Pfeiffer Vacuum PM 041 937-T User manual

Betriebsanleitung • Operating Instructions

Relay box for backing pumps

PM 041 937-T

PM 041 938-T

PT 0030 BE/D (0604)

2

Table of contents

Table of contents

1 About this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Validity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Proper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Improper use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Relay box single-phase, PM 041 937 -T. . . . . . . . . . . . . . . . . . . . . . 5

3.2 Relay box single-phase, PM 041 938 -T. . . . . . . . . . . . . . . . . . . . . . 5

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 Internal connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Connection to the electronic drive unit . . . . . . . . . . . . . . . . . . . . . . . 8

5 Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

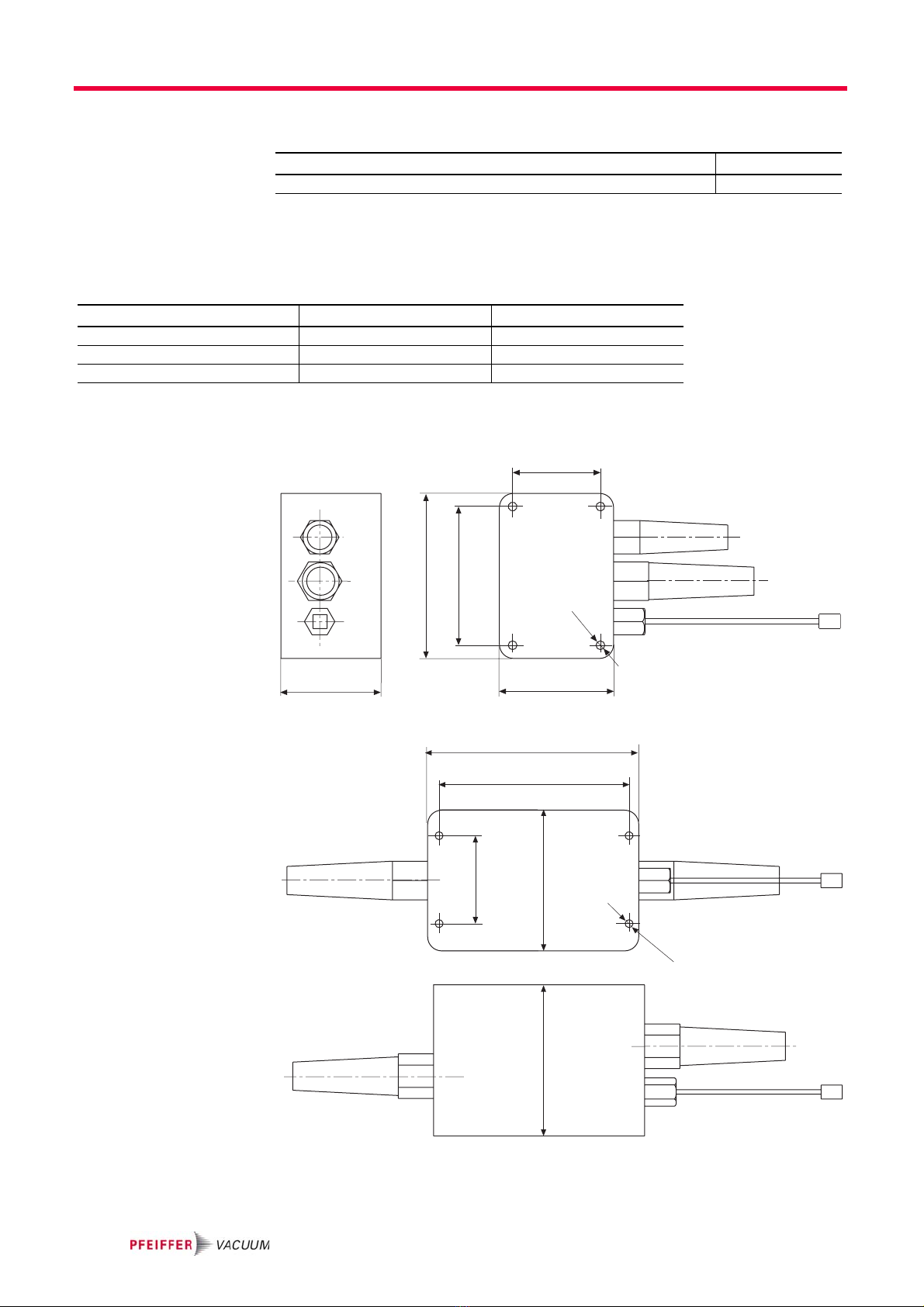

6.1 Dimension diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Declaration of conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3

