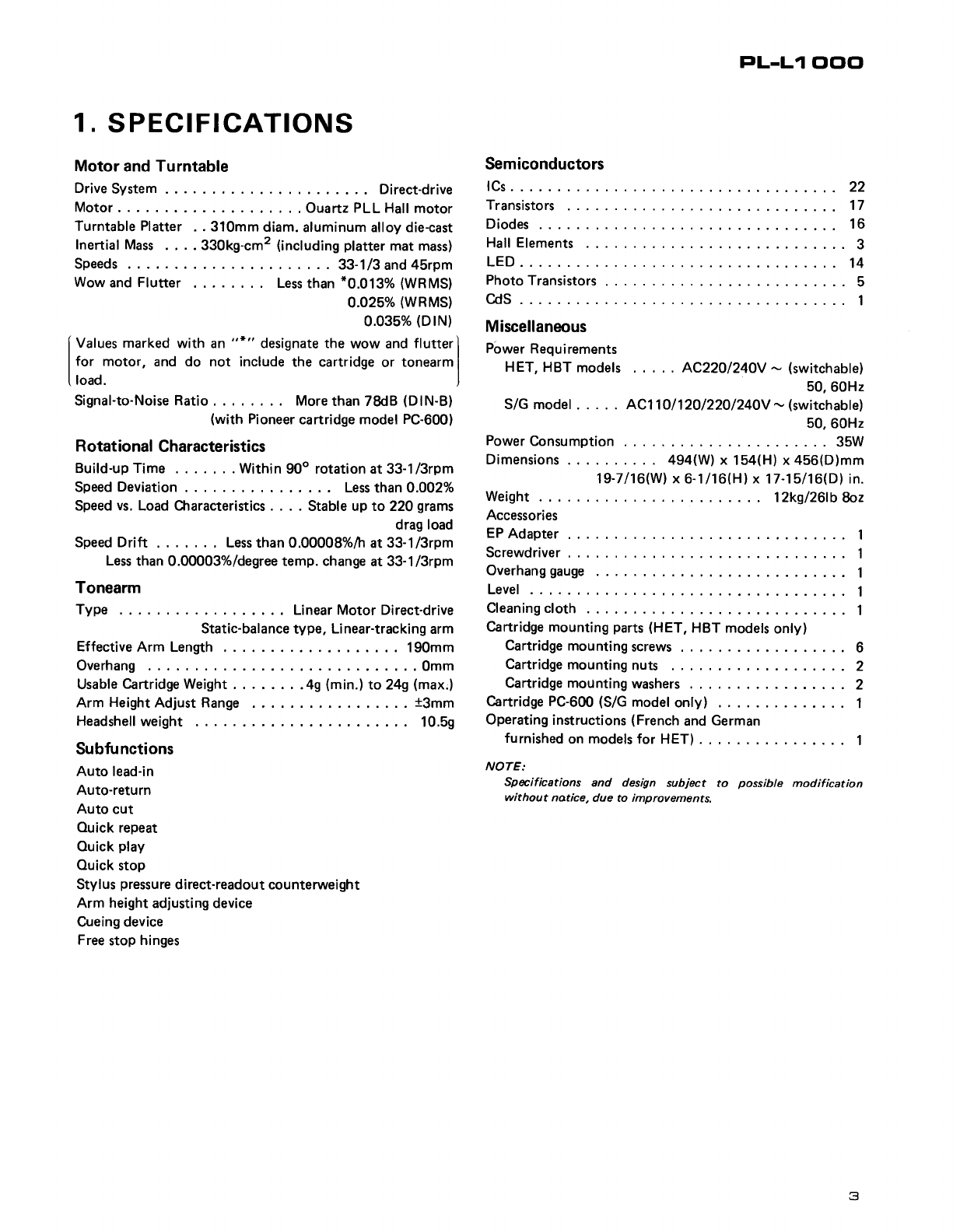

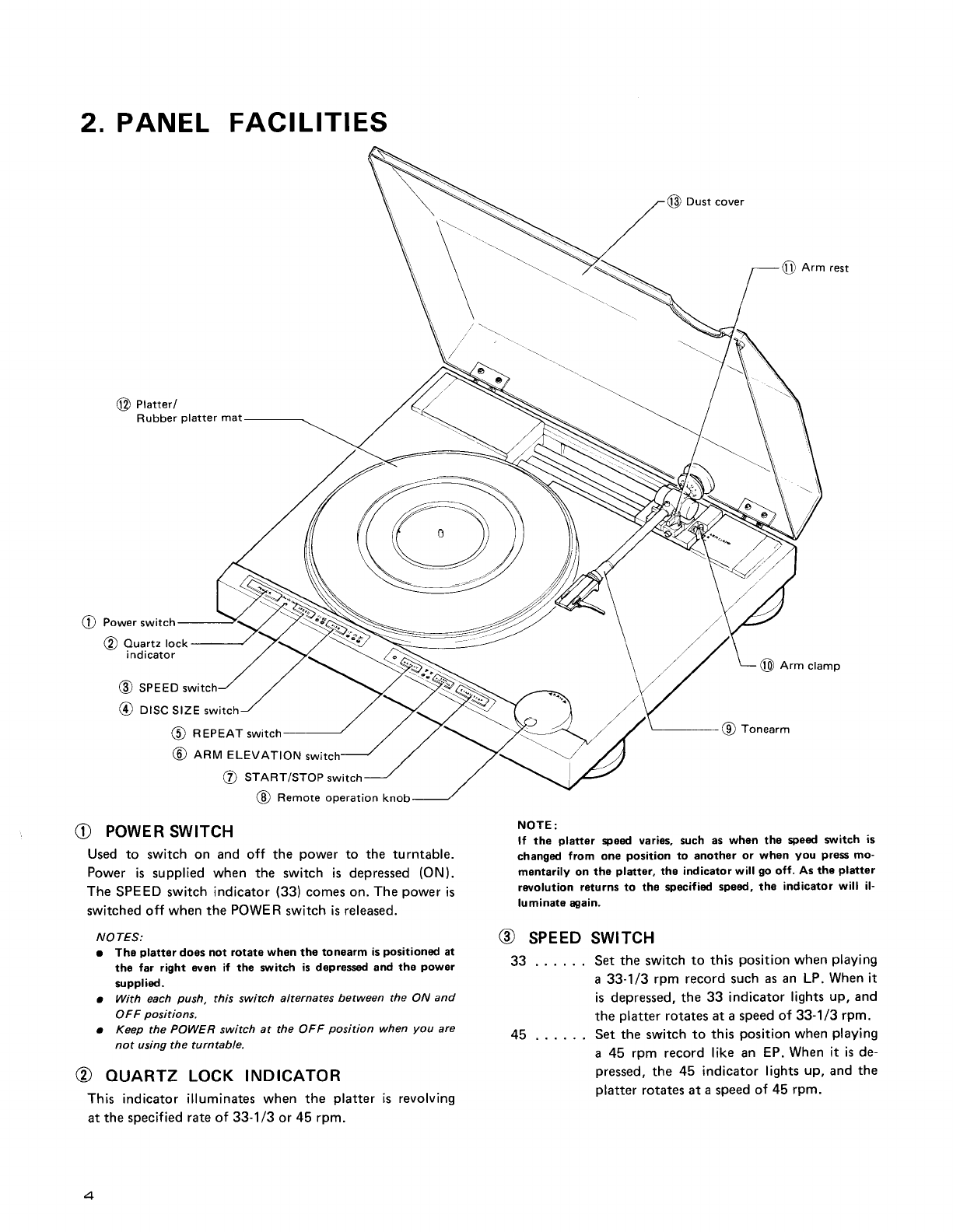

t@ Drsc

srzE

swrrcH

Selectsthe switchthatcorresponds

to thesize

of the

rec-

ord

youwant

to hear

for auto

play

operation.

12"30 . . . For

30cm

records

10"25 . . . For

25cm

records

7"17 . . . ForlTcmrecords

o Used

to select

the record

size

when

depressed.For in-

stance,

when

the30cmindicator

lights

up,

depress

the

switchfor the 25cm

position,

and

depress

it again

for

the 17cmposition.

