Page 2 A05-193-02

Testing and Maintenance

Test DetectorReinstall or

Replace Screen

Check Sensitivity Vacuum and/or Blow-Out

Screen and Chamber

Smoke Detector Maintenance

Nuisance alarms from smoke detectors can be caused by a

number of conditions, but one of the more prevalent is

lack of proper maintenance. Everyday dust, grime, and

moisture can render detectors ineffective or change

sensitivity levels.

Ease of Maintenance

NFPA 72 requires that all smoke detectors shall be visually

inspected in place at least semiannually to identify missing

detectors, detectors with impeded smoke entry,

abnormally dirty detectors, and detectors no longer

suitably located because of occupancy or structural

changes. The standard also goes on to say that a test shall

be performed annually to assure that each smoke detector

is operative and produces the intended response.

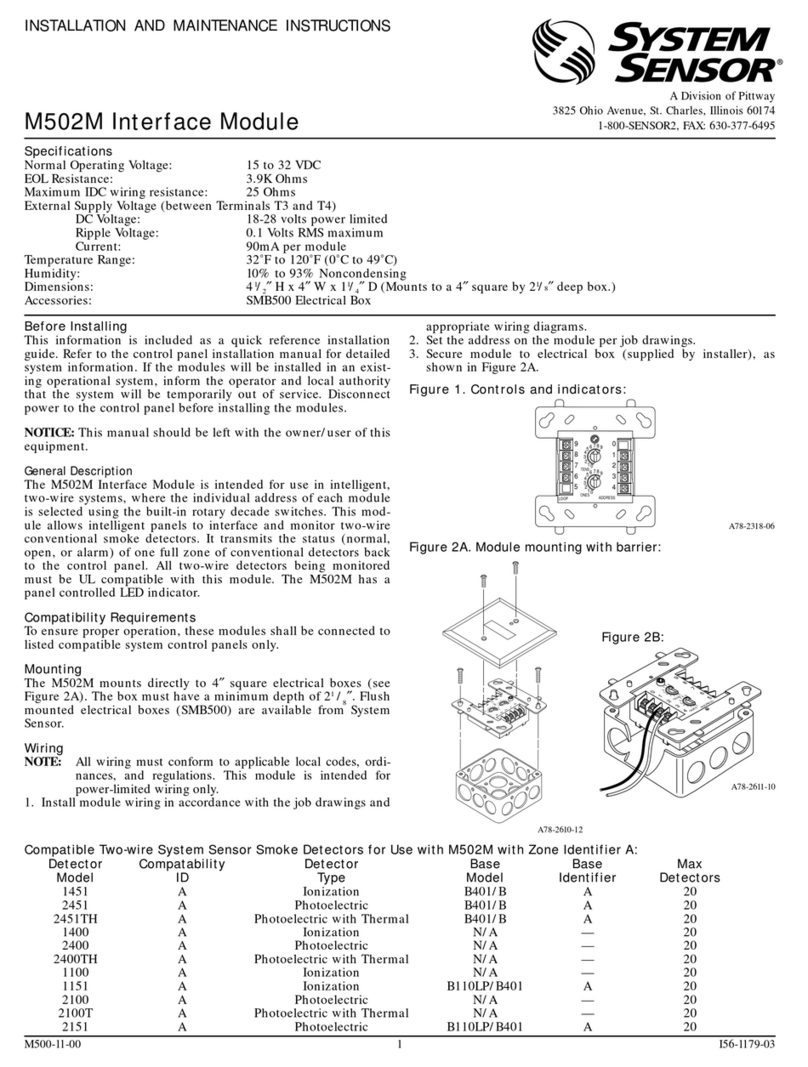

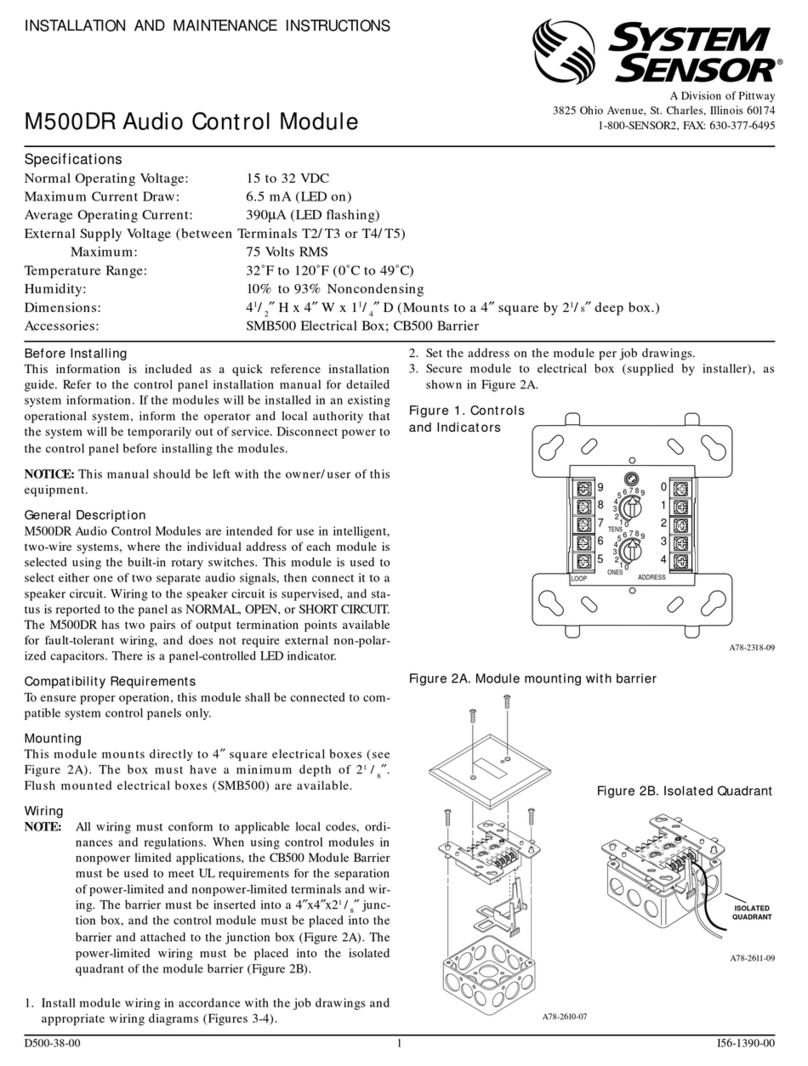

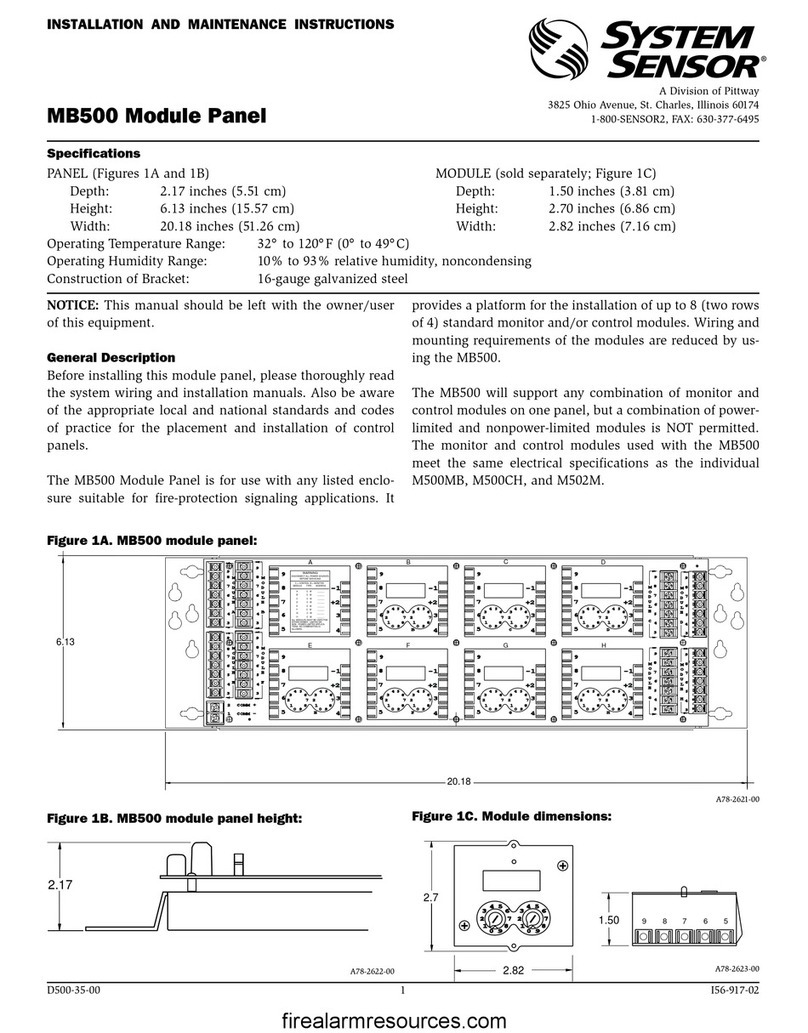

System Sensor detectors have been designed with these

requirements in mind. Detectors may be disassembled

quickly to allow convenient access to the special .020″

(0.5mm) mesh insect screen and chamber.

The screen should be removed and thoroughly cleaned

with a soft brush or vacuum to remove all loose and

excessive dirt buildup. Clean compressed air is

recommended to blow out any remaining debris on the

screen or in the sensing chamber.

