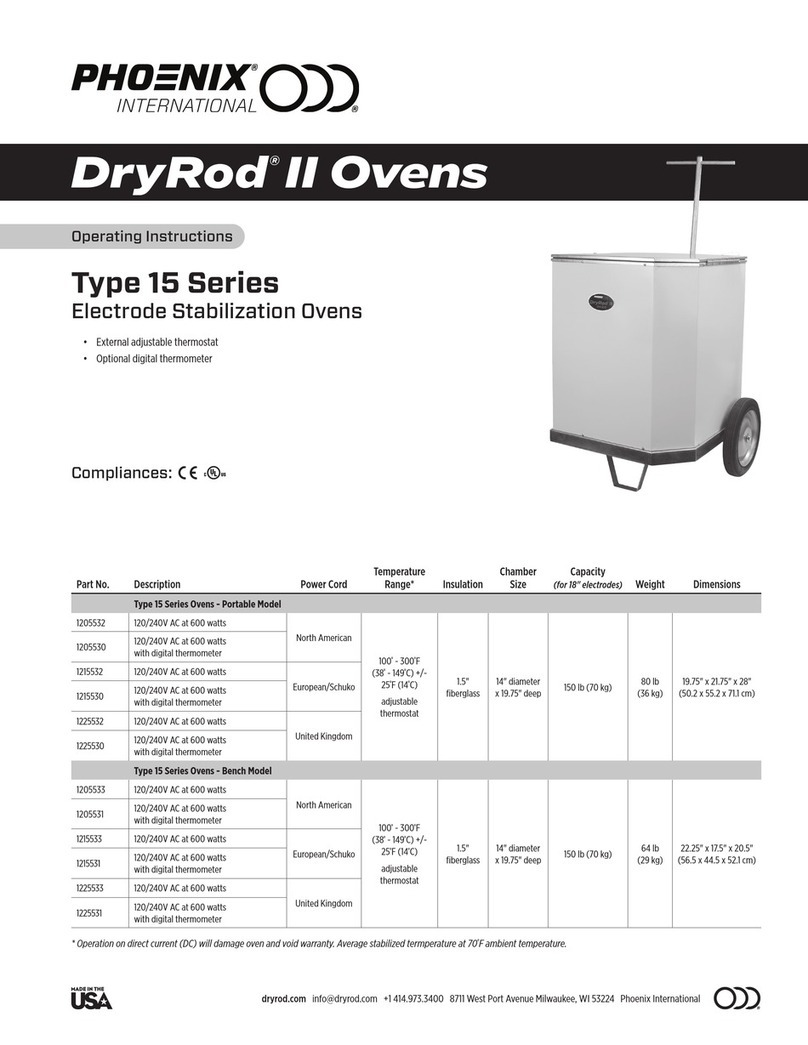

Type 40HT Series Electrode Rebaking Ovens Operating Instructions Operating Instructions

2

Phoenix

International

8711

W

est

Port

Av

enue

Milwaukee,

WI

53

224

+1

414.97

3.3400

[email protected] dryrod.comProduct Description

Installation

This oven was crated and packaged for long-distance shipment. Exercise care in

removing the oven from the wooden crate.

Lifting hooks are supplied for ease of movement into desired location.

After oven is in final location, anchor as required, open the oven door and remove

packing material, manuals and loose parts.

Wiring

Check type and voltage on nameplate.

40HT (3/480V)

40HT (1/240V)

For Wiring

1. Remove side electrical panel and remove knock-out in lower left corner.

2. Attach conduit or heavy gauge electrical cord and strain relief capable of

handling the load of the oven.

3. From incoming power supply: For 240V attach ground to green terminal

block. Attach neutral to terminal block. Attach power to terminal block. (See

wiring diagram on page 6) For 480V, attach ground to green terminal block.

Attach each phase to terminal blocks.

Make sure all wiring connections are tight. Attach side electrical panel removed in

Step 1.

Amp Draw

Ovens operating on 240 AC voltage draw 19 amps. Those operating on 480 AC

voltage draw 10 amps.

Grounding

The 40HT ovens have a grounding terminal block in the side control panel. The

oven operates with electrical components where grounding is required for safe

operation. The grounding connection should be made at the ground terminal in

the oven and should be run separately to a positive ground.

Inspection

It is essential that a general inspection of the oven be conducted at this time.

Check all components, wiring for terminal for proper tightness and door for proper

adjustment.

This unit was wired and tested at the factory and need only be connected to the

proper line voltage. It is strongly recommended that a fused safety disconnect

switch be installed in close proximity to the oven.

Operation

1. Start-up (switch in “OFF” position)

2. Turn on power to the oven.

3. Set temperature controller at desired temperature by pressing the UP/DOWN

keys and then pressing ENTER.

Power Supply

DryRod®ovens are designed to run on AC voltage and accept either 120 or 240

volts +/-10%. When power is supplied, the indicator light will illuminate.

DryRod ovens are supplied with a voltage selector switch to operate on either 120

or 240 AC voltage. Please be sure to set the switch to the proper voltage being

used. Operation outside these voltages will impact oven temperature.

Temperature Setting

Excess Heat: At maximum setting, the actual temperature in portions of the oven

near the heating elements may reach approximately 660°F (349°C). Temperatures

over 550°F (288°C) are not recommended. They may cause oven damage and/or

unacceptably high exterior surface temperatures.

Description of Controls

A. The controller in this oven is a full-indicating, PID (proportional, integral,

derivative) controller using a Type J thermocouple sensor. The controller is

factory set for optimum performance accuracy with a 400 lb load at maximum

temperature.

B. The high-limit control is a mechanical device with on-off control action. The

high-limit control will shut down the oven heat when the oven temperature reaches

the high-limit set point. In order to regain power to the heating elements, the oven

must cool down below the high-limit set temperature.

Controller

If any adjustments are required, they should be done by a qualified person with

the aid of the instructions contained in this manual or the Original Factory Setting

Guide (available upon request from Phoenix International). All instruments are

fully tested and adjusted for optimum performance prior to shipping the oven.

If the settings are lost for some reason, contact Phoenix International for the PID

Controller Original Factory Setting Guide.

Fan

A fan and filter are included to assist with cooling of electrical components and the

controller. This fan has an expected lifespan of 2-3 years depending on ambient

usage conditions. It is suggested that the fan operation is checked every six

months. If fan is not operating, replace immediately.

CAUTION

• Disconnect power and make sure oven is cooled before opening or

servicing unit.

• Hot Surfaces! Use extreme care to avoid possible burns or personal injury.

Protective gloves and personal protective equipment are recommended.