Depressing

the switch

once

more

setsit to the

30cm

position.

o When

the power

switchis

turned

ON,theturntable

will always

be set for records

with a diameter

of

30cm

andthe

corresponding

light

will

come

on.

NOTE:

This sruitch will not work if depressed when the tonearm is

moving

(auto lead-in,

auto-return,

auto cut).

@ REPEAT

swtrcH

Press

this switchfor repeat

play.

When

pressed

the indi-

cator

will lightup, andthe record

will beplayed

again

(refer to page 12 for further details

on repeat

play).

Press

this

switch

again

to release

it. The indicator

will go

off andtherepeat

play

function

will bereleased.

NOTE:

This slitch will not work if depressed wh6n the ton€arm is

moving (auto-return, auto cut).

@ enruELEVATIoN

swtrcH

Usethis switchto interrupt

play temporarily

or to per-

form

manual

play.

When

the DOWN

position

is depressed

thetonearm

will

descend

and

whenthe UP

position

isdepressed

thetone-

arm will rise.

These

two operations

will beperformed

al-

ternatelyevery

timethe

switchis

pressed.

NOTES:

r When th€ POWER switch is setto ON, the tonearm will start

in the UP position.

r This switch will not work if depressed

when th€ tonearm is

moving (auto lead-in,auto-return. auto cutl.

o When the switch is at UP, tho auto-return cancelling mecha-

nisrnis actuated and so there will be no auto-roturn.

O sranr/srop

swtrcH

Press

thisswitch

for auto

play.

The

platter

will start

to ro-

tate, the tonearm

will automatically

moveover to the

edge

of therecord

and

play

will begin

(auto

lead-in).

lf this switch is pressed

during play, the tonearm

will

automaticallyreturn

to thearmclamp

position,

the plat-

ter will stop rotating

andplay will be suspended

(auto

cut).

NOTE:

This saritch will not work if depressed when the tonearm is

moving(autolead-in).

