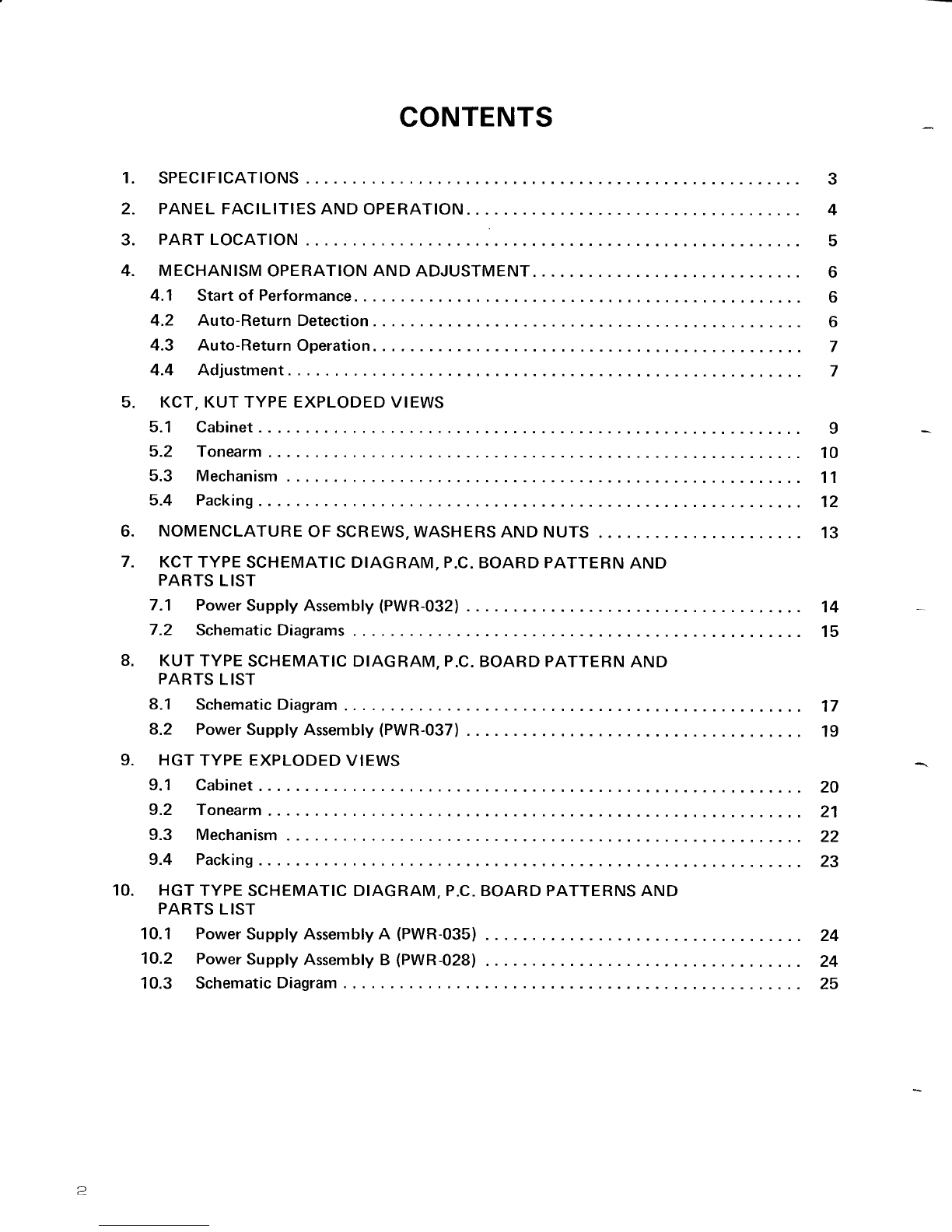

1.

SPECIFICATIONS

Motor andTurntable

Drive

System:

Motor:

Turntab!e

Platter:

Speeds:

Speed

Control

Range:

Wow

andFlutter:

Signal-to-Noise

Ratio:

Tonearm

Type:

Effective

Arm Length:

Overhang:

Tracking

Error:

UsablcCart

ridgeWeight:

Other Features

Auto-returnmechanism,

Anti-skating

force

control,Cueing

device

Detachabledustcover,

Insulator

feet,

Plug-intypeheadshell

Strobelight,40mm-thick

particle

board

cabinet

Direct-drive

DCservomotor

(t6 Pole

24

slot)

320mm

diam.

aluminum

alloy

die-cast

33-ll3

and45rpm

+2%

Lessthan

0.03%

(WRMS)

Morethan

73dB

(DlN

B)

(with

Pioneer

cartridge

model

PC-135)

Static-balance

type,

S-shaped

pipe

arm

221mm

I5.5mm

0.525

deg./in

,

0.21

deg.lcm

+g

(min.)

to'l0g

(max.)

AC120V,50/60H2

(KCT,

KUT)

AC220'240V

-, 50/60H2

(HGT)

7W

440(W)

x1as(H)x

365(D)mm

11-5116(W)

x s-ll/.16(H)

x 1a-3l8(D)

9.5kg/201b15oz

PL-51 El

HGT

only

For

Use

inUnited

Please

note:

Models employ 3 conductor mains leads. Please

read the f<tllowing instructions carefully before

connecttng.

WARNING: THIS APPARATUS

MUST BE

EARTHED.

CAUTION

240V: MAINSSUPPLY

VOLTAGE

IS FACTORY ADJUSTED

Ar 240

VOLTS.

IMPORTANT

The wires

in this mains

lead

are

coloured

tn

accordance

with

followingcode:

Green-and-yellow: Earth

Brown: Live

As the colours of the wires in the mains lead of

this apparatus may not cotespond with the

coloured marhings identifying the terminals tn

your plug, proceed as follows.

The wire which is coloured green-and'yellow

must be connected to the terminal in the plug

which is marked by the letter E or by the safety

earth symbol ! or coloured green or green-and-

yellow.

The wire tahich is coloured blue must be con'

nected to the terminal which is marked with

the letter N or coloured blue or black.

The wire which is coloured brown must be con'

nected to the terminal which is marhed with

the letter L or coloured brown or red.

The power cord should be connected last, mahe

sure that the Power sutitch is OFF.

First insert the female appliance connector of the

mains cord into the AC inlet, then plug the cord

to the wall socket.

Be sure the appliance connector is fully inserted

into the AC inlet.

Llnplug the set from the wall sochet when it rc

not to be used for an extended perioci of time.

FOR

YOURSAFETY

L lnsert this plug only into effectiuely earthed

three-pin plug-sctcket outlet.

2. If any doubt exists regarding the earthing,

consult a qualified electrician.

i). Extension cords, if used, musl be three'core

correctly uired-

Kingdom

and

Australia

Miscellaneous

PowerRequirements:

PowerRequirements:

PowerConsumption:

D

imensions:

Weight:

Accessories

EP

adaptor

Screwdriver

Cartridgemounting

screws

Cartridgemounting

nuts

Cartridgemounting

washers

Operatinginstructions(KCT, KUT)

Operating

instructions

(HGT) .

NOTE:

Specifications and design subject to possible modification

without notice,due to improuements.

I

l

6

2

2

I

2

3