

gloves)

Attach

Upper

Basket

1

2

3

Clips

Bypass

Unscrew Spill Cap

D-Tube

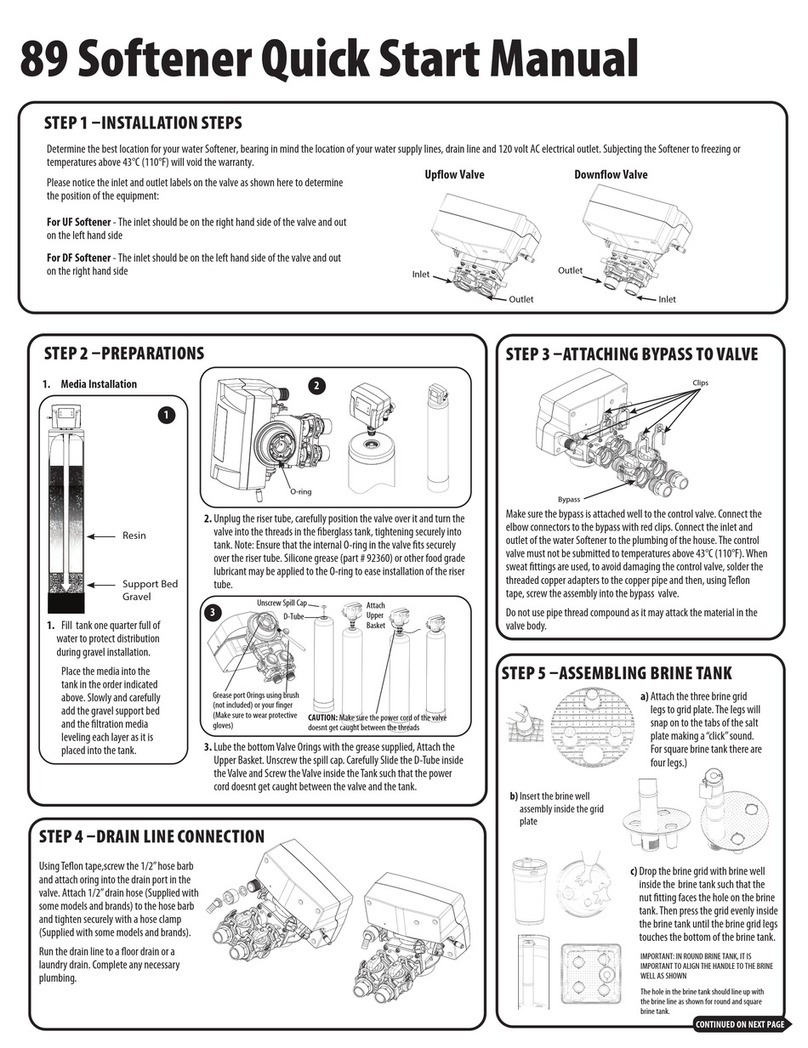

89 Softener Quick Start Manual

STEP 1 –INSTALLATION STEPS

Determine the best location for your water Softener, bearing in mind the location of your water supply lines, drain line and 120 volt AC electrical outlet. Subjecting the Softener to freezing or

temperatures above 43°C (110°F) will void the warranty.

Please notice the inlet and outlet labels on the valve as shown here to determine

the position of the equipment:

For UF Softener - The inlet should be on the right hand side of the valve and out

on the left hand side

For DF Softener - The inlet should be on the left hand side of the valve and out

on the right hand side

STEP 2 –PREPARATIONS

1. Fill tank one quarter full of

water to protect distribution

during gravel installation.

Place the media into the

tank in the order indicated

above. Slowly and carefully

add the gravel support bed

and the ltration media

leveling each layer as it is

placed into the tank.

2. Unplug the riser tube, carefully position the valve over it and turn the

valve into the threads in the berglass tank, tightening securely into

tank. Note: Ensure that the internal O-ring in the valve ts securely

over the riser tube. Silicone grease (part # 92360) or other food grade

lubricant may be applied to the O-ring to ease installation of the riser

tube.

3. Lube the bottomValve Orings with the grease supplied, Attach the

Upper Basket. Unscrew the spill cap. Carefully Slide the D-Tube inside

the Valve and Screw theValve inside the Tank such that the power

cord doesnt get caught between the valve and the tank.

STEP 3 –ATTACHING BYPASS TO VALVE

Make sure the bypass is attached well to the control valve. Connect the

straight or elbow connectors to the bypass with red clips. Connect the

inlet and outlet of the water Softener to the plumbing of the house.

The control valve must not be submitted to temperatures above 43°C

(110°F). When sweat ttings are used, to avoid damaging the control

valve, solder the threaded copper adapters to the copper pipe and then,

using Teon tape, screw the assembly into the bypass valve.

Do not use pipe thread compound as it may attack the material in the

valve body.

STEP 4 –DRAIN LINE CONNECTION

UsingTeon tape,screw the 1/2”hose barb

and attach oring into the drain port in the

valve. Attach 1/2”drain hose (Supplied with

some models and brands) to the hose barb

and tighten securely with a hose clamp

(Supplied with some models and brands).

Run the drain line to a oor drain or a

laundry drain. Complete any necessary

plumbing.

STEP 5 –ASSEMBLING BRINE TANK

a) Attach the three brine grid

legs to grid plate. The legs will

snap on to the tabs of the salt

plate making a“click”sound.

For square brine tank there are

four legs.)

c) Drop the brine grid with brine well

inside the brine tank such that the

nut tting faces the hole on the brine

tank. Then press the grid evenly inside

the brine tank until the brine grid legs

touches the bottom of the brine tank.

b) Insert the brine well

assembly inside the grid

plate

IMPORTANT: IN ROUND BRINE TANK, IT IS

IMPORTANT TO ALIGN THE HANDLE TO THE BRINE

WELL AS SHOWN

The hole in the brine tank should line up with

the brine line as shown for round and square

brine tank.

CONTINUED ON NEXT PAGE