English

Work cycle details

The working cycle for a KVG gripping module follows the different technologies involved:

Check valve balls version(CVL/CVM/CVH):

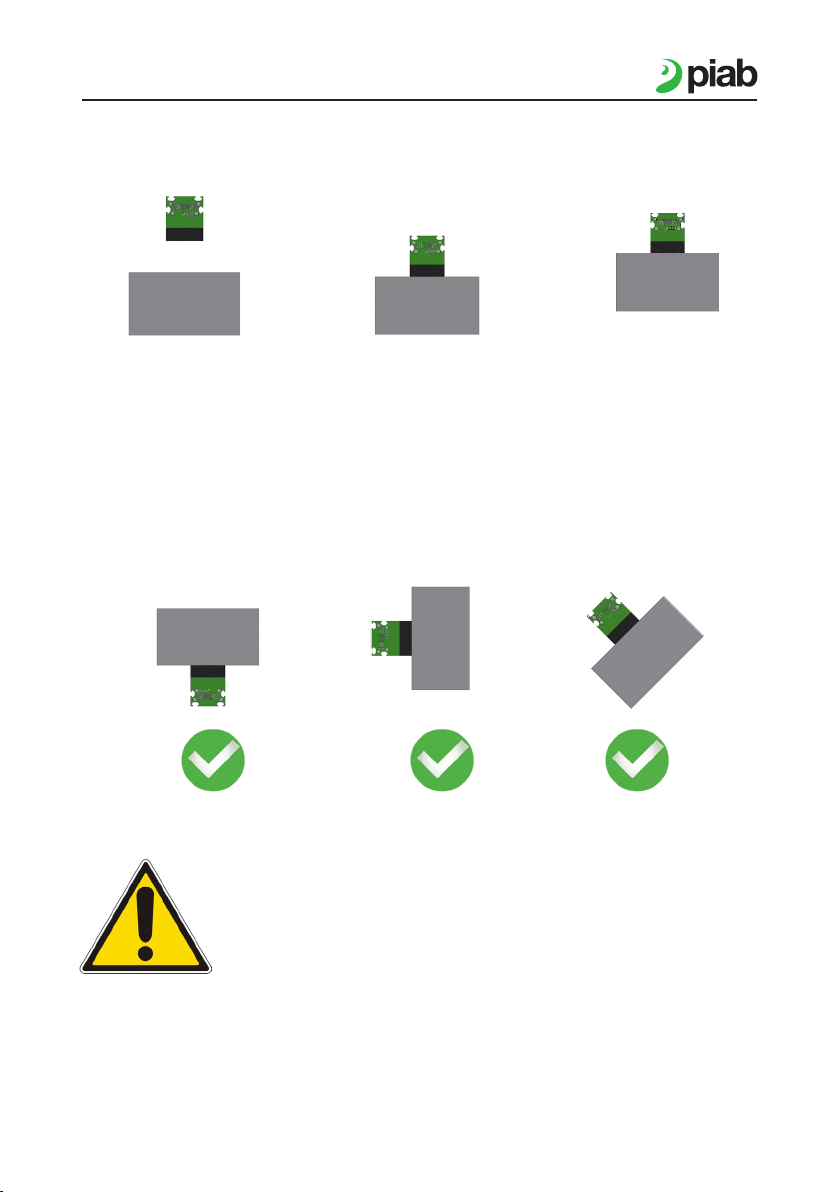

1. Positioning the module at the object to handle with the grip pad parallel to the grip surface.

2. Lowering of module until contact with the grip surface

3. Sequential activation of vacuum if multiple modules are present

4. Pick-up of object to handle

5. Drop-off of object with removal of vacuum and blow-off if necessary

N.B. If vacuum is activated before KVG is in contact with the workpiece, the work-

piece will not be gripped because the check valves will be closed and not allowed

the handling.