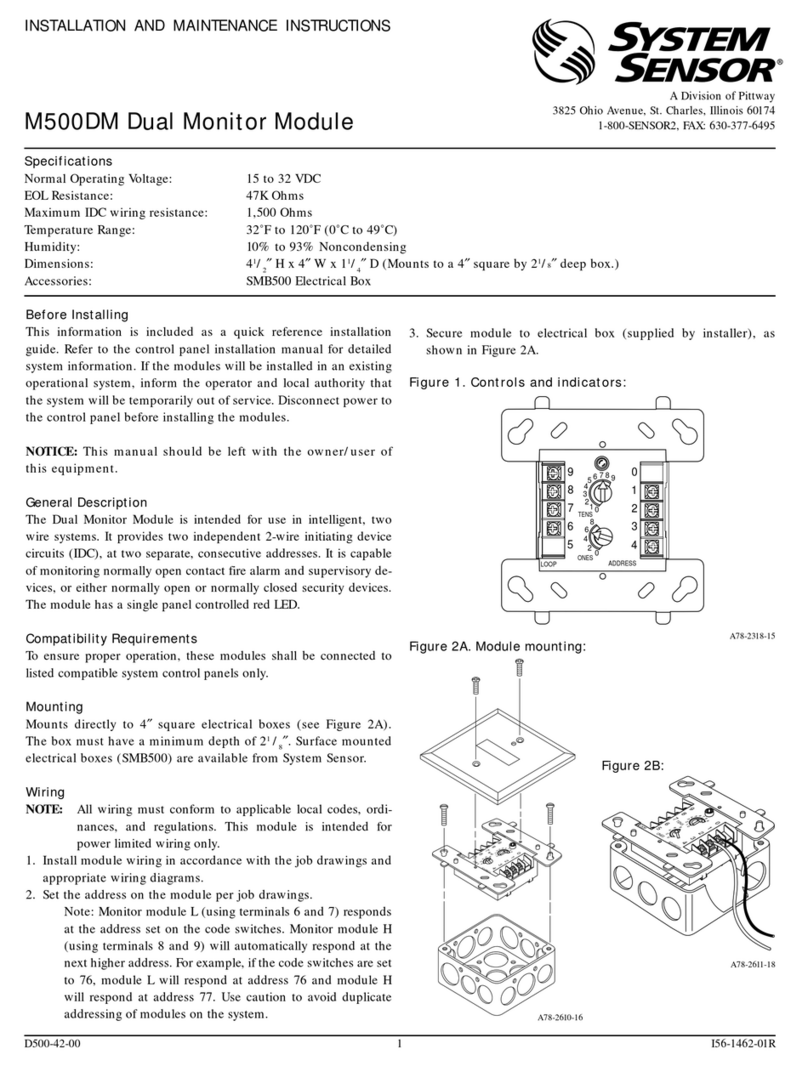

Simple Testing

Test by pushing recessed

switch with any 0.1″maximum

diameter object

Photo unit can be tested

by inserting calibrated

test card and moving

it counterclockwise

into position.

NOTE:

Detector cover

removed

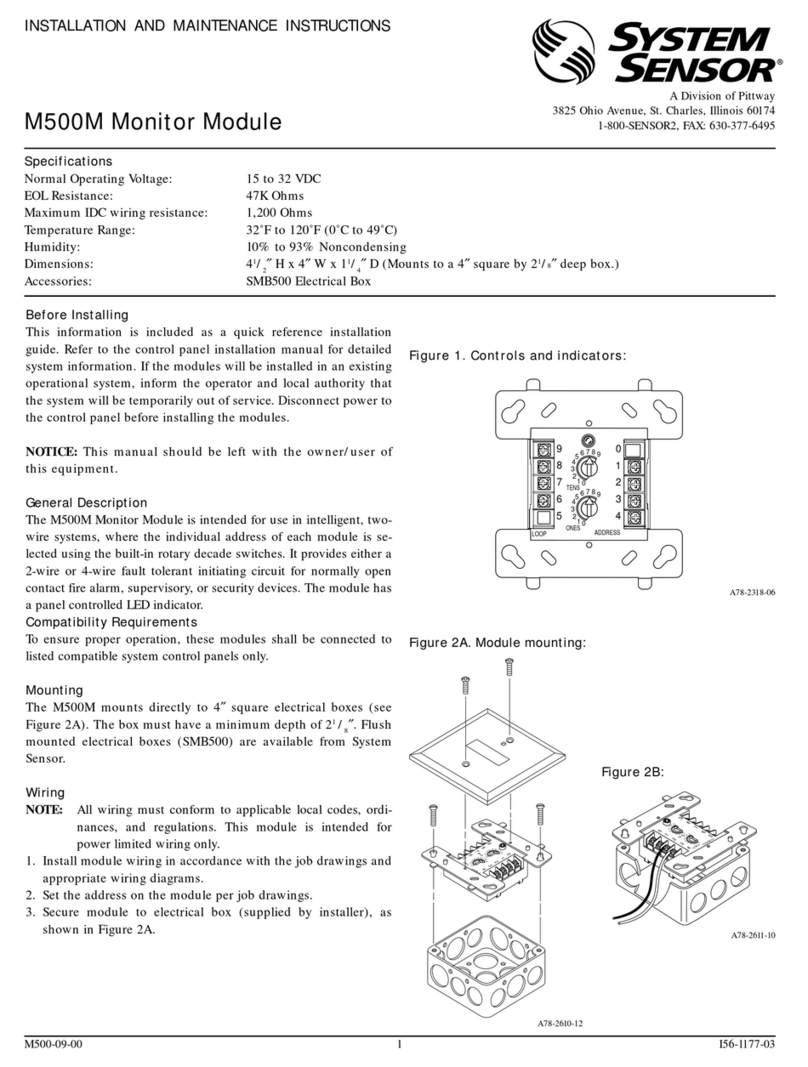

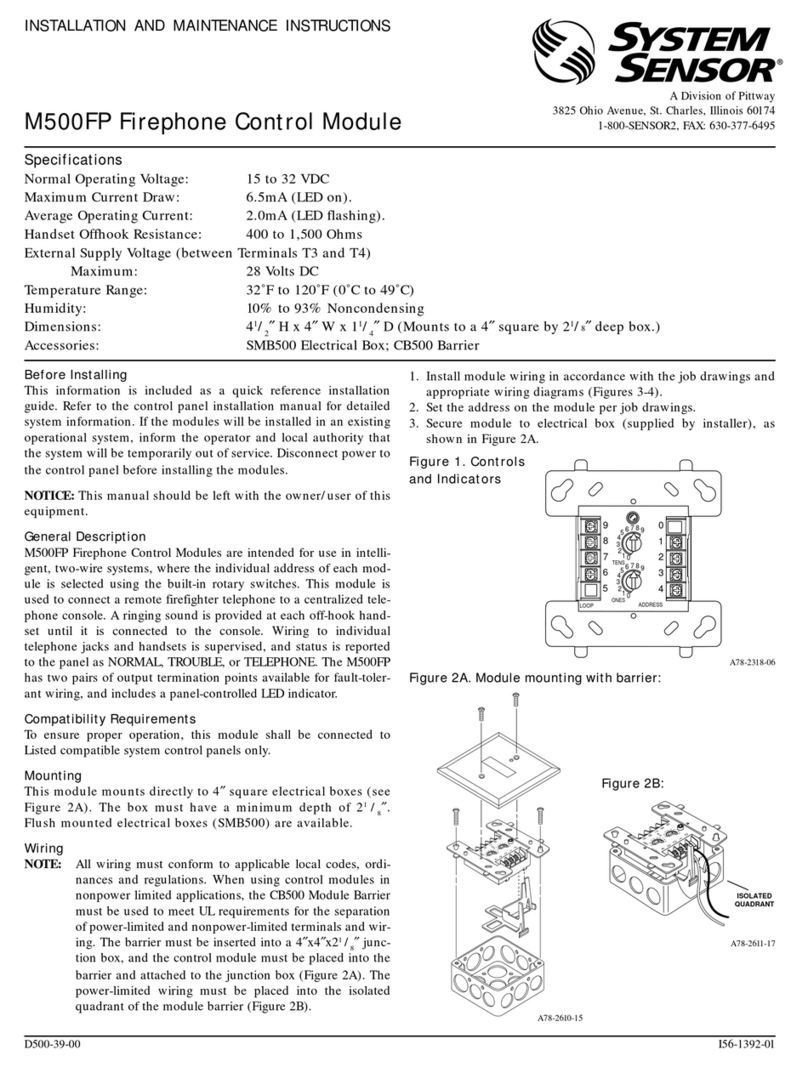

Once cleaned, the detectors must be reinstalled and tested

to insure proper operation of the system. All direct-wire

detectors are equipped with a recessed switch that can be

activated using any 0.1″maximum diameter object. When

the switch is activated, the LED on the detector should

light within 20 seconds to indicate alarm status. Plug-in

detectors (with separate base) incorporate the use of a

magnet test. The 400 Series photo can also be tested with

a calibrated test card. A special slot in the screen housing

allows the test card to be inserted into the chamber. The LED should indicate a latched

alarm condition after 20 seconds when the ALARM end of the card is used; no reaction should occur when tested with

the NO ALARM end.

These built-in test functions are designed to simulate a 3% per foot obscuration level on the ionization units and a

4% per foot obscuration on the photoelectronic units. This is more than sufficient to determine if the detector will

alarm, but is not an adequate way to test and verify a unit’s sensitivity as required by NFPA 72. Instead, use the

MOD400R Sensitivity Test Module to satisfy the NFPA requirement for testing sensitivity.

System Sensor Worldwide Manufacturing & Distribution

In Canada:

Telephone: 905-812-0767

Fax: 905-812-0771

In China:

Telephone: 852-2191-9003

Fax: 852-2736-6580

In the Far East:

Telephone: 852-2191-9003

Fax: 852-2736-6580

In India:

Telefax: 91-022-8202564

In Italy:

Telephone: 39-40-9490-111

Fax: 39-40-382137

In the United Kingdom:

Telephone: 44-1403-276500

Fax: 44-1403-276501