Philips PREMIUM 10501 Operating and maintenance instructions

Other Philips Network Hardware manuals

Philips

Philips Dynalite DDPB22RJ12 User manual

Philips

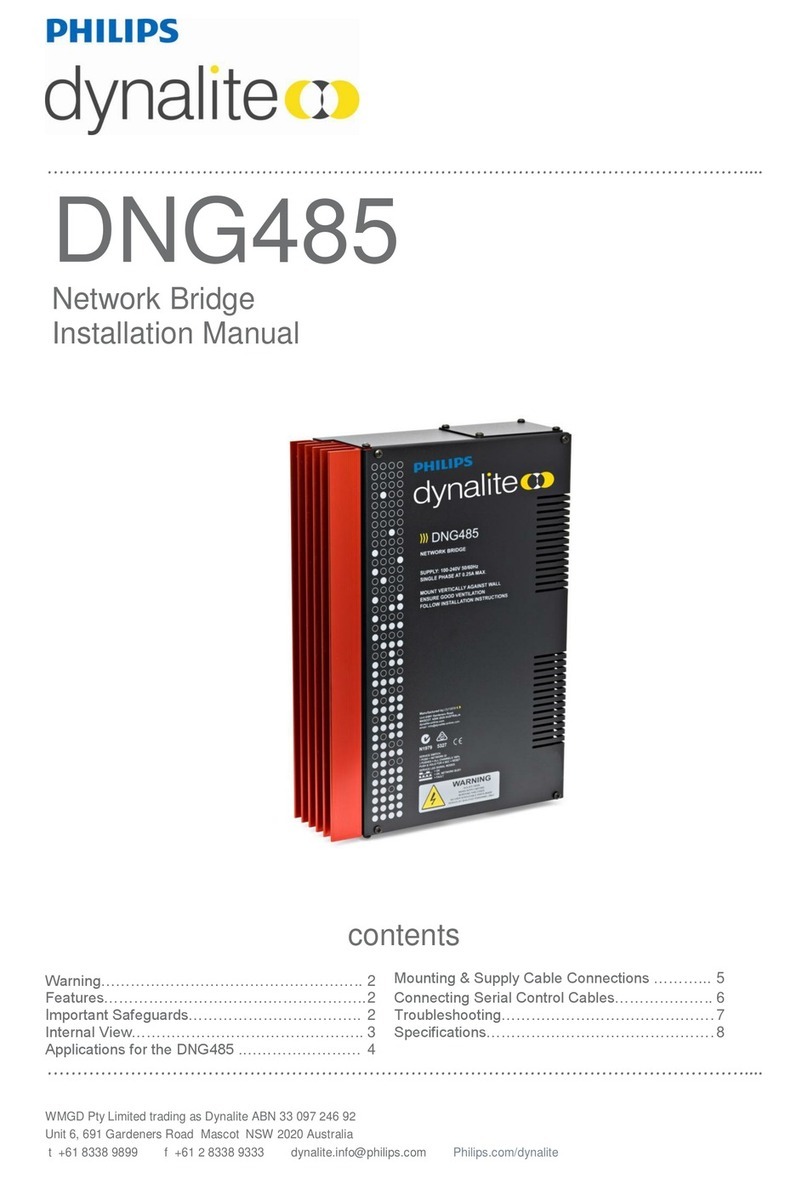

Philips dynalite DNG485 User manual

Philips

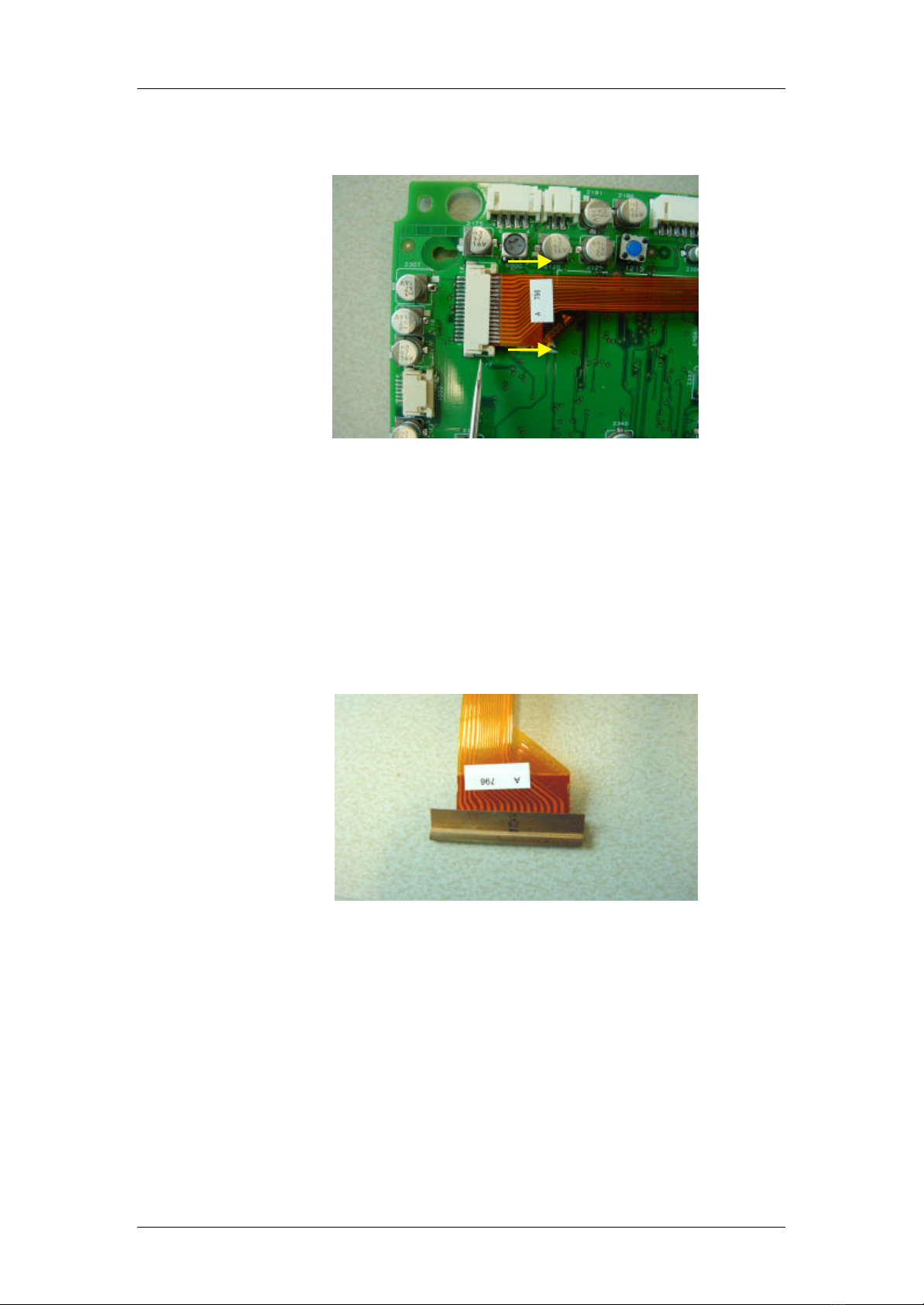

Philips TDA8783 User manual

Philips

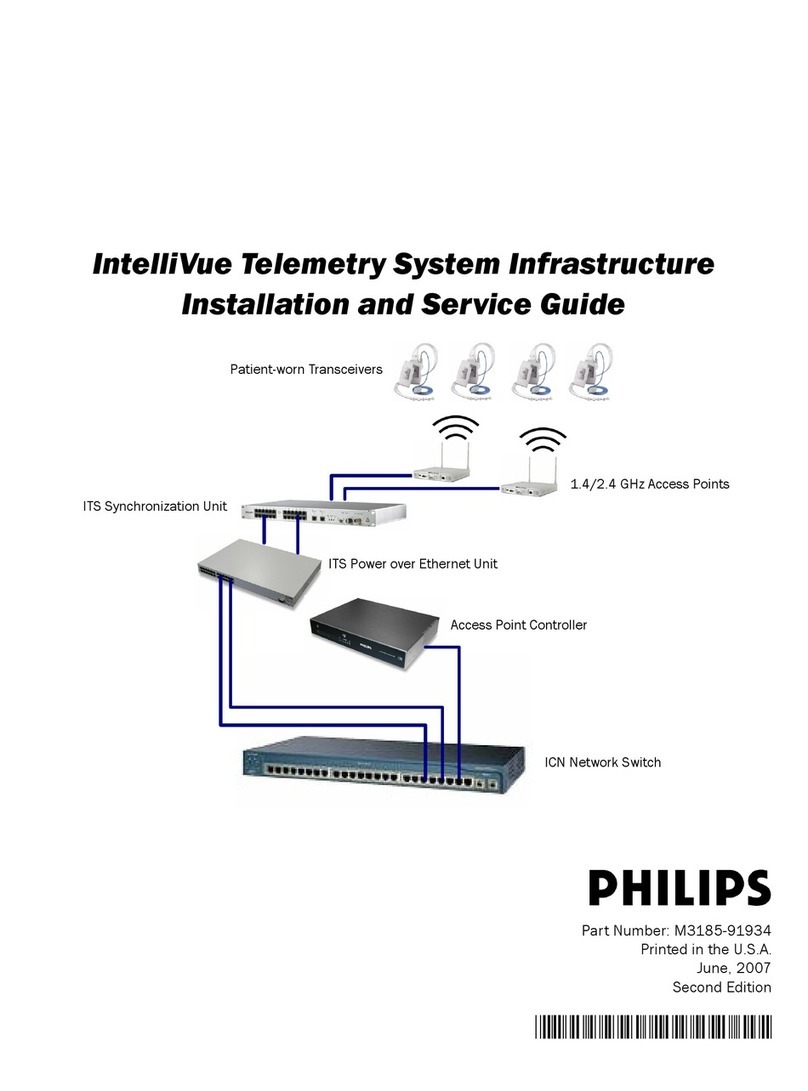

Philips IntelliVue Telemetry System Infrastructure Installation and maintenance instructions

Philips

Philips Dynalite DDPB22RJ12 User manual

Philips

Philips TDA9964 User manual

Philips

Philips PM 6302 User manual

Popular Network Hardware manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-HD161DEL product manual

B&B Electronics

B&B Electronics ZXT9-IO-222R2 product manual

Yudor

Yudor YDS-16 user manual

D-Link

D-Link ShareCenter DNS-320L datasheet

Samsung

Samsung ES1642dc Hardware user manual

Honeywell Home

Honeywell Home LTEM-PV Installation and setup guide