About this manual

1 About this manual

1.1 Validity

This operating manual is for customers of Pfeiffer Vacuum. It describes the func-

tioning of the designated product and provides the most important information for

safe use of the unit. The description follows applicable EU guidelines. All informa-

tion provided in this operating manual refer to the current state of the product's de-

velopment. The documentation remains valid as long as the customer does not

make any changes to the product.

Up-to-date operating instructions can also be downloaded from

www.pfeiffer-vacuum.net.

1.2 Conventions

Safety instructions The safety instructions in Pfeiffer Vacuum operating manuals are the result of risk

evaluations and hazard analyses and are oriented on international certification

standards as specified by UL, CSA, ANSI Z-535, Semi-S1, ISO 3864 and DIN 4844.

In this document, the following hazard levels and information are considered:

Piktograph

definitions

Instructions in the

text

ÎWork instruction: here you have to do something.

Symbols used Fore-vacuum flange

Vacuum flange

Exhaust flange

Electric connection

Abbreviations used TC:Electronic drive unit for turbopump

TM:Electronic drive unit for HiMag

TCP:External electronic drive unit

DANGER

Immediate danger

Death or very severe injuries occur.

NOTE

Command or note

Command to perform an action or information about properties, the disregarding of

which may result in damage to the product.

Warning of a displayed source of danger in connection

with operation of the unit or equipment.

Command to perform an action or task associated with a

source of danger, the disregarding of which may result in

serious accidents.

VV

V

4

Safety

2 Safety

2.1 Safety precautions

• Observe all safety and accident prevention regulations.

• Regularly check the proper observance off all safety measures.

• Do not loosen any plug connection during operations.

• Keep leads and cables well away from hot surfaces (> 70 °C).

• The unit has been accredited with protection class IP 65. When installing into

ambient conditions, which afford higher protection classes, the necessary

measures must be taken.

• Always ensure a safe connection to the protective earthing conductor (PE, pro-

tection class I).

• Before carrying out any work disconnect the unit and all associated installations

safely from the mains.

2.2 Proper use

• The relay box may only be used until the specified maximum contact load.

• The relay box may only be used to control vacuum backing pumps to Pfeiffer

Vacuum turbopumps with related electronic drive units.

• Permissible electronic drive units for the connection of the relay boxes are:

– integrated electronic drive unit TC 100 with TCS 010

– integrated electronic drive unit TC 600

– integrated electronic drive unit TC 750

– integrated electronic drive unit TM 3000 with connection cable PM 061 144 -X

– external electronic drive unit TCP 350 with connection cable PM 061 144 -X

2.3 Improper use

Improper use will cause all claims for liability and guarantees to be forfeited. Im-

proper use is deemed to be all use for purposes deviating from those mentioned

above, especially:

• The connection of a mains power voltage not corresponding to the rating plate

• Operation with contact loads higher than the information on the rating plate

NOTE

Duty to inform

Each person involved in the installation or operation of the unit must read and observe

the safety-related parts of these operating instuctions.

ÎThe operator is obligated to make operating personnel aware of dangers originating

from the unit or the entire system.

NOTE

CE conformity

The manufacturer's declaration becomes invalid if the operator modifies the original

product or installs additional components!

ÎFollowing installation into a plant and before commissioning, the operator must

check the entire system for compliance with the valid EU directives and reassess it

accordingly.

5

Product description

3 Product description

To correctly identify the product when communicating with Pfeiffer Vacuum, al-

ways have the information from the rating plate available.