►The KVG CVL/CVM/CVH gripper module was designed for horizontal

use; turning the module upside down by 180°, or vertical grips are not

possible. Maximum tilt allowed is 45°.

►Stopping or passing through the work area of the gripper module is

prohibited, as in case of electrical or pneumatic supply failure, the

load handled by the module is released.

►The maximum vertical acceleration allowed is 5 m/s².

►Note that when check valves are present in the KVG module, the

vacuum value you can measure through a vacuum switch cannot be

used as indication for a safe grip of the object. This because we are

detecting the vacuum level inside the gripping module and, thanks to

the acting of the CV, it will be high even when the object is not present

(CV will close).

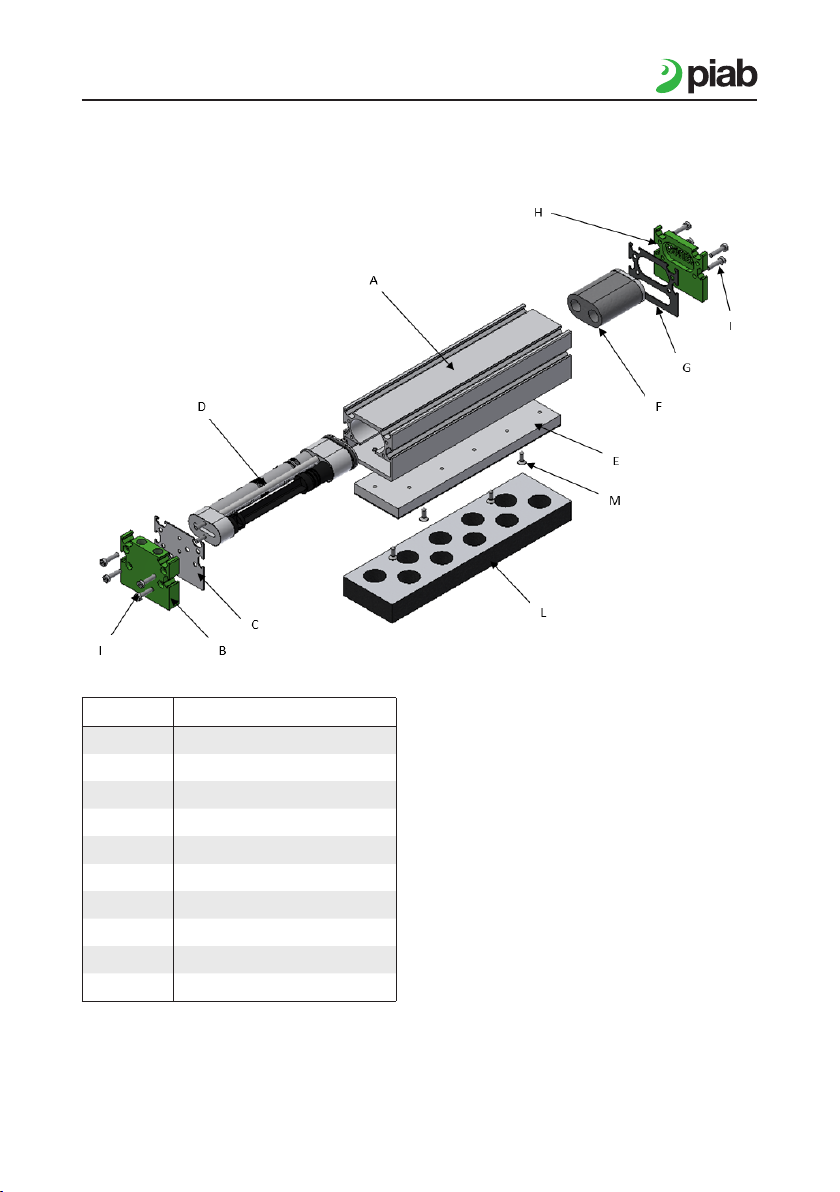

KVG60 Series

Specications subject to change without notice

5