Pitco Frialator, Inc.,P.O. Box 501, Concord, NH 03302-0501 x1509 Route 3A, Bow NH 03304, USA

Phone (603) 225-6684 xFax (603) 225-8472 xwww.pitco.com

L10-129 Rev 4(02/07)

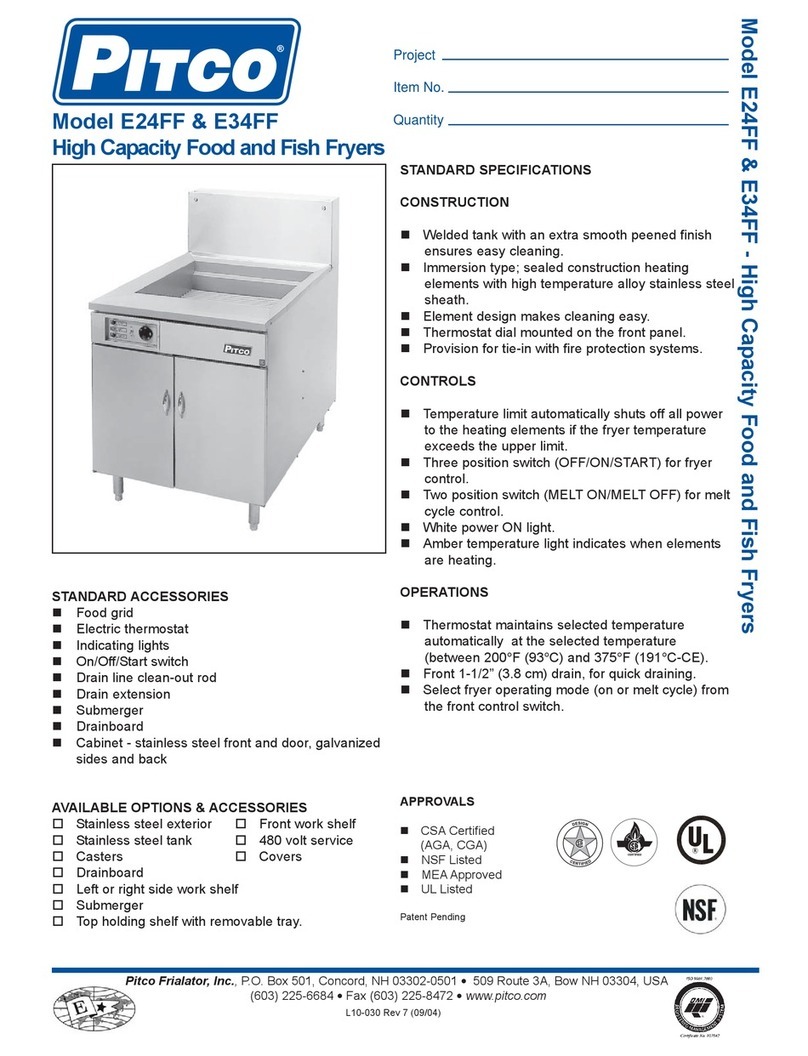

Model SG14T

Tube Fired Gas Fryer

Project __________________________

Item number _____________________

Quantity _________________________

APPROVALS

CSA Certified

(AGA, CGA)

NSF Listed

MEA Approved

CE Certified

Australian Gas Assoc.

Certified (AuGA)