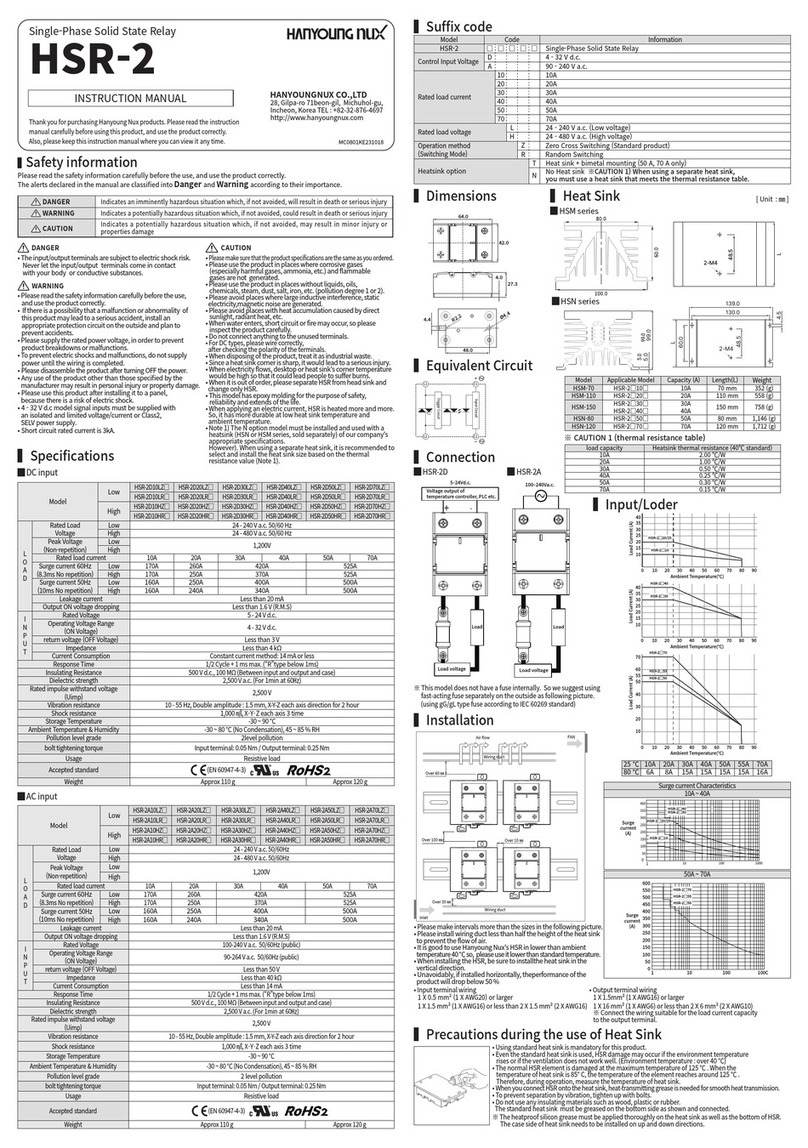

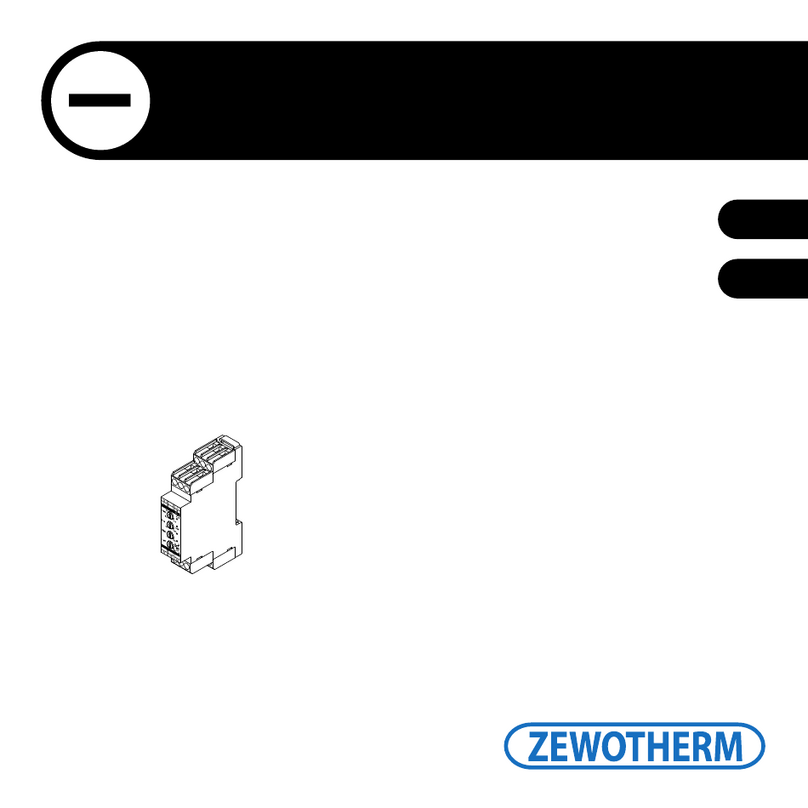

3.1 Relay box single-phase, PM 041 937 -T

Fig. 1: Relay box PM 041 937 -T

The relay box PM 041 937 -T with semiconductor relay is provided especially for

the intermittent operation on Pfeiffer Vacuum diaphragm vacuum pumps. The

maximum relay contact load is 5 A.

3.2 Relay box single-phase, PM 041 938 -T

Fig. 2: Relay box PM 041 938 -T

20 Relay box

20a Control lead

20b Connection backing pump PG 9

20c Connection mains power input PG 11

The relay box PM 041 938 -T with mechanical relay is provided for the operation of

larger Pfeiffer Vacuum backing pumps. The maximum relay contact load is 20 A.

20 Relay box

