www.hartmann-electronic.com Rev. 1.1 3

Contents

1. Safety.....................................................................................................................................................................4

Intended Application..............................................................................................................................................4

Safety Symbols .....................................................................................................................................................4

General Safety Precautions ..................................................................................................................................4

Safety Instructions.................................................................................................................................................5

Protection Against Electromagnetic Interference (EMI).....................................................................................5

Electrostatic Discharge Precautions...................................................................................................................5

Installation ..........................................................................................................................................................5

Location..............................................................................................................................................................5

Voltage Hazards.................................................................................................................................................5

System Overheating...........................................................................................................................................5

Mounting Considerations....................................................................................................................................6

Electrical Hazards...............................................................................................................................................6

Board Installation................................................................................................................................................6

2. Product Description ...............................................................................................................................................7

Related Documentation.........................................................................................................................................7

Chassis Description...............................................................................................................................................8

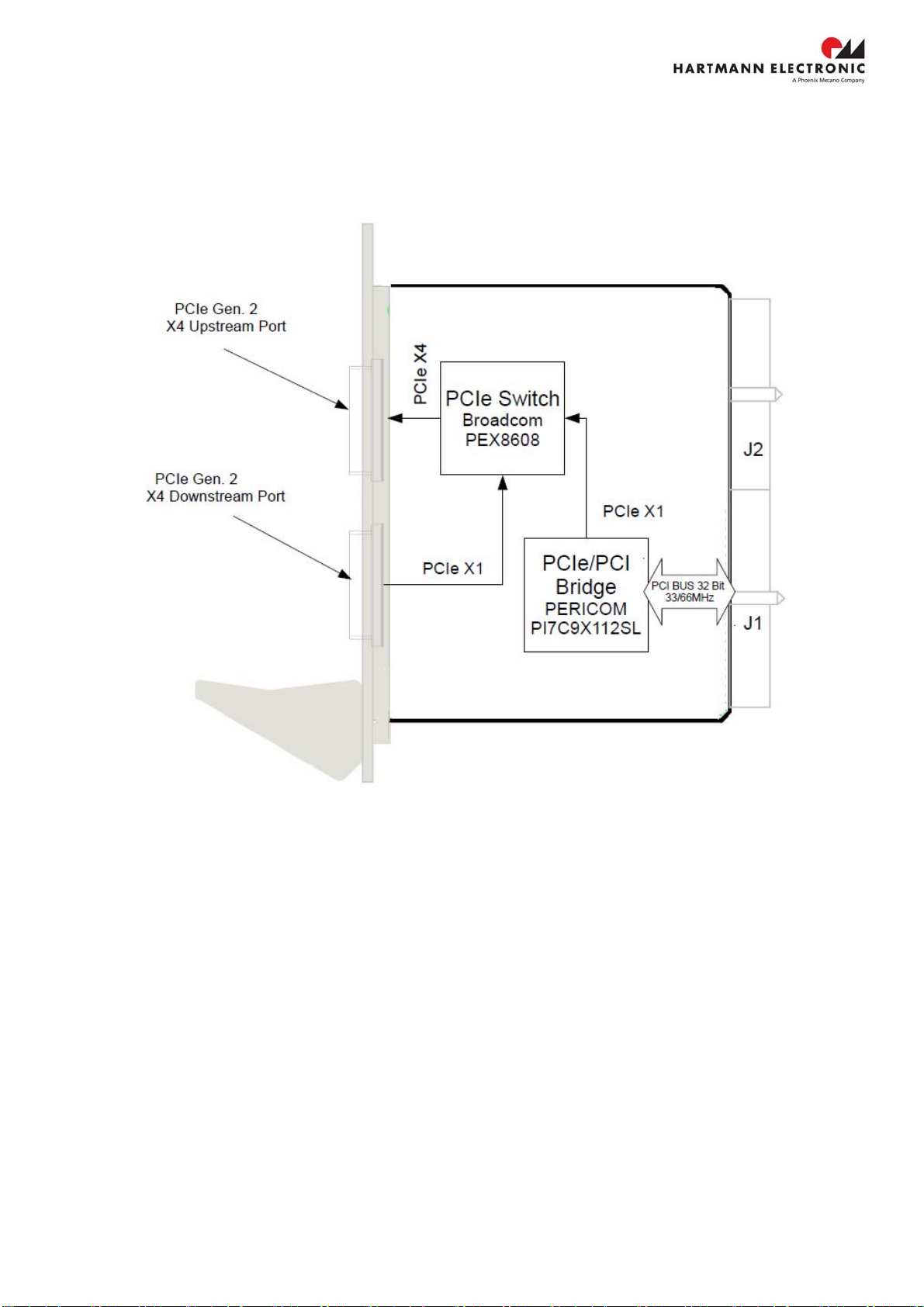

Block Diagram.......................................................................................................................................................9

