Instructions for Use

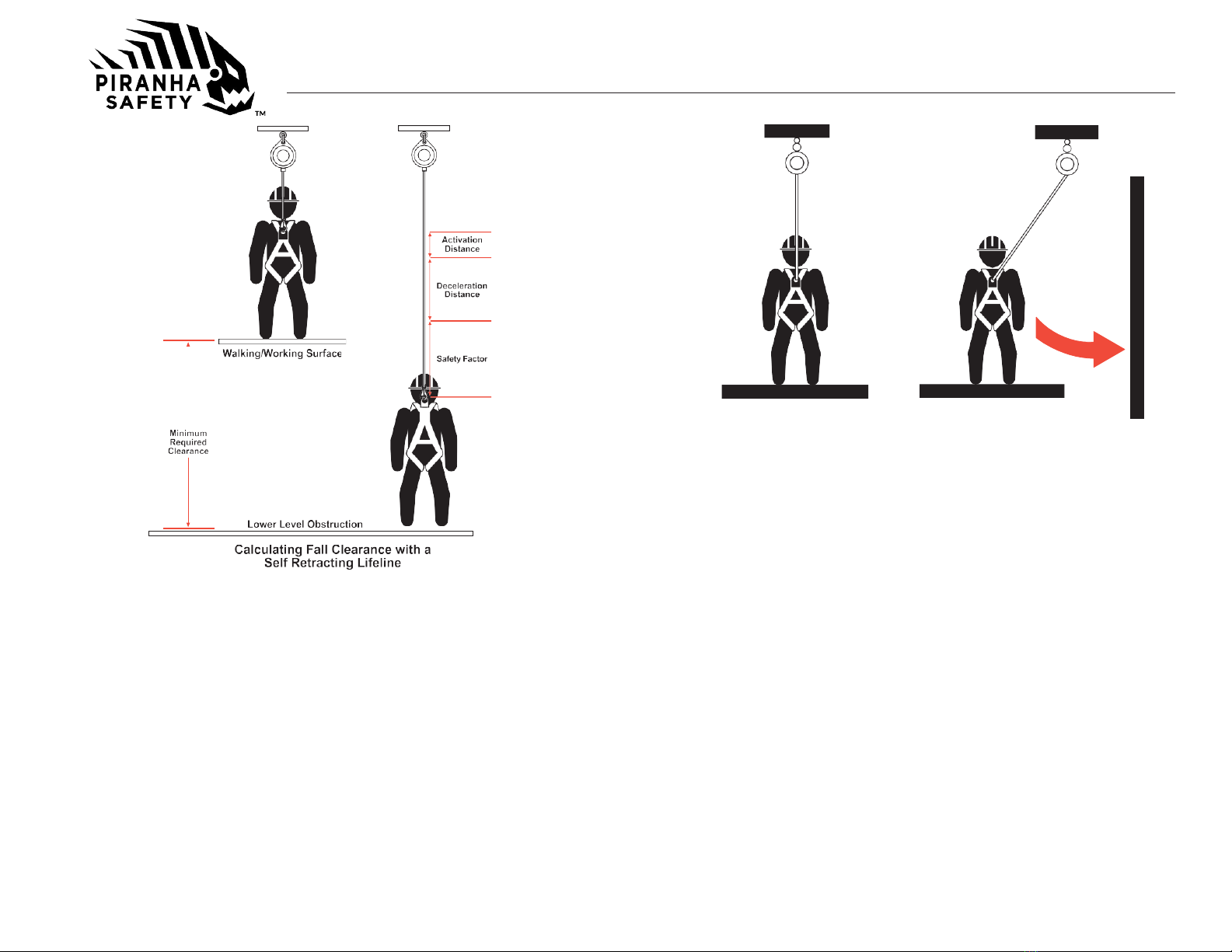

hazard also increases as the initial (before fall) length of extended

line is increased and as the initial angle which the line makes with the

vertical is increased. For example, if the initial extended line length

is 10 ft (3m), the drop at the bottom of the pendulum swing would be

1.3 ft (0.4m) This is in addition to the line extension due to the devices

internal shock absorption which may be as much as 3.3. ft (1m). The

total vertical fall distance would then be as much as 4.6 ft (1.4m) If,

however, 50 ft (15.2m) of cable is initially extended at a 30-degree

angle with the vertical, then a drop at the pendulum bottom of 6.7 ft

(2m) would result. In this example, adding the 3.3 ft (1m) of cable

extension due to internal shock absorption of the device, the total

vertical fall distance could be as much as 10 ft (3m).

Minimize swing falls by working as close to the anchorage point as

possible (see Figure 5). Do not permit a swing fall if injury could

occur. Swing falls will significantly increase the clearance required

when a self-retracting lifeline or other variable length connecting

subsystem is used.

5) CHEMICAL HAZARDS:

Acidic, alkaline, or other environments with harsh substances may

damage the webbing or synthetic rope (if equipped) and hardware

elements of this SRL. Polyester webbing is more resistant to attack

by acids but is subject to degradation by alkaline or neutral pH

environments. If working in a chemically aggressive environment, an

SRL that uses a cable lifeline is generally recommended. When

working in the presence of chemicals, more frequent inspection of

the SRL is required.

6) HEAT:

Do not use SRL’s that utilize a web lifeline in environments with

temperatures greater than 185°F (85°C). Protect the lanyard when

used near welding, metal cutting, or other heat producing activities.

Sparks may damage the line webbing or rope and reduce its strength.

7) CORROSION:

Do not expose the device to corrosive environments for prolonged

