D500-38-00 2 I56-1390-00

© System Sensor 1999

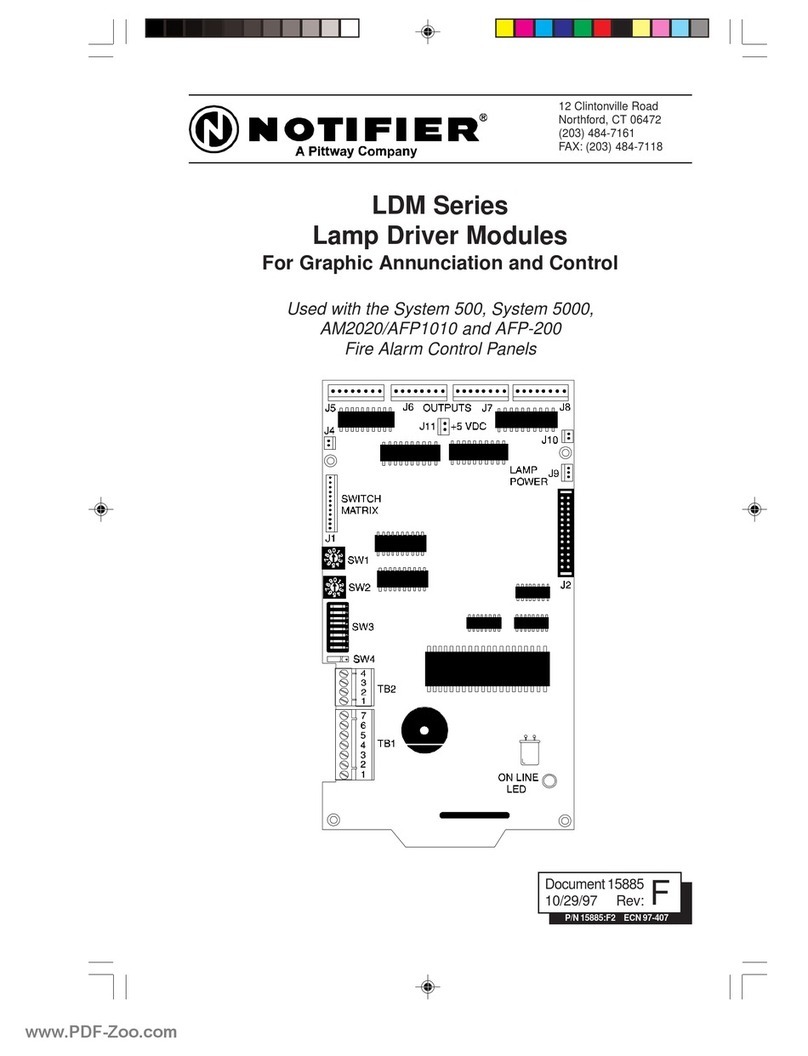

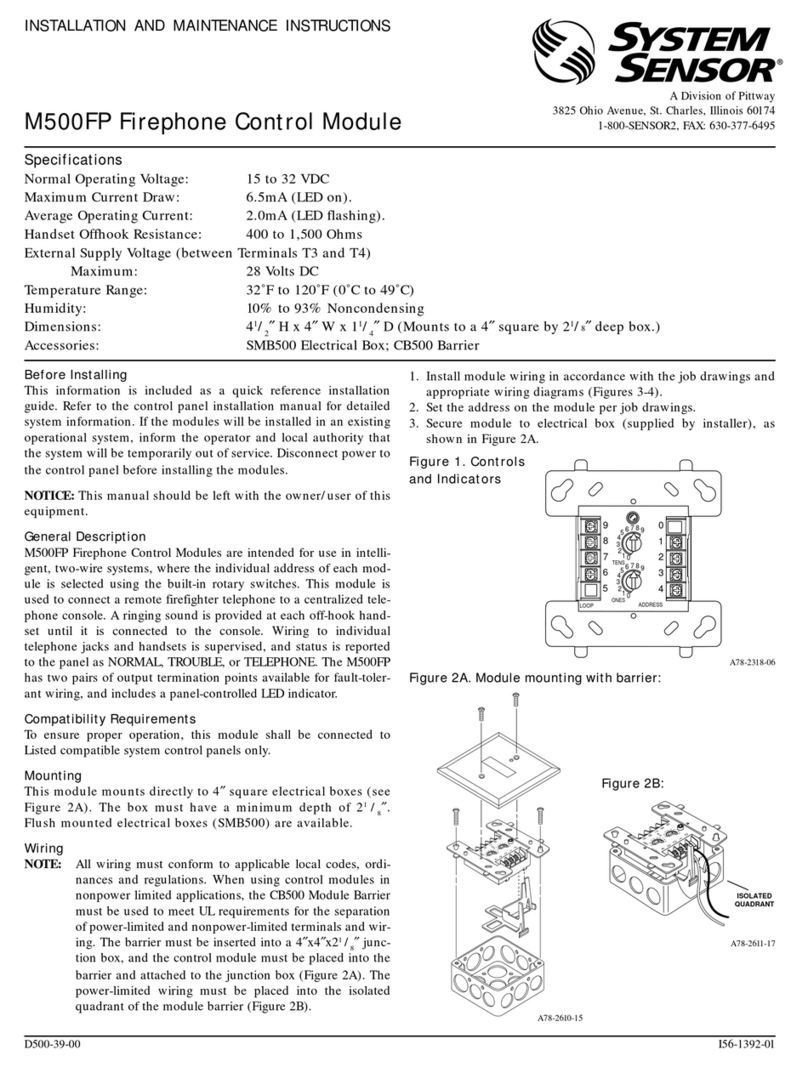

Figure 3. Typical wiring for speaker supervision and switching, NFPA Style Y;

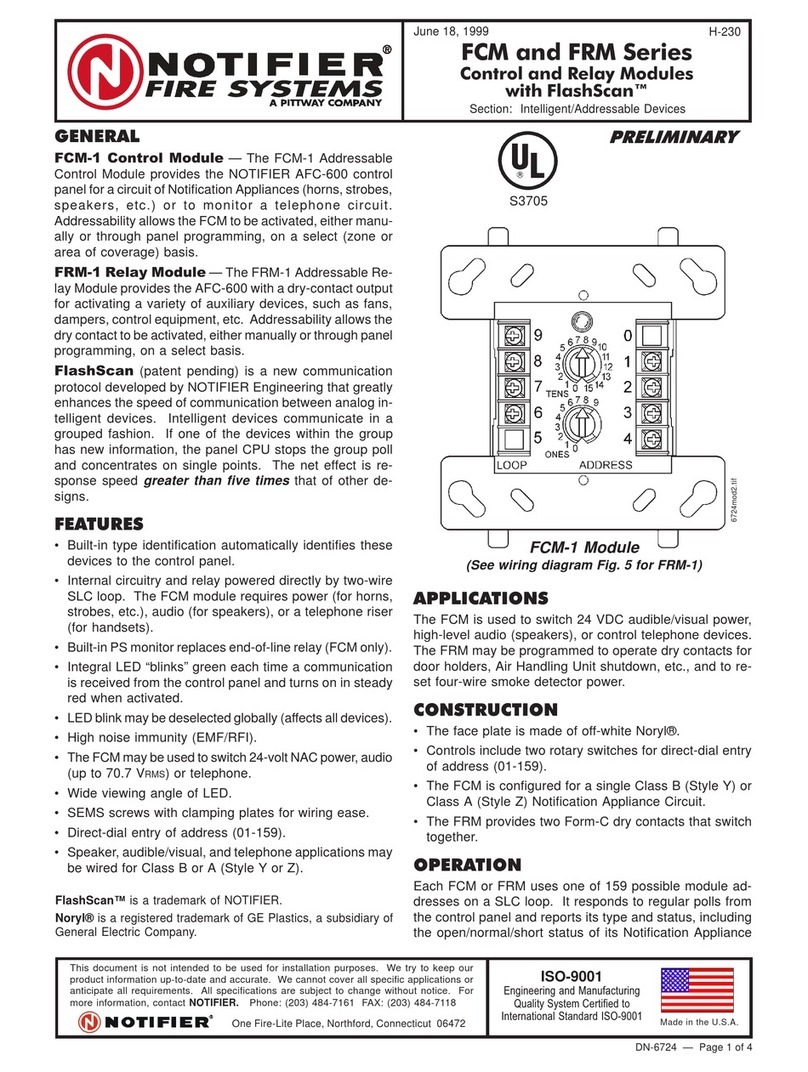

Figure 4. Typical wiring for speaker supervision and switching, NFPA Style Z;

WARNING

All relay switch contacts are shipped in the standby state (open) state, but may have transferred to the activated (closed) state during

shipping. To ensure that the switch contacts are in their correct state, modules must be made to communicate with the panel before

connecting circuits controlled by the module.

A78-2284-24

A78-2284-25

Three-Year Limited Warranty

System Sensor warrants its enclosed module to be free from defects in ma-

terials and workmanship under normal use and service for a period of

three years from date of manufacture. System Sensor makes no other ex-

press warranty for this module. No agent, representative, dealer, or em-

ployee of the Company has the authority to increase or alter the

obligations or limitations of this Warranty. The Company’s obligation of

this Warranty shall be limited to the repair or replacement of any part of

the module which is found to be defective in materials or workmanship

under normal use and service during the three year period commencing

with the date of manufacture. After phoning System Sensor’s toll free

number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: System Sensor, Repair Depart-

ment, RA #__________, 3825 Ohio Avenue, St. Charles, IL 60174. Please

include a note describing the malfunction and suspected cause of failure.