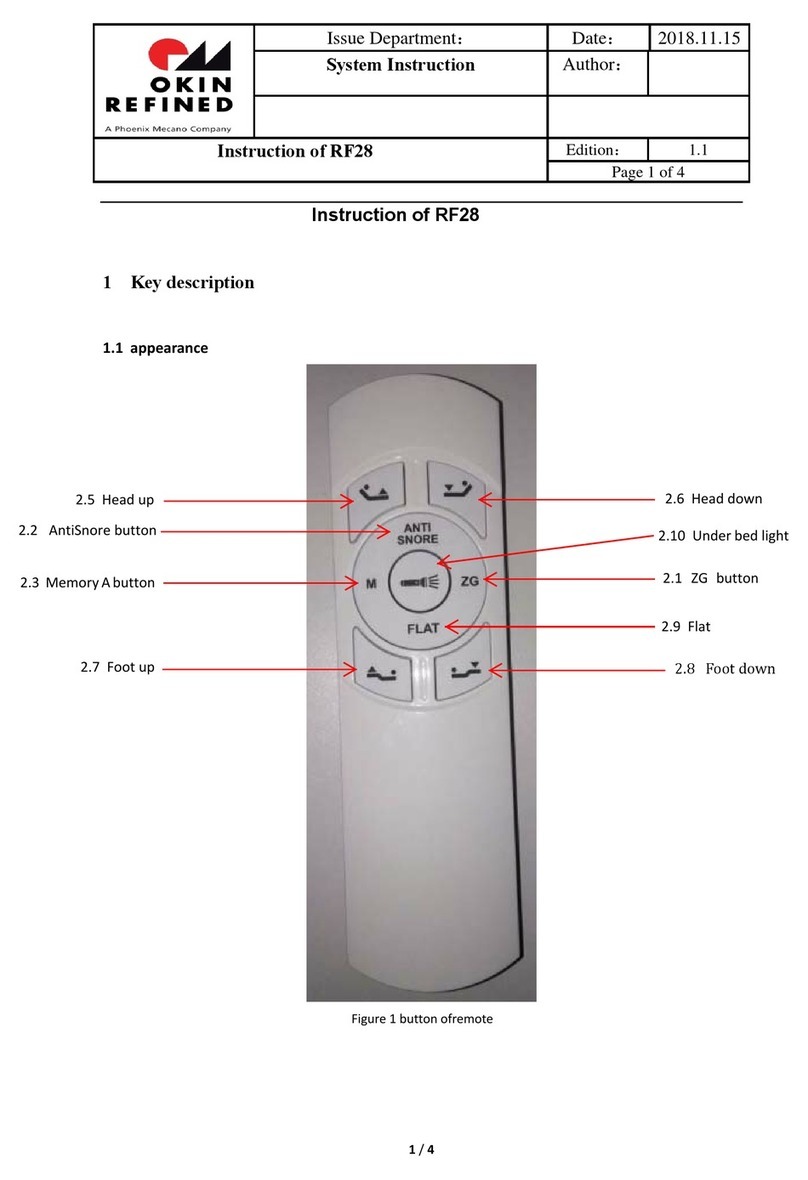

PCIE101A PCIe Gen. 3 X4 PC Card..................................................................................................................9

PXE100A PCIe Gen. 2 Uplink to CPCI ............................................................................................................10

Front Panel LEDs................................................................................................................................................11

3. Installation............................................................................................................................................................12

Installing Hardware..............................................................................................................................................12

Installing a further CPCI Remote Controller at the PCIe X4 Downstream Port..................................................14

Installing Software...............................................................................................................................................15

4. Specification ........................................................................................................................................................16

Electrical..............................................................................................................................................................16

DC Input ...........................................................................................................................................................16

Operating Environment ....................................................................................................................................16

Electromagnetic Compatibility..........................................................................................................................17

5. Pin Assignment....................................................................................................................................................19

6. Ordering Information............................................................................................................................................20