periods. Organic substances and salt water are particularly corrosive

to metal parts. When working in a corrosive environment more

Page 12

frequent inspection, cleaning, and drying of the SRL is required. For

the most severe environments the sealed SRL is recommended. See

Care and Inspection sections for cleaning and inspection details.

8) ELECTRICAL HAZARDS:

Use extreme caution when working near energized electrical sources.

Metal hardware on the SRL, the lifeline itself (on cable units), and on

other components connected to it will conduct electric current.

Maintain a safe working distance [preferably at least 10’ (3m)] from

electrical hazards.

9) MOVING MACHINERY:

When working near moving machinery parts (e.g. conveyors, rotating

shafts, presses, etc.), make sure that loose equipment is secured.

Maintain a safe working distance from machinery that could entangle

clothing, the lifeline, the harness, or other components connected to

it.

10) SHARP EDGES AND ABRASIVE SURFACES:

Do not expose web lifelines to sharp edges or abrasive surfaces that

could cut, tear or abrade and weaken the fibers. If working around

sharp edges and abrasive surfaces is unavoidable use heavy

padding or other protective barriers to prevent direct contact. An

energy absorbing component can sometimes be added in-line to

further protect the worker. Compatibility and total fall distance must

be considered if this is done. Contact Reliance/Piranha-Safety before

using an in-line energy absorbing component or lanyard with

an SRL. NOTE on Leading Edge SRL: Although this model provides

additional protection from falls occurring over edges, protection

against cutting must be provided when working near extremely

sharp edges such as sheared, cold rolled, or flame cut steel, or

rough cast edge concrete. Edge protection is not required over

edges such as hot rolled steel, steel decking, chamfered concrete,

or wood.

11) WEAR AND DETERIORATION:

Any SRL which shows signs of excessive wear, deterioration or

aging, must be removed from use and marked “UNUSABLE” until

destroyed. See detailed inspection procedures.

