Phoenix

International

8711

W

est

Port

Av

enue

Milwaukee,

WI

5322

4

+1

414.97

3.3400

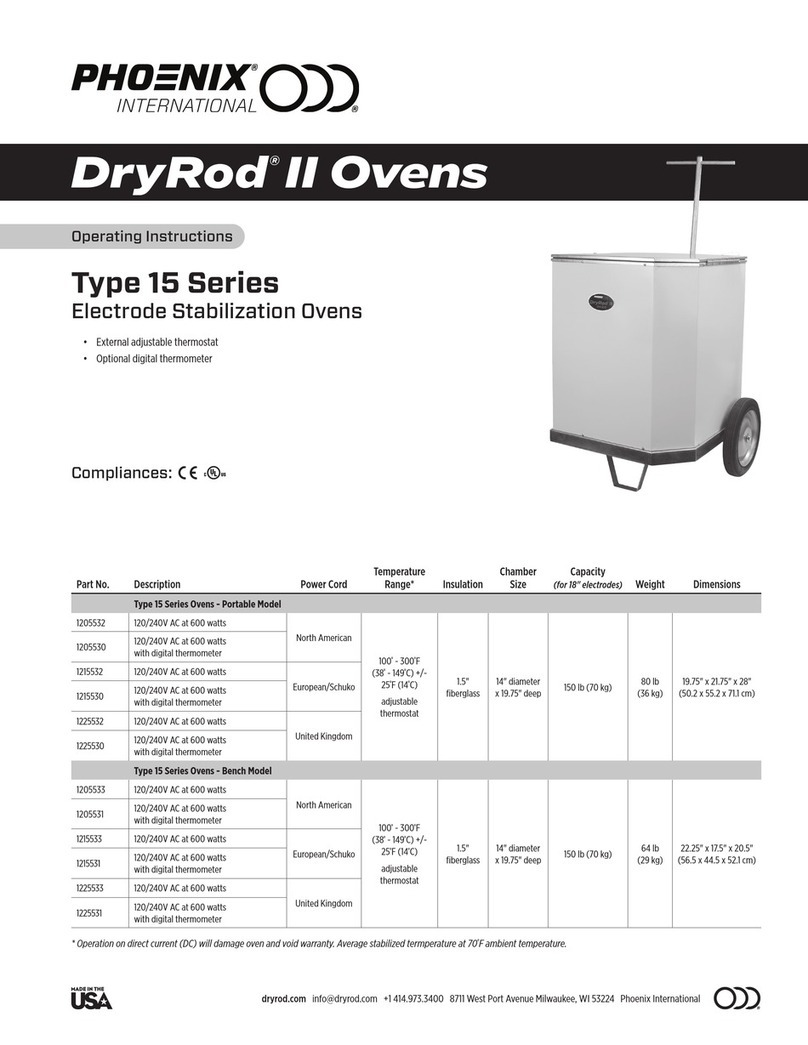

[email protected] dryrod.comType 750HT Series Flux Rebaking Ovens Operating Instructions Operating Instructions

