Contents

Operating Manual PZE X4.1P

1003203-EN-09 | 3

Introduction ............................................................................................................................4

Validity of documentation.......................................................................................................... 4

Using the documentation .......................................................................................................... 4

Definition of symbols................................................................................................................. 4

Safety ...................................................................................................................................... 5

Intended use ............................................................................................................................. 5

Safety regulations ..................................................................................................................... 5

Safety assessment ................................................................................................................... 5

Use of qualified personnel ........................................................................................................ 6

Warranty and liability ................................................................................................................ 6

Disposal .................................................................................................................................... 6

For your safety.......................................................................................................................... 6

Unit features ...........................................................................................................................7

Safety features ....................................................................................................................... 7

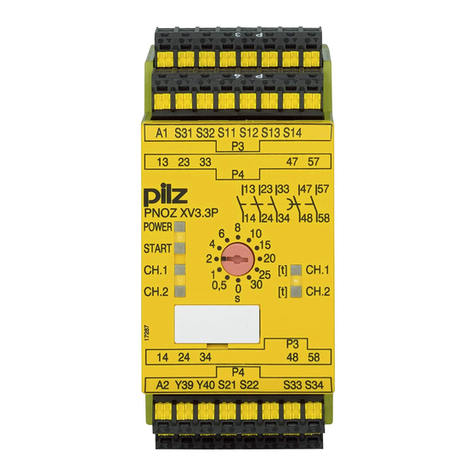

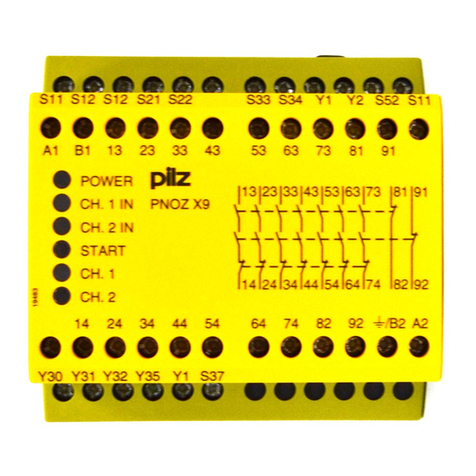

Block diagram/terminal configuration ................................................................................. 8

Type: DC................................................................................................................................... 8

Type: AC/DC............................................................................................................................. 8

Function description ............................................................................................................. 9

Installation ..............................................................................................................................9

Wiring ......................................................................................................................................9

Preparing for operation ......................................................................................................... 10

Operation ................................................................................................................................11

Status indicators ....................................................................................................................... 11

Faults – Interference .............................................................................................................. 11

Dimensions in mm .................................................................................................................12

Technical details ....................................................................................................................12

Safety characteristic data ......................................................................................................... 20

Supplementary data ..............................................................................................................20

Service life graph ...................................................................................................................... 21

Remove plug-in terminals ..................................................................................................... 22

Order reference ......................................................................................................................22

EC declaration of conformity ................................................................................................ 23