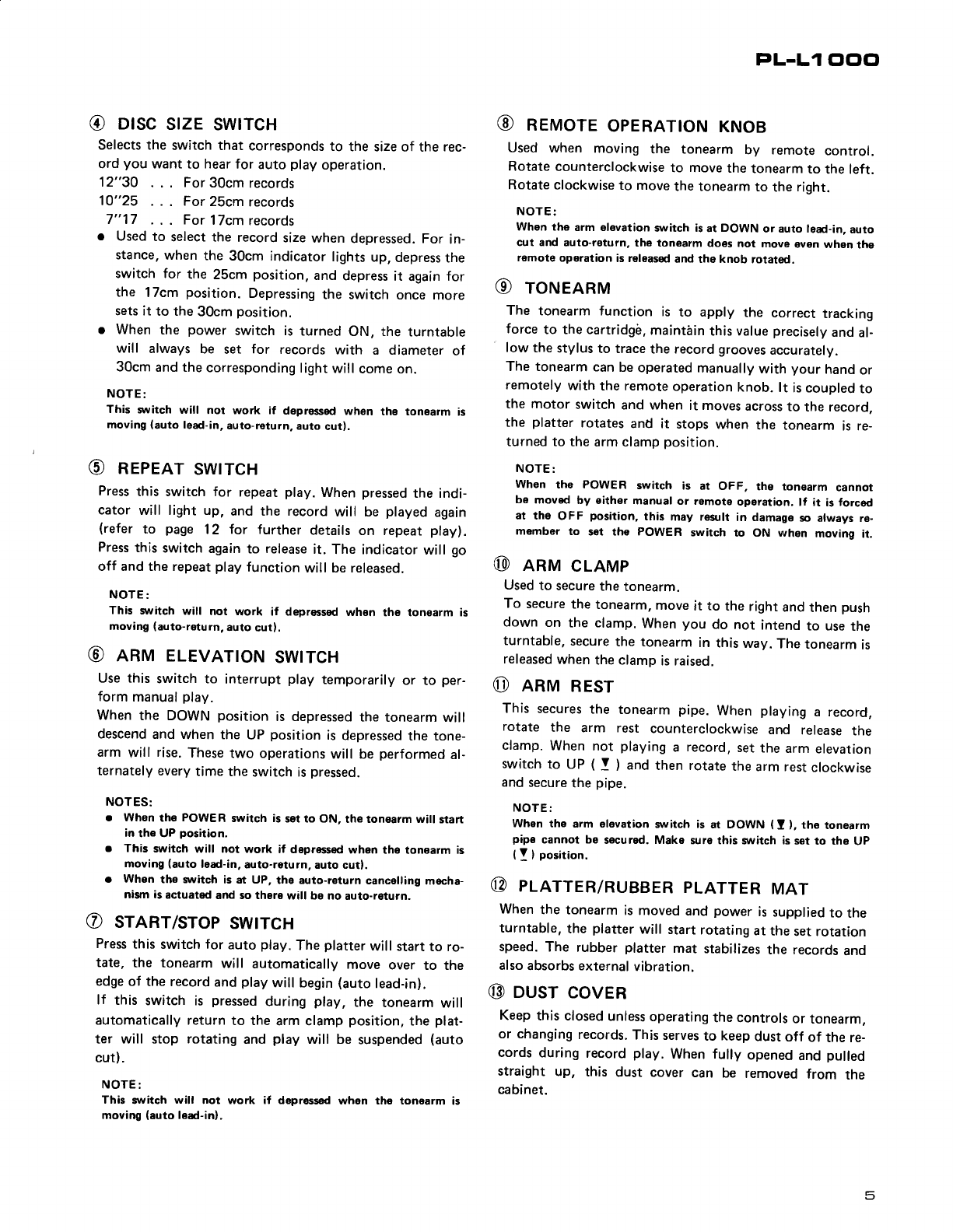

PL-L1 Clclc'

@ REMoTE

opERATtoN

KNoB

Used when moving the tonearm by remote control.

Rotate

counterclockwise

to move

the

tonearm

to theleft.

Rotate

clockwise

to move

thetonearm

to theright.

NOTE:

Whon the arm elevation switch isat DOWN or auto lead-in,

auto

cut and auto-return, the tonearm does not move even when the

remote operation is released

and th6 knob rotated.

@ ToNEARM

The tonearmfunction is to apply the correct

tracking

force

to thecartridge.

maintbin

thisvalue

precisely

and

al-

lowthe

stylus

to trace

therecord

grooves

accurately.

Thetonearm

can

be

operated

manually

with yourhand

or

remotely

withtheremote

operation

knob.

lt iscoupled

to

themotorswitch

andwhen

it moves

across

to therecord,

the platter

rotates

and it stops

whenthe tonearm

isre-

turnedtothe

armclamp

position.

NOTE:

When the POWER switch is at OFF, the ton€arm cannot

be moved by either manual or remote operation. lf it is forced

at tho OFF position, this may result in damage so always re-

member to set the POWER switch to ON when moving it.

@ ARM cLAMp

Used

to secure

the

tonearm.

To secure

the

tonearm,

move

it to the

right

and

then

push

down on the clamp.

When

you do not intend

to use

the

turntable,

secure

thetonearm

in this

way.

The

tonearm

is

released

when

theclamp

israised.

@ anru

REsr

Thissecures

the tonearm

pipe.

When

playing

a record,

rotate the arm rest counterclockwise

and release

the

clamp.

When

not playing

a record,

set

the

arm

elevation

switch

to UP( ! ) and

thenrotate

the

armrest

clockwise

and

secure

thepipe.

NOTE:

When the arm elevation sritch is at DOWN (l l, ttre tonearm

pipe cannot be secured. Make sure this sl,tritchis set to tho UP

(

! l position.

@ pIRIIER/RUBBER

pLATTER

MAT

When

thetonearm

ismoved

and

power

is

supplied

to the

turntable,

the platter

will start

rotating

atthe

setrotation

speed.

The rubber

platter

mat stabilizes

the records

and

also

absorbsexternal

vibration,

@

ousr covER

Keep

thisclosed

unless

operating

thecontrols

ortonearm,

or changing

records.

This

serves

to keep

dust

off of there-

cords

during

record

play.Whenfully opened

and

pulled

straightup, this dust cover

can be removed

from the

cabinet.

n

n'

t,

I