Page 2

TABLE OF CONTENTS

Introduction ............................................................................................2

Safety Warning ........................................................................................2

Our Guarantee.........................................................................................2

Our Recommendations............................................................................3

Important Information About EPP Foam..................................................3

Lithium Polymer Battery Warnings - Please Read ..................................4

Tools and Supplies Required...................................................................5

Kit Contents.............................................................................................5

Tips From the Pros ..................................................................................6

Motor Installation .....................................................................................6

Wing Installation ...................................................................................... 8

Stabiliser Installation................................................................................9

Control Surface Hinging ........................................................................10

Control Systems Installation..................................................................13

Landing Gear Installation ......................................................................16

Final Assembly ......................................................................................17

Balance Point and Control Throws........................................................19

Pre-Flight Check and Safety..................................................................19

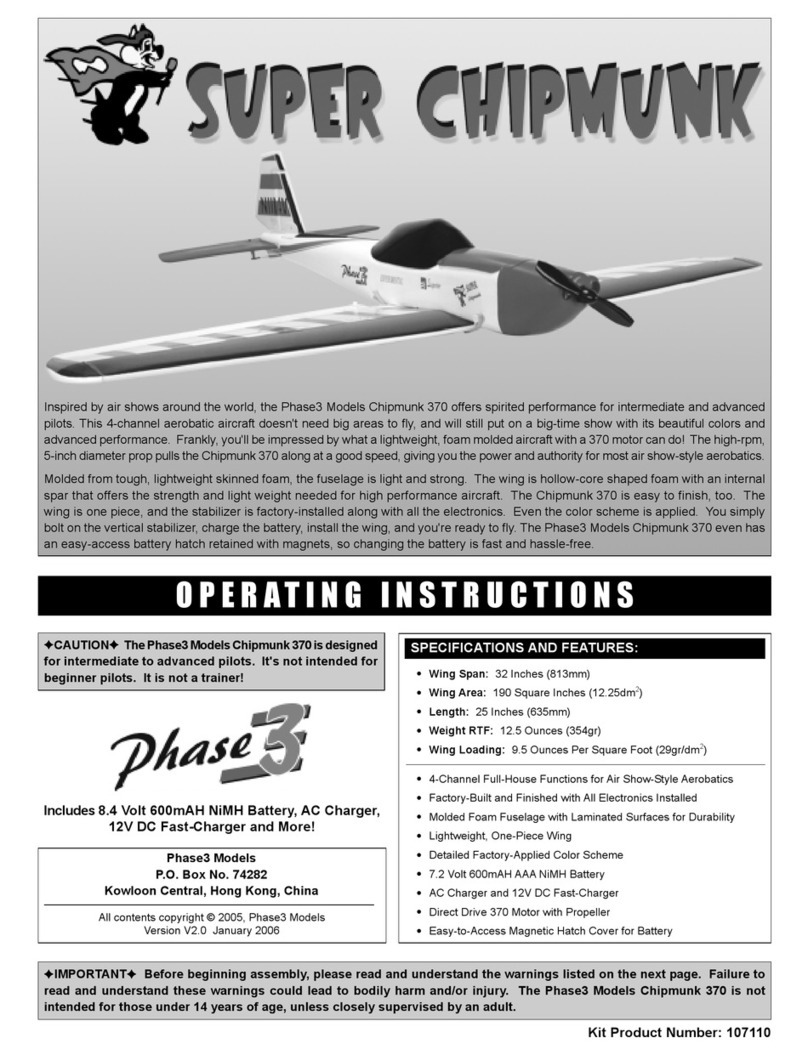

Thank you for purchasing the Phase 3 Models Quick Time 3D EP. We're condent that the quality of your new aircraft meets and

even exceeds your expectations. Before completing the nal assembly of your new aircraft, please carefully read through

these assembly instructions in their entirety. Doing so will ensure your success the rst time around!

These assembly instructions are designed to guide you through the entire assembly process of your new aircraft in the least amount

of time possible. Along the way you'll learn how to properly assemble your new aircraft and also learn tips that will help you in the

future. We have listed some of our recommendations below. Please read through them before beginning assembly.

lPlease read through each step before beginning assembly.

You should nd the layout very complete and straightforward.

Our goal is to guide you through assembly without any of the

headaches and hassles that you might expect.

lThere are check boxes next to each procedure. After you

complete a procedure, tick the box. This will help prevent you

from losing your place.

lCover your work table with brown paper or a soft cloth, both to

protect the table and to protect the parts.

lKeep a couple of small bowls or jars handy to put the small parts

in after you open the accessory bags.

lWe're all excited to get a new aircraft in the air, but take your

time. This will ensure you build a straight, strong and great ying

aircraft.

lIf you come across this symbol +, it means that this is an

important point or an assembly hint.

INTRODUCTION

This R/C aircraft is not a toy! If misused or abused, it can cause serious bodily injury and/or damage to property. Fly only in open areas

and preferably at a dedicated R/C ying site. We suggest having a qualied instructor carefully inspect your aircraft before its rst

ight. Please carefully read and follow all instructions included with this aircraft, your radio control system and any other components

purchased separately.

SAFETY WARNING

OUR GUARANTEE

Phase 3 Models guarantees this kit to be free from defects in both material and workmanship at the date of purchase. This does

not cover any component parts damaged by use, misuse or modication. In no case shall Phase 3 Models's liability exceed

the original cost of the purchased kit.

In that Phase 3 Models has no control over the nal assembly or material used for nal assembly, no liability shall be assumed for any

damage resulting from the use by the user of the nal user-assembled product. By the act of using the nal user-assembled product,

the user accepts all resulting liability.