Pioneer PL-4 User manual

Other Pioneer Turntable manuals

Pioneer

Pioneer PL-V70 User manual

Pioneer

Pioneer PL-610 User manual

Pioneer

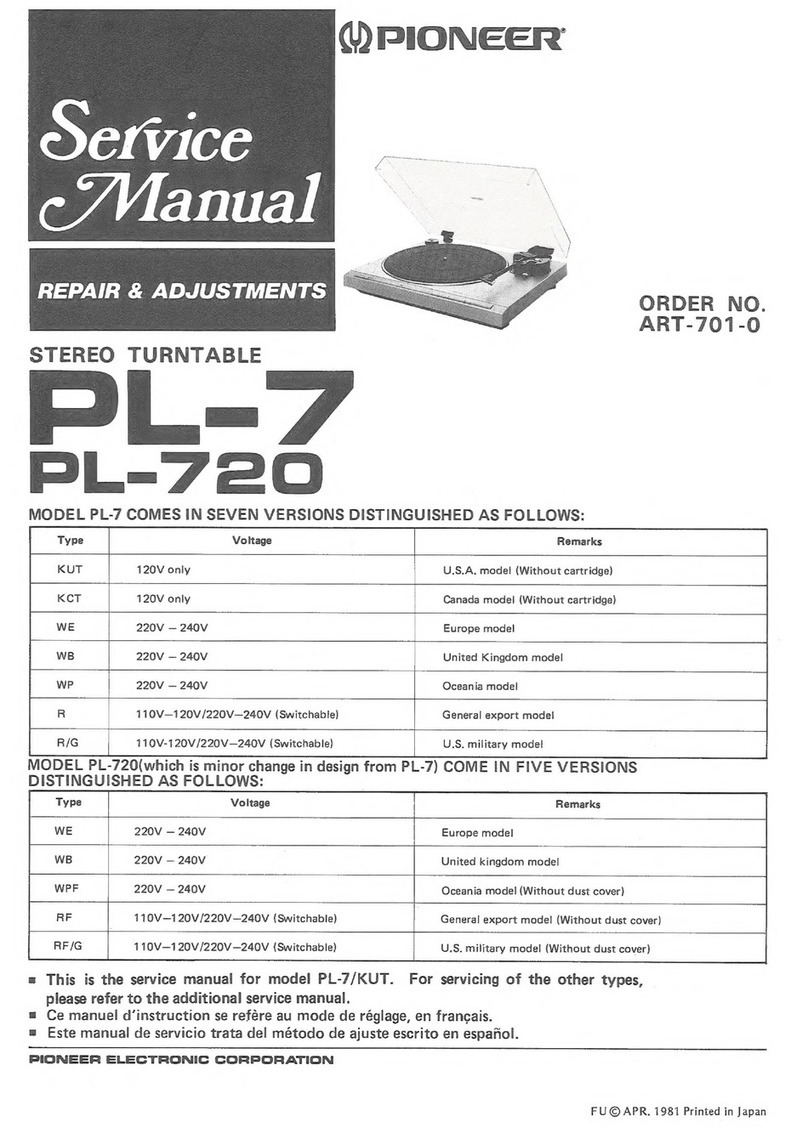

Pioneer PL-7 User manual

Pioneer

Pioneer PL-100 User manual

Pioneer

Pioneer PL-560 User manual

Pioneer

Pioneer PL-A45D User manual

Pioneer

Pioneer PL-A35 User manual

Pioneer

Pioneer PL-L1000 User manual

Pioneer

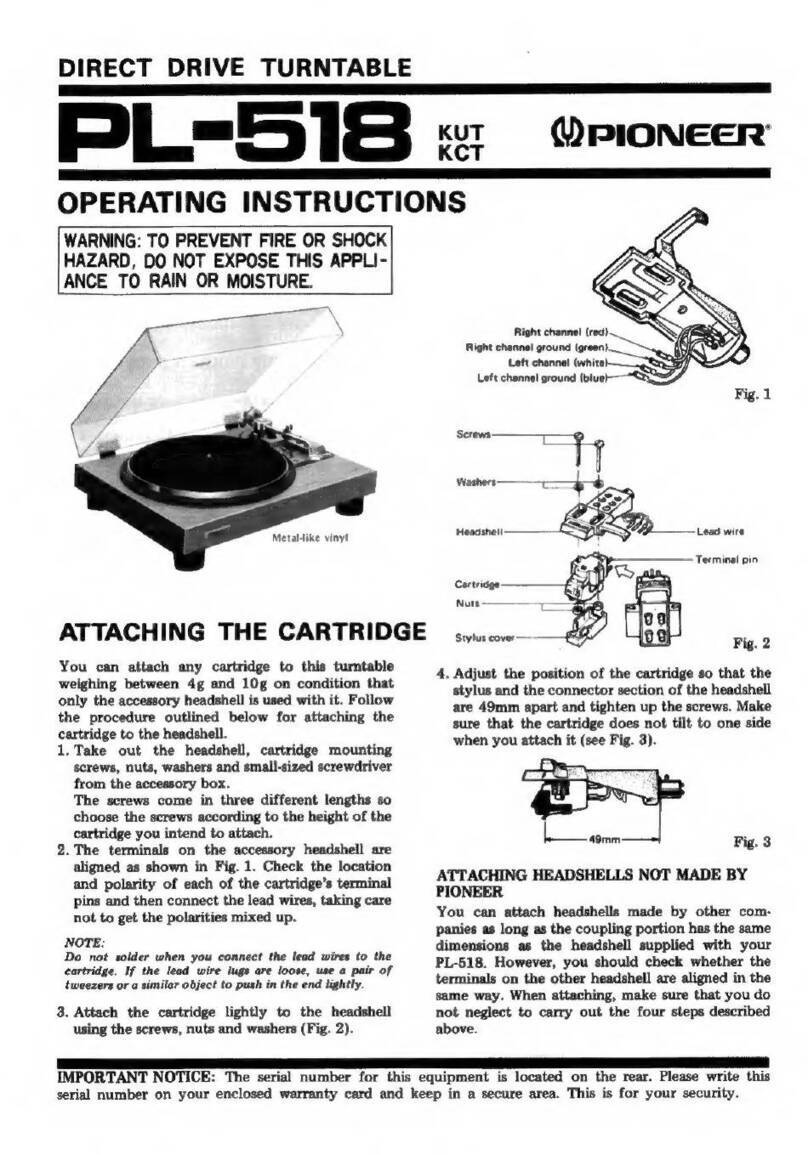

Pioneer PL-518 KUT User manual

