HD7811/94

REPAIR INSTRUCTION

Descaling

Descaling is an important element in Senseo maintenance.

It should be done at least once every 3 months, up to 6 times

a Year!

This will prolong the life of your appliance and will guarantee

optimal brewing results for a long time.

Use the correct descaling agent.

Only citric acid-based descalers are suitable for descaling

the SENSEO®machine. This type of descaler descales the

appliance without damaging it. For the correct amount, see

under ‘Descaling procedure’ below. Each descaling mixture

can be used only once. After use, the descaling mixture is no

longer active.

We advise you to use the special SENSEO®Descaler

(HD7006). Read the instructions on the package of the

descaling agent.

Never use a descaling agent based on mineral acids such as

sulphuric acid, hydrochloric acid, sulphamic acid and acetic

acid (e.g. vinegar). These descaling agents may damage your

SENSEO®coffee machine.

• Follow the steps in the section headed “Descale the

appliance” see DFU (Direction for Use manual)

Volume adjustment

The PCB circuit board makes it possible to adjust the volume

output by means of pushing the one-cup and two-cup user

controls.

How to adjust the volume output:

1. Be sure the boiler is filled properly, other wise perform fill

procedure see DFU for instructions.

2. Switch appliance on and wait until the unit is ready to

brew.

3. Be sure a pod holder is placed, but without a Coffee

POD. (Only adjusting with plain water)

4. Place a cup on the drip tray cover and push the one-cup

button.

5. When the appliance has finished it is stabilized to perform

the volume adjustment.

6. Empty the cup, podholder and push again for one cup

setting, measure the volume output with a graduated

beaker. In the table you can find the requirements for

the minimum / maximum volume output cc/mL values

depending from the country version:

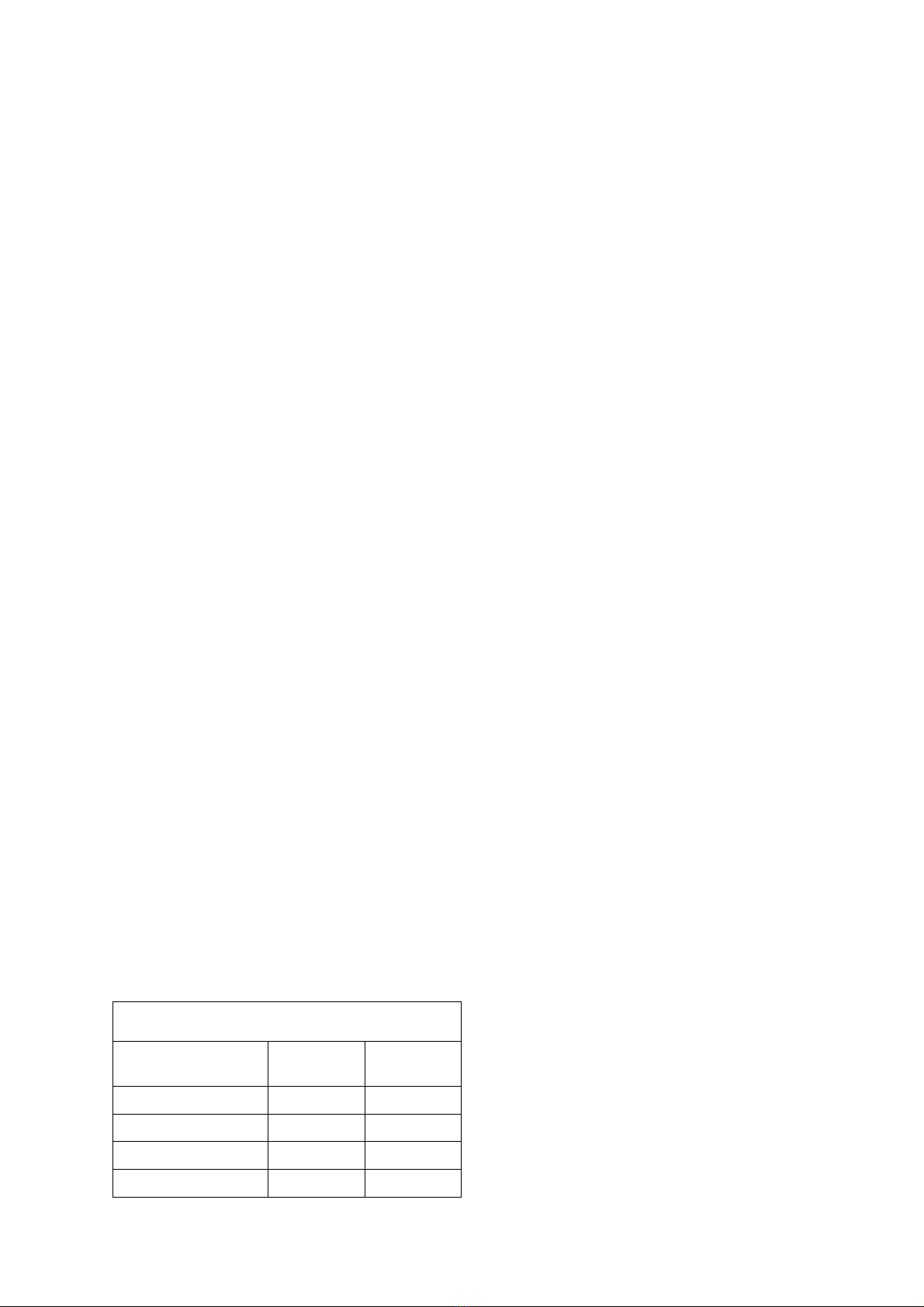

One-cup setting, Including Pod holder, water spec.

(Without Coffee pod)

Min. water

cc/mL

Max. water

cc/mL

France version 104 120

General (Europe) version 125 141

Spain version 55 71

Brazil version 65 81

7. Unplug the appliance from the mains.

8. Press the 1- and 2 cup button simultaneously and plug

the mains on.

9. When above step succeeded the led will turn on

continuously.

10. Depending if the volume has to de- or increase you have

to push the one- or two cup button.

Every time you push the 1- or 2 cup button the LED will

turn off for 0.5 second (feedback to user) and the pump

time will be shortened or lengthened for 0.5 seconds

depending which button was pushed.

Pushing 1 cup button pump, time will be shorten with

0.5 sec is approximately − 3.5 cc/mL (less coffee)

Pushing 2 cup button pump, time will be lengthen with

0.5 sec is approximately + 3.5 cc/mL (more coffee)

When the volume has to increase with 10 cc for example,

push the 2 cup button 3 times.

The new value will be stored when you switch the

appliance off by pushing the main switch.

(LED will turn off)

11. Turn appliance on again and brew one cup, measure the

volume. In case the volume is not within specification

repeat steps 6 - 11.

12. End.

Automatic filling procedure:

The Senseo PCB contains a automatic filling procedure

software routine.

This fill routine is only meant for back-up.

Normally the consumer has to follow the guidelines stated in

the DFU.

The filling procedure functions as follows:

The consumer has to fill the water container and has to plug

the appliance on the mains.

When the Senseo main switch has been pushed the main

switch LED will light continuously. This is only the case

when the Senseo has not finished the filling procedure

completely! (First use)

When the consumer pushes the one or two-cup button, the

Senseo will start automatically the pump to fill the boiler.

When the boiler is filled the pump stops pumping.

(Pump time approximately 22 seconds)

When the filling procedure has been successful the software

will clear a Boiler_empty_flag in the Eeprom.

By means of this Boiler_empty_flag the system knows the

boiler is filled or not!

When the Senseo is switched off or disconnected from the

mains, the value of the Boiler_empty_flag is stored in the

Eeprom chip.

3-6