Page 2 For technical questions, please call 1-888-866-5797. Item 64042

Specifications

Rated Capacity 10,000 lb.

IMPORTANT SAFETY INFORMATION

1. Study, understand, and follow all instructions

before operating this device.

2. Wear eye protection that meets ANSI/ISEA Z87.1

and OSHA standards.

3. Do not exceed rated capacity.

4. Make sure setup is stable and secure

before performing any work.

5. Failure to heed these markings may result in

personal injury and/or property damage.

6. No alterations or modifications shall

be made to this product.

7. Keep work area clean and well lit.

8. This product is not a toy. Do not allow

children to play with or near this item.

9. Do not operate when tired or when under the

influence of alcohol, drugs or medication.

10. Avoid moving parts while using the Ram. Once unit

is set in place keep fingers and hands away from

contact areas. If unit needs to be moved, release

pump pressure, move, and resume pumping.

11. Wear heavy-duty work gloves during use.

12. Be aware of dynamic loading!

Sudden load movement may briefly create

excess load causing product failure.

13. Replacement parts and accessories.

When servicing, use only identical replacement

parts. Only use accessories intended for use

with the pull back ram. Approved accessories

are available from Harbor Freight Tools.

14. Store idle equipment. When not in use, the pull

back ram should be stored in a dry location to

reduce rust. For safety, store the pull back ram

in a locked cabinet, out of reach of children.

During long term storage, coat the exposed

chrome area of the ram with a protective lubricant

(such as silicon spray) to prevent rust damage.

15. Keep coupler valves protected when not in use.

Dust caps are included for all coupler

valves and should be screwed in when not

in use to keep the equipment clean.

16. Use as intended only.

17. Inspect before every use; do not use

if parts are loose or damaged.

18. Maintain product labels and nameplates.

These carry important safety information.

If unreadable or missing, contact

Harbor Freight Tools for a replacement.

Assembly

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this document

including all text under subheadings therein before set up or use of this product.

End

Plug

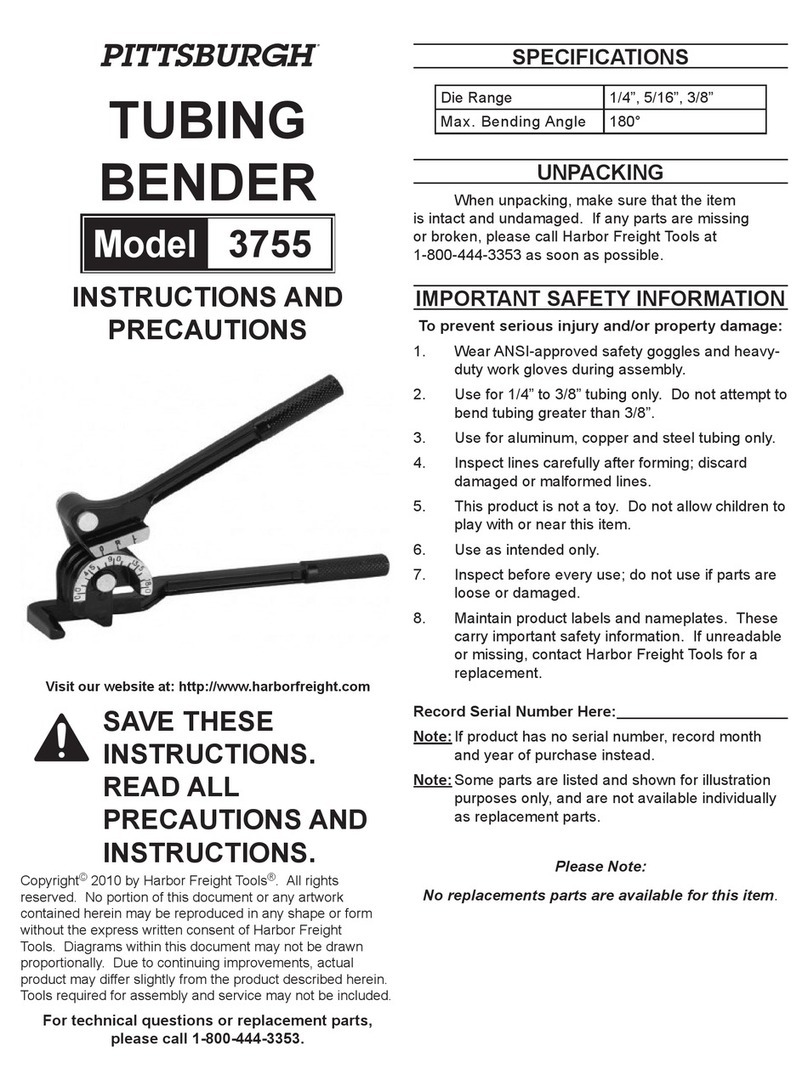

Figure A: Removing End Plug

1. Unscrew and save the End Plug located on the

end of the Coupler as shown in Figure A.

Pump

Hose

Figure B: Connecting Hose

2. Securely screw the Hydraulic Pump Hose (not

included) into the Coupler as shown in Figure B.

3. Refer to the Hydraulic Pump (sold separately)

instruction manual for pump assembly instructions.