20a Control lead

20b Connection backing pump PG 9

20c Connection mains power input PG 11

20b

20a

20

20c

20b 20a20

20c

6

Installation

4 Installation

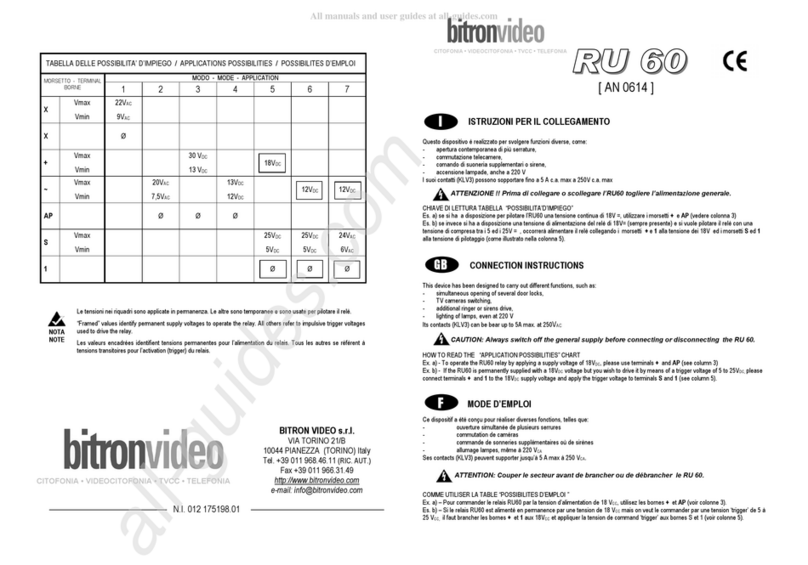

4.1 Internal connection

ÎUnscrew and remove the cover of the relay box.

ÎInstall the wiring of the mains power and the backing pump according to the fol-

lowing illustrations.

ÎClose the relay box

Fig. 3: Relay box PM 041 937 -T, internal view

Fig. 4: Relay box PM 041 938 -T, internal view

DANGER

Voltage-bearing elements

Danger to life from electric shock.

ÎThe electrical connection can be carried out only by trained and authorised electrici-

ans.

ÎEnsure the system is adequately earthed.

