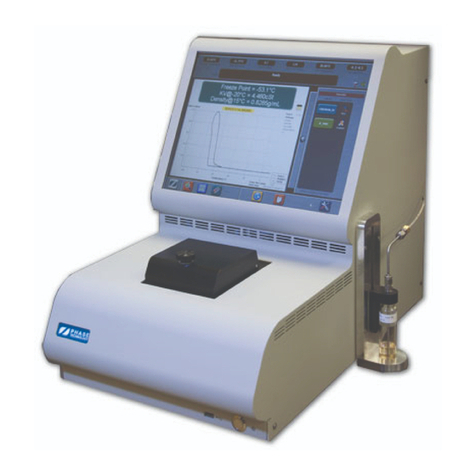

70Xi Cold Flow Properties Laboratory Analyzer User Guide

6

1. The analyzer should be set up on a flat, vibration-free surface in a well-ventilated location.

2. On the back of the analyzer, remove the red caps that cover the “PURGE IN” and “PURGE OUT”

fittings. These caps should be kept with the shipping box and related packing materials.

3. Attach the dryer bottle assembly to the back panel by fitting the two mounting bracket holes over

the two mounting screws.

4. Separate the quick-connect fittings on the dryer bottle. Press the latch on the female fitting and

pull them apart.

5. Attach the quick-connect fittings to the “PURGE IN” and “PURGE OUT” fittings on the back of the

analyzer. A “click” sound confirms that the fittings have snapped into place.

6. Mount the Sample Injection Port Assembly onto the analyzer cover with the 4 mounting screws.

Make sure the stainless steel tubing of the Sample Injection Assembly point to the back of the

analyzer. Rotate the tubing if needed. Connect the sample transfer tube (1/8” Teflon tube with

stainless fitting on one end and brass fitting on other end) from the Sample Injection Port

Assembly (stainless steel fitting) to the analyzer “SAMPLE IN” port (brass fitting). Connect the

supplied 1/8” Teflon tube (with brass fitting on one end and no fitting on other end) from the

analyzer “SAMPLE OUT” port to a user-supplied waste bottle.

7. Connect the power cable to the back of the 70Xi Analyzer. Plug the power cable into a grounded

AC outlet that is a dedicated circuit. Use a power surge protector, equipped with a line filter, if

your power source is unstable or noisy.

8. To power up the analyzer, press the round button at the bottom right hand side at the front of

the analyzer.

9. The analyzer will perform a set of self tests to verify that each of the main components of the

analyzer, including the optics system and cooling system, are operating correctly. If a problem is

detected, the self tests will stop and a message will be displayed at the bottom of the screen.

If any component fails the self tests, press the INTELLINOSTICS button for further

information and troubleshooting steps.

How to Connect and Power On

the Analyzer 1