2

Product Description

Installation

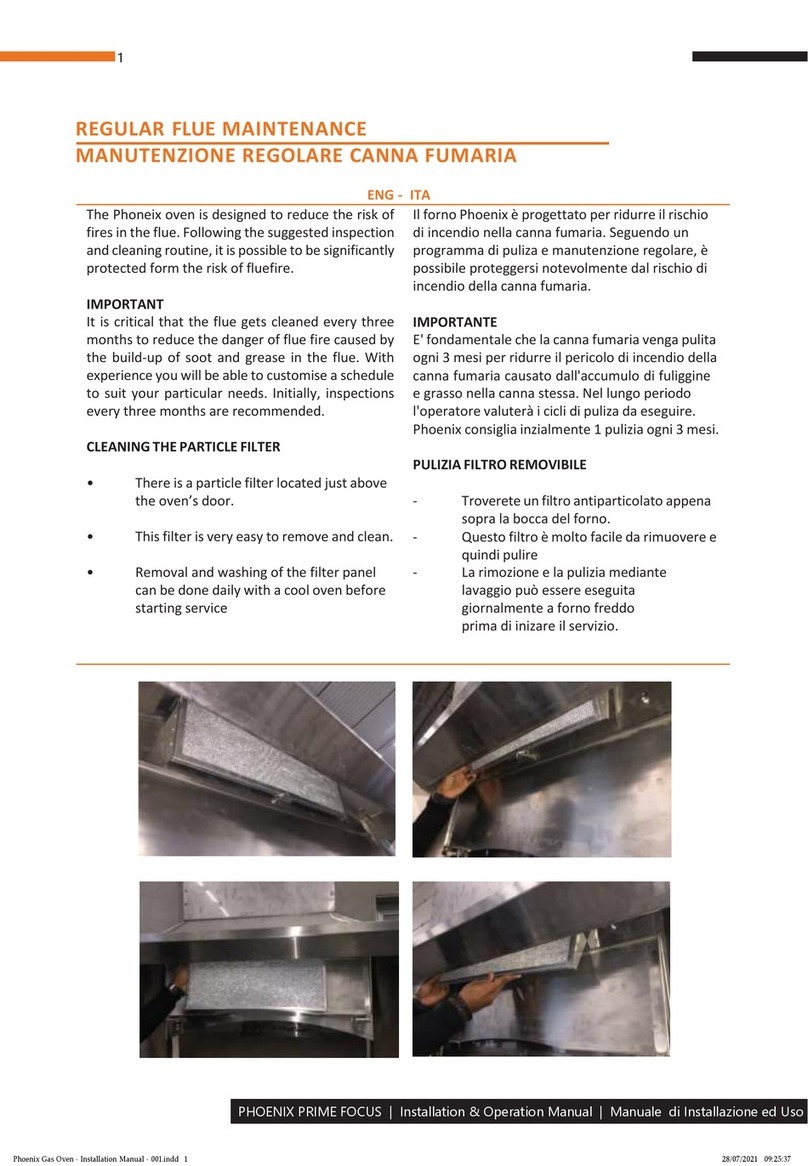

This oven was crated and packaged for long-distance shipment. Exercise care in

removing the oven from the wooden crate.

After oven is in final location, anchor as required, open the oven door and remove

packing material, manuals and loose parts.

Wiring

Check type and voltage on nameplate.

750HT (3/240V AC only)

750HT (3/480V AC only)

For 240V Wiring

Connect to a 240V, 50/60 cycle, 3 phase power source. Conduit openings (1/2")

are provided in the wiring compartment for this purpose. A three-pole disconnect

switch should be provided since there is no power switch in the oven itself. Use

30-amp fuse. A schematic diagram of internal wiring follows.

For 480V Wiring

Connect to a 480V, 60 cycle, 3 phase power source. Conduit openings (1/2") are

provided in the wiring compartment for this purpose. A three-pole disconnect

switch should be provided since there is no power switch in the oven itself. Use

15-amp fuse. A schematic diagram of internal wiring follows.

Amp Draw

Ovens operating on 240 AC voltage draw 25 amps. Those operating on 480 AC

voltage draw 12.5 amps.

Grounding

The 750HT ovens have a grounding lug in the upper control box.

Operation

1. A. Start-up (switch in “OFF” position)

2. Turn on power to the oven.

3. If red light is on, push the reset button to reset high limit control.

4. Set temperature controller at desired temperature by pressing the UP/DOWN

keys and then pressing ENTER.

Description of Controls

The controller in this oven is a full-indicating, PID (proportional, integral,

derivative) controller using a Type J thermocouple sensor. The controller is

factory set for optimum performance accuracy with a 400 pound load at

maximum temperature.

The high-limit control is a mechanical device with on-off control action. The

high-limit control will shut down the oven heat when the oven temperature

reaches the high-limit set point. In order to regain power to the heating

elements, the oven must cool down below the high-limit set temperature.

Controller

If any adjustments are required, they should be done by a qualified person with

the aid of the instructions contained in this manual or the Original Factory Setting

Guide (available upon request from Phoenix International). All instruments are

fully tested and adjusted for optimum performance prior to shipping the oven. If

the settings are lost for some reason, contact Phoenix International for the PID

Controller Original Factory Setting Guide.

Temperature Settings

Excess Heat: At maximum setting, the actual temperature in portions of the oven

near the heating elements may exceed the upper range.

Guide to Storage

Flux should be stored according to flux supplier recommendations. In the absence

of storage information from your electrode manufacturer, please reference

Phoenix's Guide To Electrode and Flux Stabilization for approximate temperatures,

found at www.dryrod.com/guide.

CAUTION

• Disconnect power and make sure oven is cooled before opening

or servicing unit.

• Hot Surfaces! Use extreme care to avoid possible burns or personal injury.

Protective gloves and personal protective equipment are recommended.