20a Control lead

20b Connection backing pump

20c Connection mains power input

LPENL1PE N

20b 20c 20a

LPENL1PE N

20b

20c

20a

7

Installation

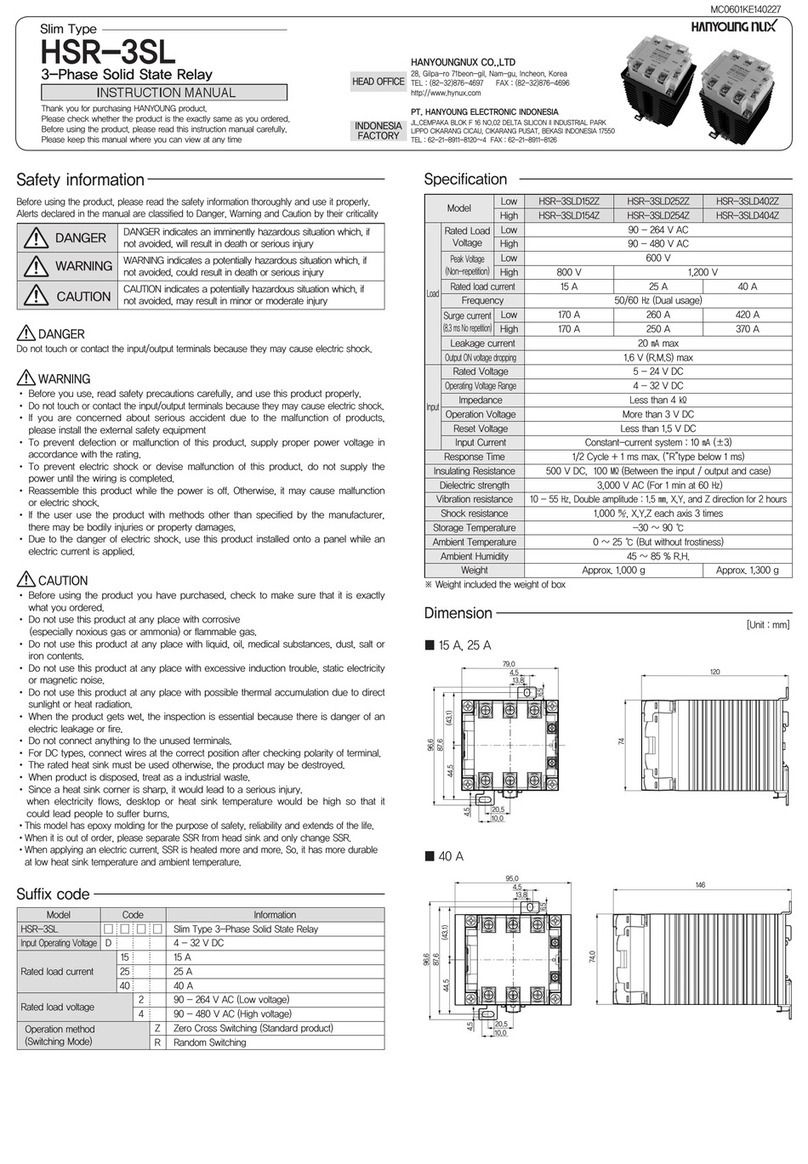

4.2 Connection diagram

Fig. 5: connection diagram PM 041 937 -T

Fig. 6: Connection diagram PM 041 938 -T

M

453621

RJ 12

Antriebselektronik /

Electronic drive unit

PE N L1

PE

F2

4 A

F1

4 A

3 x 1,5 mm2

Netzeingang /

Mains input

1

24

3

Potentialtrennung 6 mm /

Potential separation 6 mm

U1

X3.1 3 2

X1 N L

3 x 1,5 mm2

PE N L

Vorpumpe /

Backing pump

Flachleitung

4-adrig /

Flat band cable

4 core

M

PE N L1

PE

3 x 2,5 mm2

Netzeingang /

Mains input

423156

3 x 2,5 mm2

PE N L

Vorpumpe /

Backing pump

RJ 12

Antriebselektronik /

Electronic drive unit

Flachleitung 4-adrig /

Flat band cable 4 core

A1

A2

K1

N

56 7 8

9101112

K1

8

Installation

4.3 Connection to the electronic drive unit

TC 100 with TCS 010

ÎConnect the plug RJ12 of the control lead into the socket "OUT1" or "OUT2" of

the connection box TCS 010.