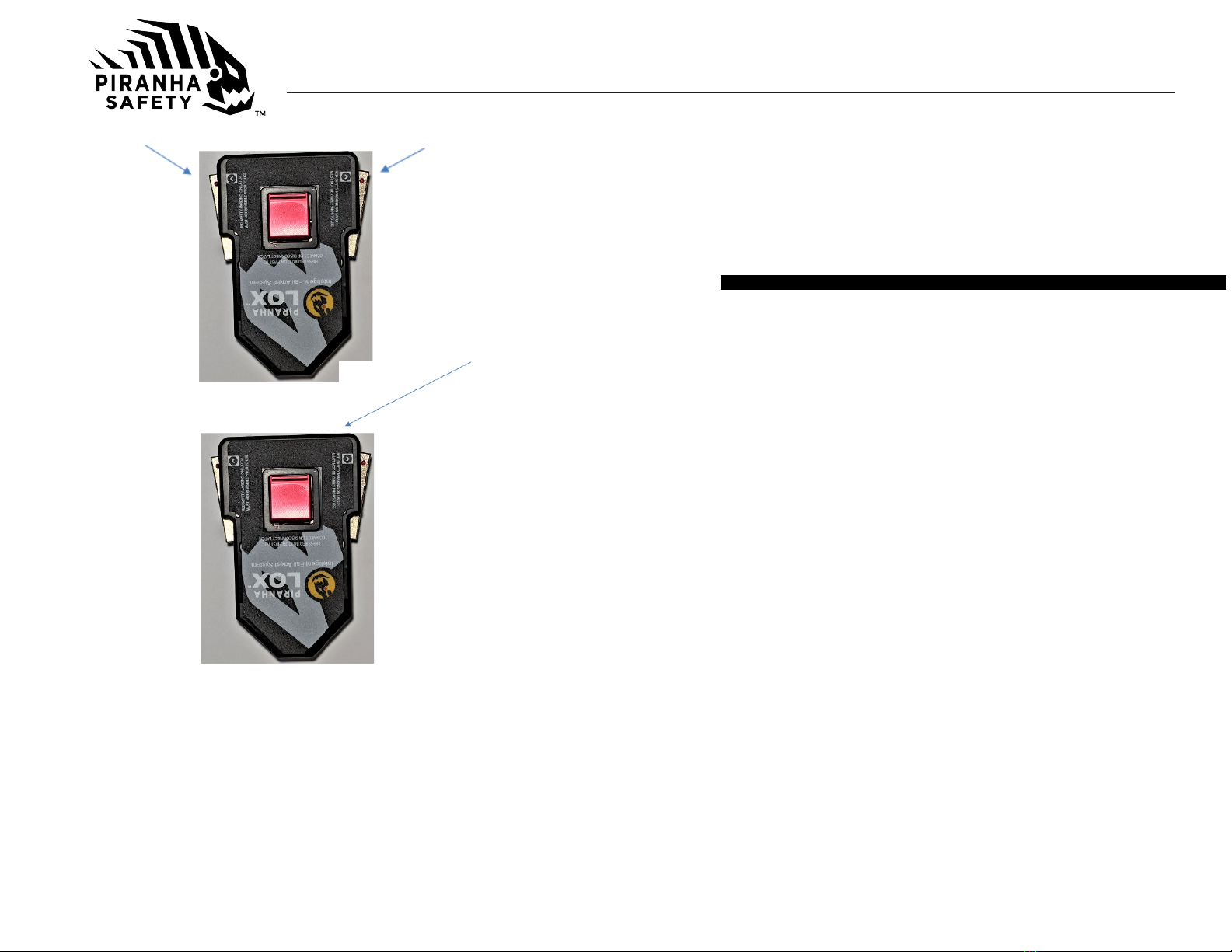

12) IMPACT FORCES:

Any SRL that has been subjected to the forces of arresting a fall

must be immediately removed from service and marked as

“UNUSABLE” until recertified or replaced. RELIANCE/PIRANHA-

SAFETY SRL’s have impact load indicators built into the anchorage

component on top of the SRL that facilitate inspection for fall

loading.

IMPORTANT: When working with tools,

materials, or in high temperature

environments, ensure that associated fall protection equipment can

withstand high temperatures, or provide protection for those items.

Page 13