VACUUM CONVEYORS

5

Exhaust from the vacuum pump

The exhaust air from the conveyor’s vacuum pump

may, in certain applications, constitute a risk and

cause injuries. If the filter is not fully intact when pow-

der with small particles is conveyed, the particles may

penetratethefilterand enter the pump, andfurtheron

out to the atmosphere and possibly contaminate it.

Dangerous gases may also be generated and be car-

ried out together with the exhaust air. In such cases

the pump shall be fitted with a central exhaust with an

external filter. In certain cases, another alternative

could be the use of a sterile-filter unit. Never look di-

rectly into the outlet of the vacuum pump. Do not for-

get to disconnect the supply of compressed air when

cleaning or servicing the vacuum conveyor

Compressed air

We recommend that compressed air of at least quality

class 3 is used (ISO norm 8573.1) for PIAB’s vacuum

pumps. This means that only a maximum of 5 mg/m3

of a maximum of 5 µ size particles may be present in

the compressed air.

For the USDA conveyor to conform to the American re-

quirements of the authorities, the air for the air shock

must be delivered according to 3-A Accepted Practice

No. 604-04. This means, among other things, that the

air shall be free from oil and be filtered.

Preventing pressure-drops in

the air supply

It is important to correctly dimension the compressed-

air hose that supplies the conveyor so that unneces-

sary pressure drops do not occur. The longer the hose,

the larger the dimension required. Also remember

thatpush-inconnections with built-innon-returnvalves

may cause pressure drops. Also, take into consider-

ation that there may be other devices in the com-

pressed-air network that might consume compressed

air.

Dimensioning of the compressed-air pipeline

A very important part of a vacuum system is correctly

dimensioned hoses and connections. In order to get

the highest possible performance from each vacuum

pump, the table below that recommends hose diame-

ters in mm (inner diameter) should be used.

The above compressed-air connections apply for pipe-

lines that are shorter than 10 m (33 ft). If the pipeline

is longer than 10 m (33 ft), select a pipeline of a larger

diameter.

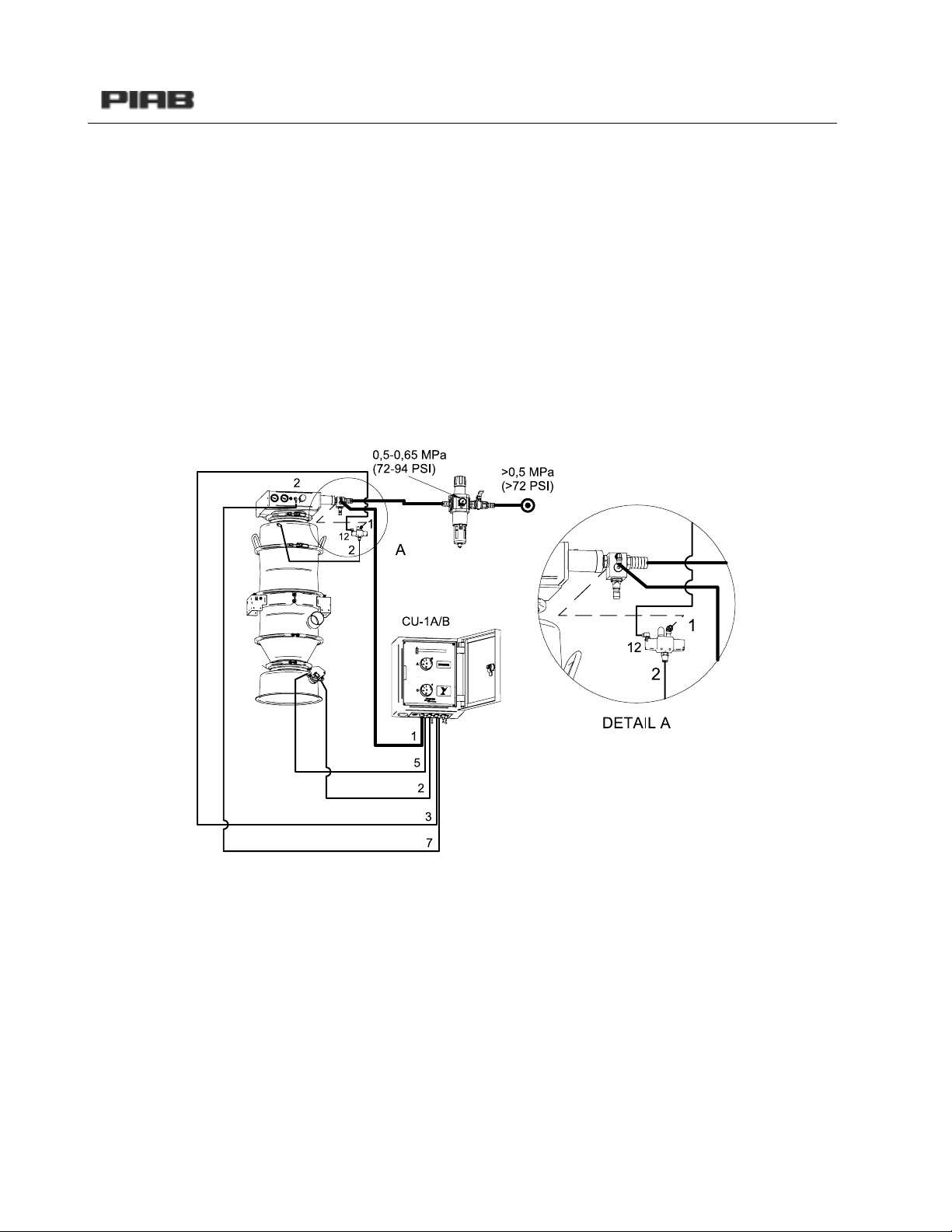

Installation of compressed air

The feed pressure of the compressed air is between

0.4(58)and0.6 (87 psi) MPaforPIABvacuum convey-

orsandpumps.Careless usage ofcompressedairmay

cause injuries.

The compressed air may not be used for any other pur-

pose than specified.

All applicable safety regulations for installation, opera-

tion and maintenance must be followed.

Always disconnect the supply of compressed air when

cleaning or servicing the vacuum conveyor.

You are responsible for your own and other people’s

safety at the place of work.

Contact your local PIAB distributor if you have any

questions.

Pump model Compressed-air

connection

Exhaust connec-

tion (mm)

Maxi L100 1/2" 75

Maxi L200 1/2" 75

Maxi L400 1/2" 75

Maxi L600 1" 2x75

Maxi L800 1" 2x75

Maxi L1200 1" 2x75

Maxi L1600 1" 2x75