Patent Pending

Model SG14T

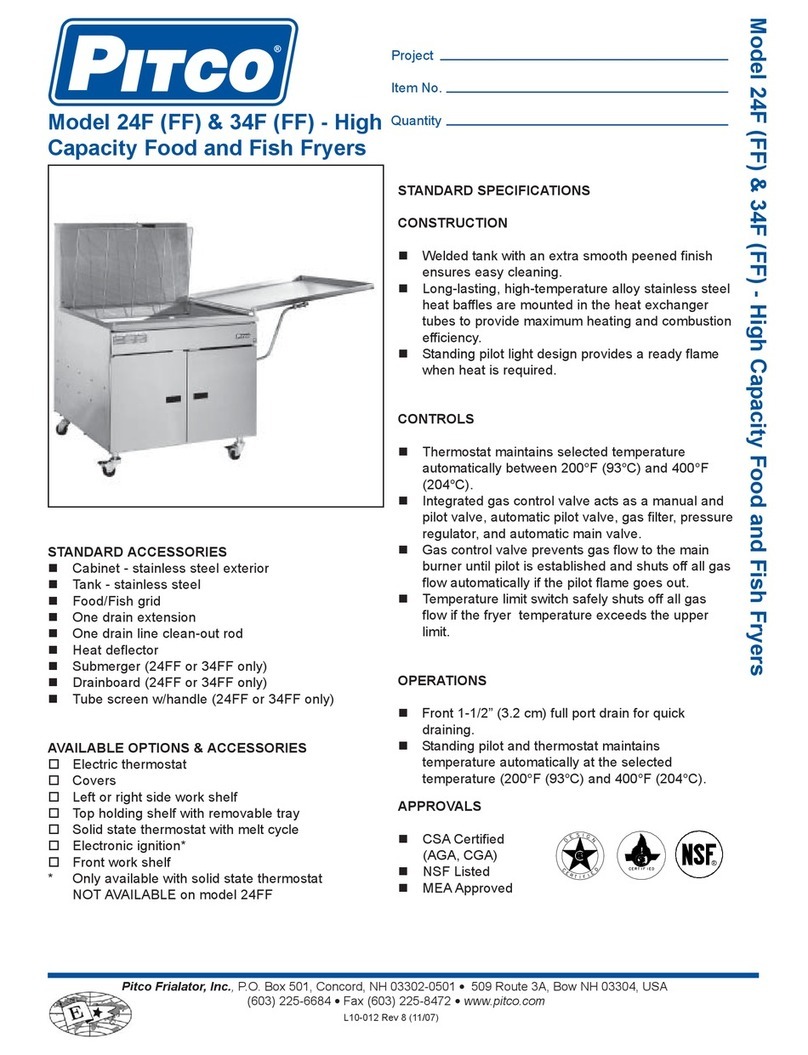

STANDARDACCESSORIES

Two nickel-plated, oblong, wire mesh baskets

Two nickel-plated tube racks

One drain extension

One drain line clean-out rod

Fryer cleaner sample

Rear gas connection

Manual gas shutoff

Two 1 1/4” (3.2 cm) full port drain valves

Built-in integrated flue deflector

Removable basket hanger for easy cleaning

9” (22.9 cm) adjustable legs

Cabinet - stainless steel front, door, and sides

Tank - mild steel

AVAILABLE OPTIONS &ACCESSORIES

Stainless steel tank

Stainless steel back

9” (22.9 cm) adjustable casters

Covers

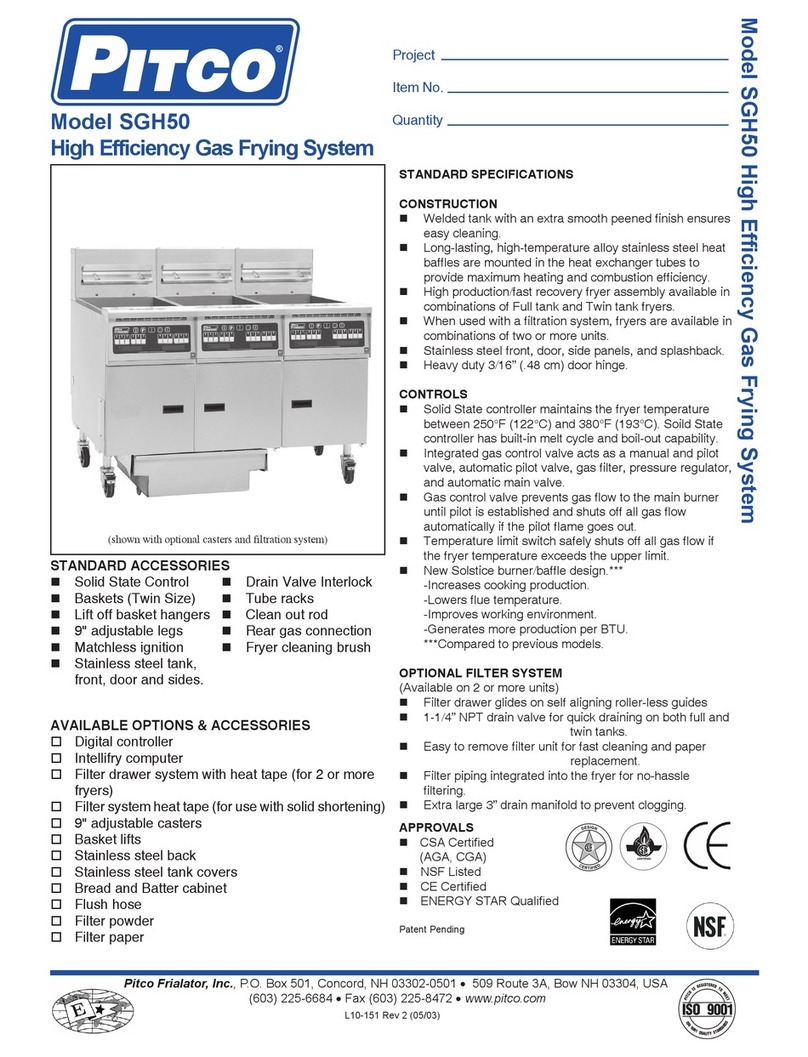

STANDARD SPECIFICATIONS

CONSTRUCTION

Seperate welded tank design.

Welded tank with an extra smooth peened finish ensures

easy cleaning.

Long-lasting, high-temperature alloy stainless steel heat

baffles are mounted in the heat exchanger tubes to provide

maximum heating and combustion efficiency.

Standing pilot light design provides a ready flame when heat

is required.

Stainless steel front, door, side, and splashback.

Heavy duty 3/16” (.48 cm) door hinge.

CONTROLS

Millivolt thermostat maintains selected temperature

automatically between 200qF (93qC) and 400qF (190qC-CE).

Integrated gas control valve acts as a manual and pilot valve,

automatic pilot valve, gas filter, pressure regulator, and

automatic main valve.

Gas control valve prevents gas flow to the main burner until

pilot is established and shuts off all gas flow automatically if

the pilot flame goes out.

Temperature limit switch safely shuts off all gas flow if the

fryer temperature exceeds the upper limit.

New Solstice burner/baffle design.***

-Increases cooking production.

-Lowers flue temperature.

-Improves working environment.

-Generates more production per BTU.

***Compared to previous models.

OPERATIONS

Two front 1 1/4” (3.2 cm) full port drains for quick draining.

9” (22.9 cm) clearance allows for ease of cleaning.