7

Mini Miller 8/17 WARNING

!

The Mini Miller powers the Mini Coang Pump

Note: can also be used with the Micro Miller

Please refer to the Mini Miller manual

for more informaon

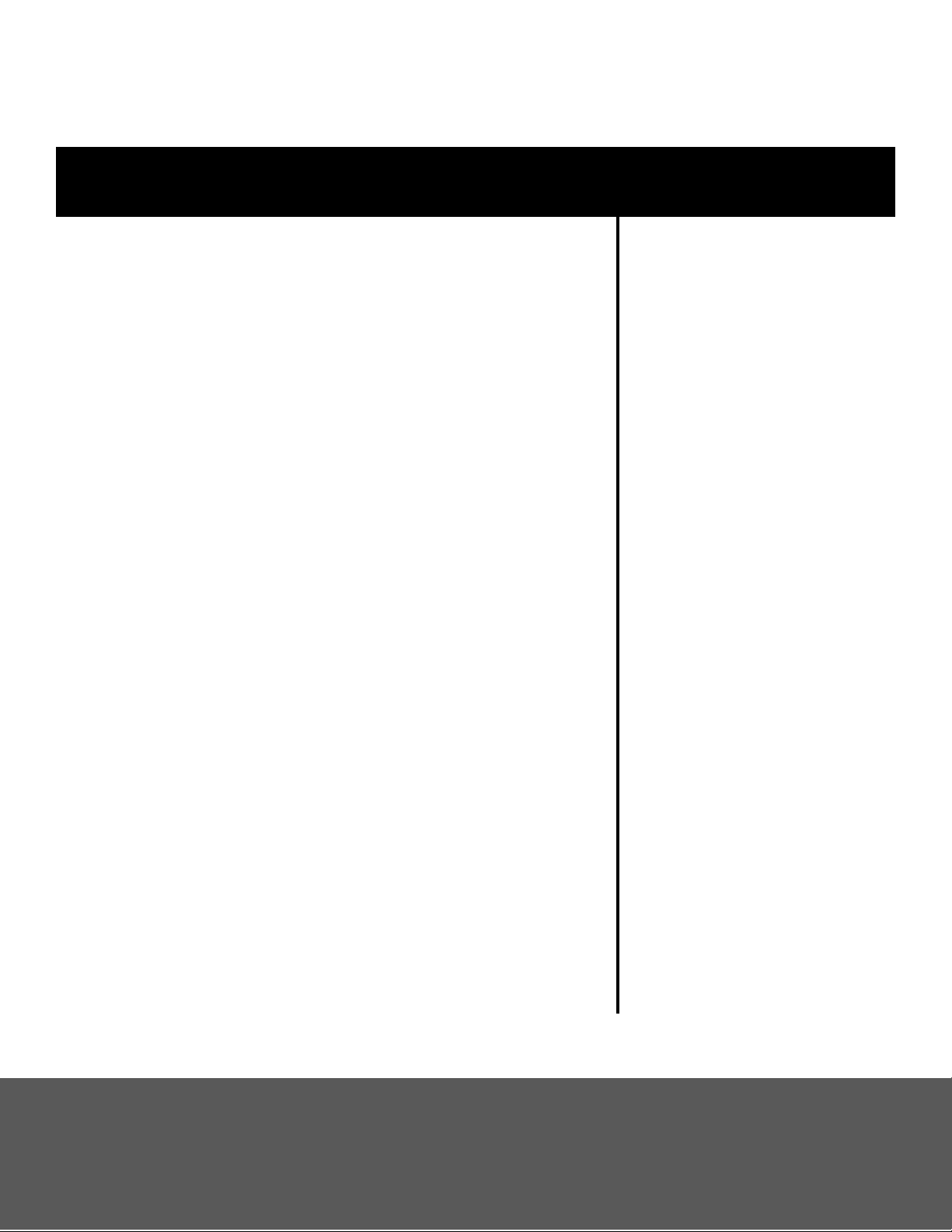

General Descripon

Cable Rack

Frame

Flexible Sha

Motor & Bevel Gear (not shown)

Emergency Stop Boom (red)

Power Switch

Speed Control

Foot Pedal—Operator Presence Control

Hand Guard & Strain Relief/inside Hand

Guard (not seen in photo)

1.

2.

3.

4.

5.

6.

7.

8.

9.

Intended Use

This machine is intended for the following uses:

1. Coang pipes from DN32-200 / 1.1/4’’- 8’’

2. Cleaning sewers, drains and pipes by grinding.

(Picote Grinding Chains)

3. Reinstang branches in sewers and drains by

drilling and grinding. (Picote Lateral Cuer)

Always follow the manufacture’s instrucons when

installing and using the machine with accessories.

SIZE SHAFT RANGE ROTATING SPEED OUTPUT (kW) POWER SOURCE WEIGHT

752x519x389 8mm 17m 500-2900rpm 110V:1.1kW 110v or 230v 27kg

29.6x20x15.3’’ 1/3’’ 55 230V:1.2kW 59.5lb

When is use, always lay the machine down horizontally on the oor as shown above. When not in use, some

non-hazardous Picote Flexible Sha Lubricant might leak from the hand guard.

1

2

3

4

5

6

9

8

7

VOLTAGE

Ensure that the supply voltage is correct. The volt-

age of the power source must match the value giv-

en on the nameplate of the machine.

FOOT PEDAL

The machine has an operator presence control

or ‘OPC’. When the control is not held down,

the machine stops.

POWER SUPPLY

The machine should be connected only to a power supply

of the same voltage as indicated on the nameplate, and

can only be operated on single-phase AC supply.

EMERGENCY STOP

There is an Emergency Stop Buon on the machine. The pow-

er supply to the motor is cut o when the Emergency Stop

Buon is pushed. Always make sure the Emergency stop

Buon is pressed and completely unplug the machine when

the machine accessories (e.g. Cuer or Grinding Chains) are

not inside the pipe.