ÎSet up the outputs of the connection box according to the operating instructions

PM 0547 BN "Pumping operations with DCU".

ÎConnect the mains power cable of the relay box to the mains voltage.

TC 600 / TC 750

ÎConnect the plug RJ12 of the control lead into the socket "FV PUMP" on the

TC 600 or the TC 750 of the turbopump.

ÎConnect the mains power cable of the relay box to the mains voltage.

1 High vacuum flange

2 Fore-vacuum flange

8 Electronic drive unit

14 Connection box TCS 010

20 Relay box

20a Control lead

20b Connection backing pump

20c Connection mains power input

21 Vacuum backing pump

VV

1

2

14

Out1 Out2

TCS 010

TCS 010

TC 100

TC 100

8

V

21

20a

20b20c 20

100 - 240 VAC

1 High vacuum flange

2 Fore-vacuum flange

8 Electronic drive unit

20 Relay box

20a Control lead

20b Connection backing pump

20c Connection mains power input

21 Vacuum backing pump

VV

1

2

8

FV PUMP

V

21

20a

20b20c 20

100 - 240 VAC

9

Installation

TCP 350

ÎConnect the control lead of the relay box via the coupler RJ12 to the connection

cable PM 061 144 -X (accessories).

ÎPlug in the 26-pole D-Sub-plug of the connection cable into the socket "RE-

MOTE" on the TCP 350.

ÎConnect TCP and turbopump according to operating instructions PT 0092 BN.

ÎConnect the mains power cable of the relay box to the mains voltage.

TM 3000 for HiMag™

ÎConnect the control lead of the relay box via the coupler RJ12 to the connection

cable PM 061 144 -X (accessories).

ÎPlug in the 26-pole D-Sub-plug of the connection cable into the socket "REMO-

TE" on the TM 3000.

ÎConnect the mains power cable of the relay box to the mains voltage.

