Manual POWM01 / POWM02

MA 1273-A004 EN 6

2 Contents

1Legal Instructions .................................................................................................. 3

2Contents..................................................................................................................6

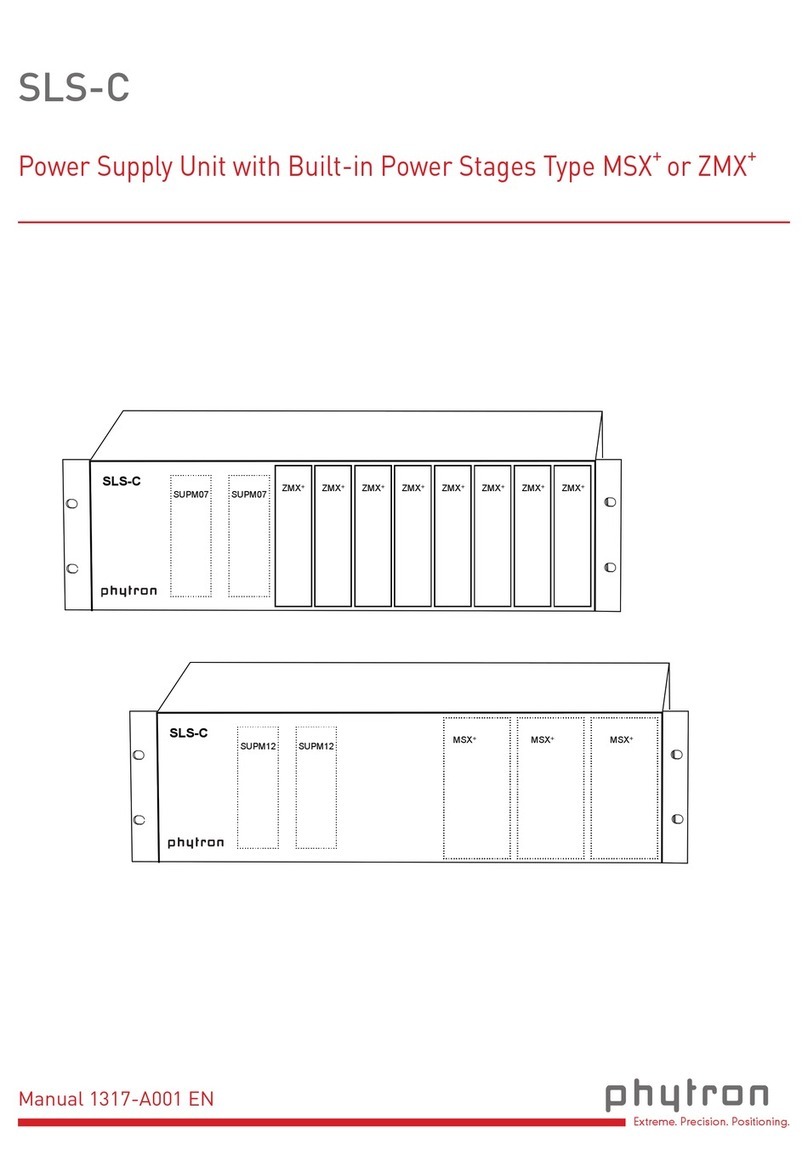

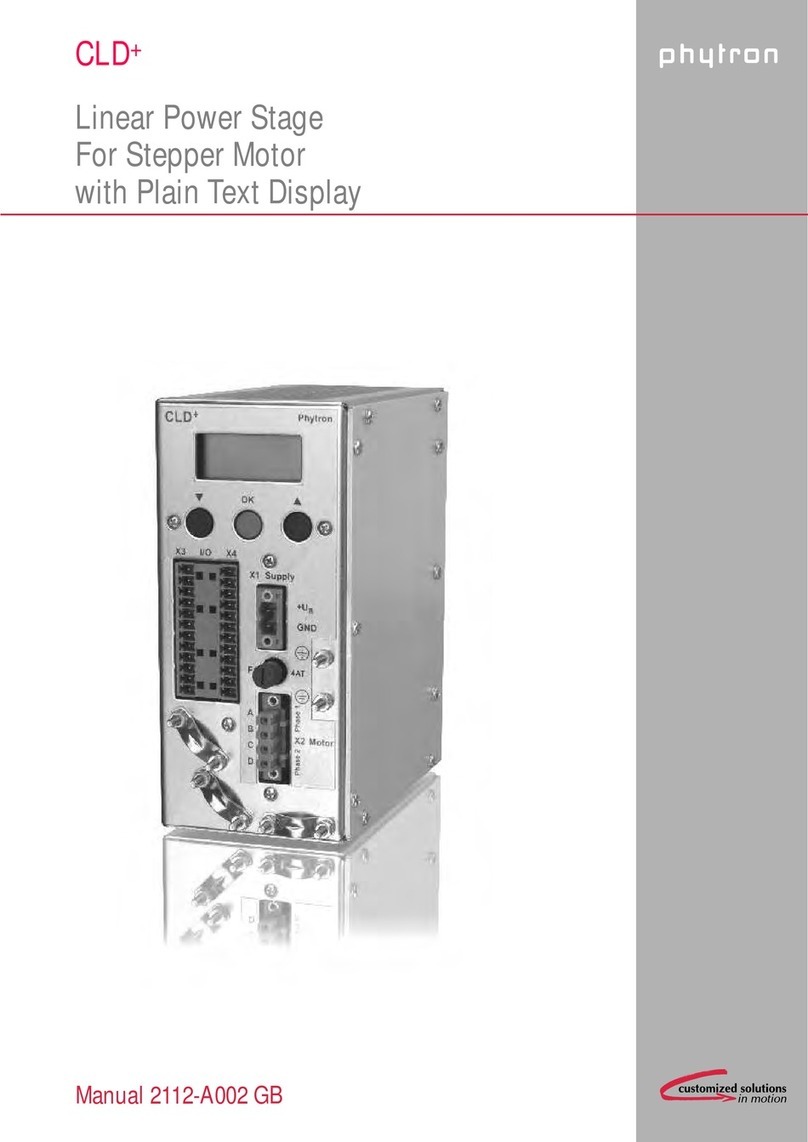

3POWM01 / POWM02 Module Overview ................................................................. 7

4Technical Data......................................................................................................10

4.1 Declaration of Incorporation.............................................................................. 10

4.2 Mechanical Data............................................................................................... 11

4.3 Features POWM01........................................................................................... 12

4.4 Features POWM02........................................................................................... 13

4.5 Functions .......................................................................................................... 14

5Installation ............................................................................................................15

5.1 Mechanical Installation ..................................................................................... 15

5.1.1 Assembly Rules......................................................................................... 17

5.2 Electrical Installation......................................................................................... 18

5.2.1 Connectors - Overview .............................................................................. 18

5.2.2 Pin Assignment POWM02 ......................................................................... 19

5.2.3 Pin Assignment POWM01 ......................................................................... 20

6Commissioning .................................................................................................... 23

6.1 USB Driver Installation (Windows).................................................................... 24

6.2 DIP Coded Rotary Switch ................................................................................. 25

6.3 REMOTE/LOCAL Switch R/L ........................................................................... 25

6.4 Diagnostic by LED Display ............................................................................... 26

6.5 Reset Button..................................................................................................... 27

7Parameterising the Module.................................................................................. 28

8Service ..................................................................................................................29

9Version / Compatibility......................................................................................... 29

10 Warranty, Disclaimer and Registered Trademarks ............................................ 30

10.1 Disclaimer.................................................................................................... 30

10.2 Warranty......................................................................................................30

10.3 Registered Trademarks ............................................................................... 30

11 Index...................................................................................................................... 31