phytron

3 MA 1317-A001 EN

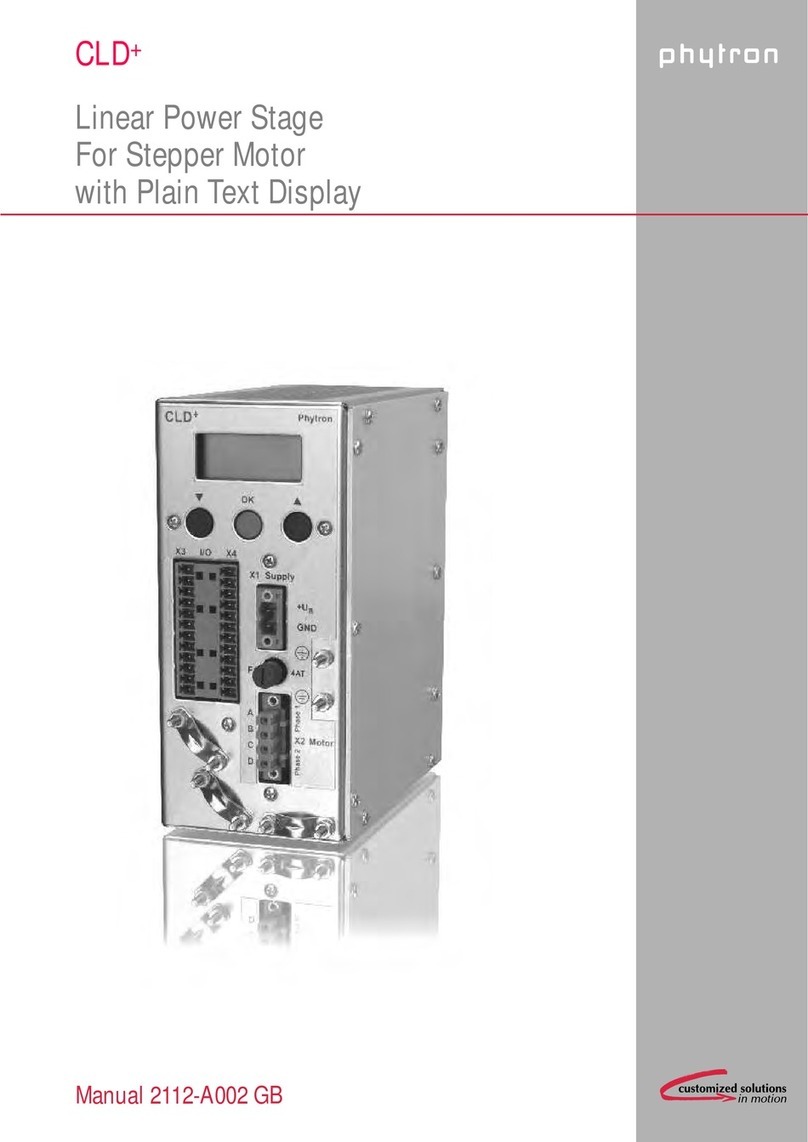

Contents

1Legal Information..........................................................................................................4

2Brief description of the SLS-C.......................................................................................8

2.1 MSX+and ZMX+Power Stages.....................................................................................9

2.2 SLS-C with Customised Unit Design.............................................................................9

3Transport and Storage Information .............................................................................10

4Suitable Installation Location ......................................................................................11

5Mounting Information..................................................................................................12

6Protective Measure for Power Supply Units with Power Stages up to 70 VDC.............13

7Protective Measure for Power Supply Units with Power Stages up to 120 VDC...........14

8Cabling Design Requirements ....................................................................................15

9EMC Requirements.....................................................................................................16

10 Mains Connection.......................................................................................................18

11 Control Pulses Connector - Standard..........................................................................20

12 Motor Connector and Connection - Standard..............................................................21

13 ServiceBus Operation.................................................................................................23

13.1 Interface Connector RS 485 .................................................................................23

13.2 The connection of the SLS-CZMX+ acc. to RS 485 (4 wire operation):.................23

14 ESD Protection Measures...........................................................................................25

15 Warranty.....................................................................................................................25

16 Index...........................................................................................................................26