Pioneer

Pioneer PL-Z93 User manual

Pioneer

Pioneer PL-12D User manual

Pioneer

Pioneer PL-55X User manual

Pioneer

Pioneer BDP-170 User manual

Pioneer

Pioneer PL-L70 User manual

Pioneer

Pioneer DEH-P6500 User manual

Pioneer

Pioneer PL-44F User manual

Pioneer

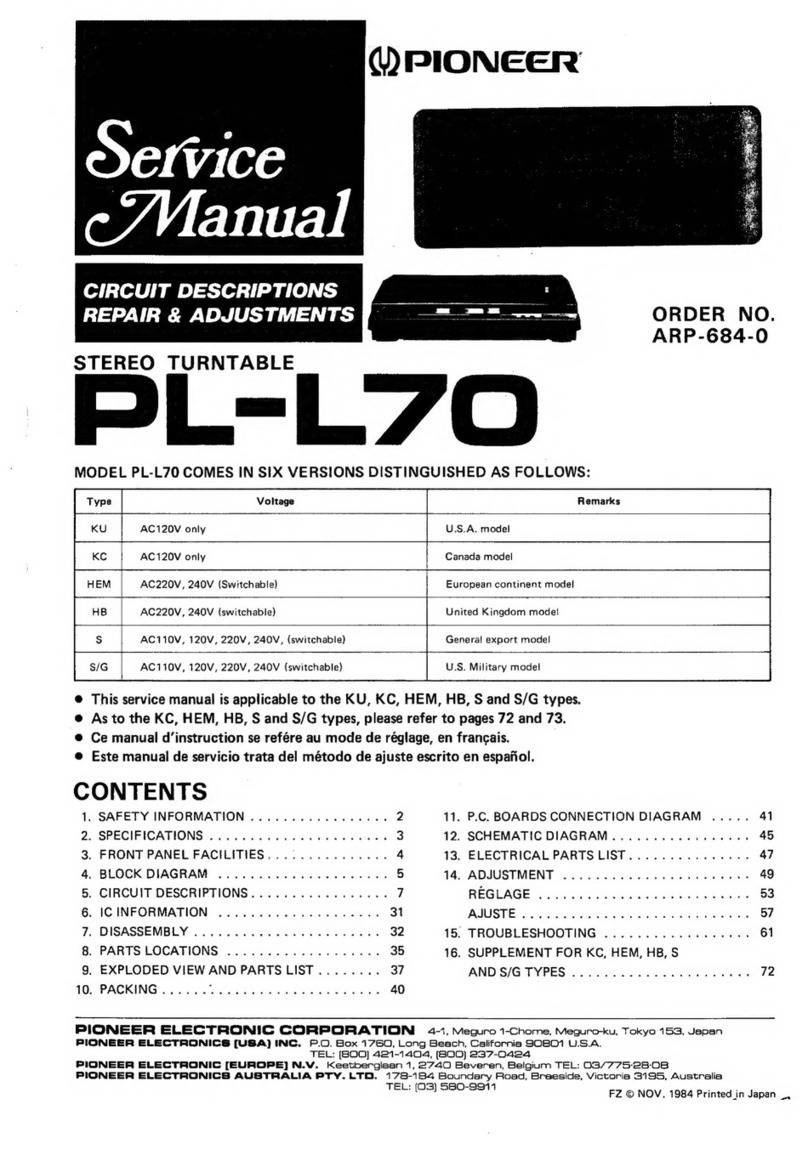

Pioneer PL-L70 User manual

Pioneer

Pioneer PL-260 KU User manual

Pioneer

Pioneer PL-88F User manual

Pioneer

Pioneer PL-50 User manual