1 High vacuum flange

2 Fore-vacuum flange

8 Electronic drive unit

20 Relay box

20a Control lead

20b Connection backing pump

20c Connection mains power input

20d Coupler RJ 12

20e Connection cable PM 061 144 -X

21 Vacuum backing pump

VV

1

2

8

Remote

20e 20d

V

21

20a

20b20c 20

100 - 240 VAC

1 High vacuum flange

2 Fore-vacuum flange

8 Electronic drive unit and

magnetic bearing controller

20 Relay box

20a Control lead

20b Connection backing pump

20c Connection mains power input

20d Coupler RJ 12

20e Connection cable PM 061 144 -X

21 Vacuum backing pump

VV

8

1

2

Remote

20e 20d

V

21

20a

20b20c 20

100 - 240 VAC

10

Accessories

5 Accessories

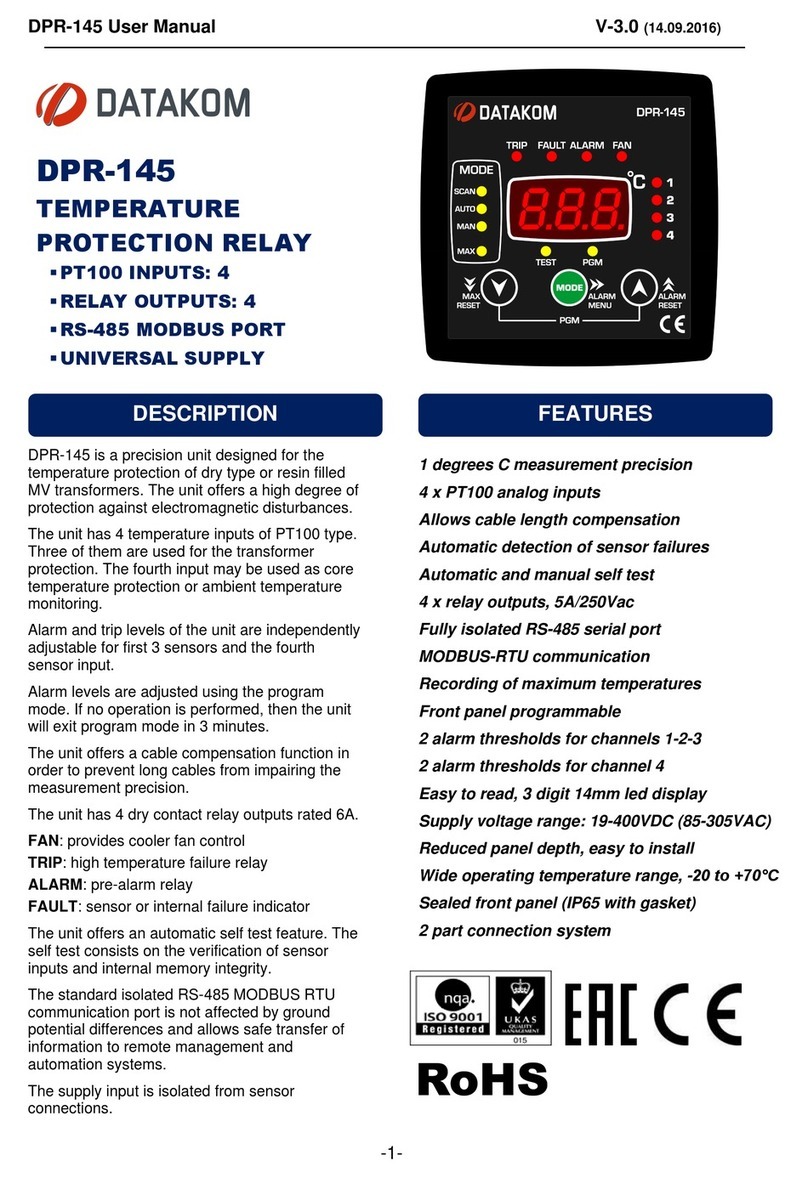

6 Technical data

6.1 Dimension diagrams

Fig. 7: Dimensions PM 041 937 -T

Fig. 8: Dimensions PM 041 938 -T

Accessories Order number

Connection cable TCP 350 / TM 3000 - backing pump relay box, length 2 m PM 061 144-X

Values Relay box 5 A Relay box 20 A

Mains connection: voltage (range) 100-240 V AC, ±10 %, 50/60 Hz 100-240 V AC, ±10 %, 50/60 Hz

Control voltage 24 V DC 24 V DC

Contact load 5 A 20 A

50

Ø5

65

94

79

57

Steuerleitung/

Control lead

PG 9

PG 11

120

108

50

86

Ø4.5

Steuerleitung/

Control lead

PG 11

PG 11

86

Declaration of conformity

pursuant to the following EU directives:

•Electromagnetic Compatibility 89/336/EEC

•Low Voltage 2006/95/EEC

We hereby certify, that the product specified below is in accordance with the pro-

vision of EU Electromagnetic Compatibility Directive 89/336/EEC and EU Low

Voltage Directive 2006/95/EEC.

PM 041 937 -T

PM 041 938 -T

Guidelines, harmonised standards, national standards in languages and specifi-

cations which have been applied:

EN 50081-1 EN 50082-2 EN 55011 EN 60742

EN 61010 IEC 801 1-4 VDE 0843-6

Signatures:

Pfeiffer Vacuum GmbH

Berliner Straße 43

35614 Asslar

Germany

(M.Bender)

Managing Director

(Dr. M. Wiemer)

Managing Director CE/2007

Pfeiffer Vacuum Technology AG · Headquarters/Germany

Tel. +49-(0) 64 41-8 02-0 · Fax +49-(0) 64 41-8 02-2 02 · info@pfeiffer-vacuum.de · www.pfeiffer-vacuum.net

Vacuum is nothing, but everything to us!

Turbopumps

Rotary vane pumps

Roots pumps

Dry compressing pumps

Leak detectors

Valves

Components and feedthroughs

Vacuum measurement

Gas analysis

System engineering

Service

This manual suits for next models

1

Table of contents

Other Pfeiffer Vacuum Relay manuals