The Company shall not be obligated to repair or replace units which are

found to be defective because of damage, unreasonable use, modifica-

tions, or alterations occurring after the date of manufacture. In no case

shall the Company be liable for any consequential or incidental damages

for breach of this or any other Warranty, expressed or implied whatsoever,

even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or conse-

quential damages, so the above limitation or exclusion may not apply to

you. This Warranty gives you specific legal rights, and you may also have

other rights which vary from state to state.

FROM PANEL OR

(+)

(—)

TO NEXT

(+)

(—)

DEVICE

(+)

(—)

(—)

(+)

(—)

(+)

TO NEXT MODULE

LAST MODULE MUST RETURN

WIRES FOR SUPERVISION

MODULE POLARITIES ARE

SHOWN IN ALARM

CONNECT MODULES TO LISTED COMPATIBLE

BRANCH CIRCUITS

BREAK WIRE TO ENSURE

SUPERVISION OF CONNECTIONS.

DO NOT LOOP WIRE AROUND TERMINALS.

ALL WIRING SHOWN IS SUPERVISED.

(+)

CONTROL PANELS ONLY

PREVIOUS DEVICE

47 K EOL

RESISTOR

A2143-00

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

COMMUNICATION LINE

(—)

AUDIO AMPLIFIER B

70.7 Vrms MAX.

SPEAKERS MUST BE LISTED FOR FIRE PROTECTION.

RMS LOAD CURRENT NOT TO EXCEED:

0.9 AMPERES (RESISTIVE)

0.7 AMPERES (.35 POWER FACTOR)

WHEN A 70.7V AUDIO AMPLIFIER IS USED, TERMINALS 0 AND 1 ARE POWER LIMITED,

WHILE TERMINALS 2-9 ARE NONPOWER LIMITED. IN THIS CASE THE CB500 BARRIER

IS REQUIRED. OTHERWISE, ALL TERMINAL WIRING IS POWER LIMITED.

THE CB500

INCLUDES A LABEL INDICATING WHICH TERMINALS ARE NONPOWER LIMITED.

THIS LABEL MUST BE PLACED ADJACENT TO THE NAMEPLATE LABEL,

PRESENT ON THE MODULE HOUSING.

AUDIO CIRCUIT WIRING MUST BE TWISTED PAIR AS A MINIMUM.

AUDIO AMPLIFIER A

70.7 Vrms MAX.

(+)

(—)

9

8

7

6

54

3

2

1

0

0

1

2

3

456789

TENS

ONES

ADDRESS

LOOP

0

1

2

3

456789

FROM PANEL OR

(+)

(—)

TO NEXT

(+)

(—)

DEVICE

(+)

(—)

(—)

(+)

(—)

(+)

TO NEXT MODULE

LAST MODULE MUST RETURN

WIRES FOR SUPERVISION

MODULE POLARITIES ARE

SHOWN IN ALARM

CONNECT MODULES TO LISTED COMPATIBLE

BRANCH CIRCUITS

BREAK WIRE TO ENSURE

SUPERVISION OF CONNECTIONS.

DO NOT LOOP WIRE AROUND TERMINALS

ALL WIRING SHOWN IS SUPERVISED.

(+)

CONTROL PANELS ONLY

PREVIOUS DEVICE

EOL RESISTOR

IS INTERNAL AT

TERMINALS 8 & 9

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

COMMUNICATION LINE

(—)

AUDIO AMPLIFIER B

70.7 Vrms MAX.

WHEN A 70.7V AUDIO AMPLIFIER IS USED, TERMINALS 0 AND 1 ARE POWER LIMITED,

WHILE TERMINALS 2-9 ARE NONPOWER LIMITED. IN THIS CASE THE CB500 BARRIER

IS REQUIRED. OTHERWISE, ALL TERMINAL WIRING IS POWER LIMITED.

THE CB500

INCLUDES A LABEL INDICATING WHICH TERMINALS ARE NONPOWER LIMITED.

THIS LABEL MUST BE PLACED ADJACENT TO THE NAMEPLATE LABEL,

PRESENT ON THE MODULE HOUSING.

AUDIO CIRCUIT WIRING MUST BE TWISTED PAIR AS A MINIMUM.

AUDIO AMPLIFIER A

70.7 Vrms MAX.

(+)

(—)

SPEAKERS MUST BE LISTED FOR FIRE PROTECTION.

RMS LOAD CURRENT NOT TO EXCEED:

0.9 AMPERES (RESISTIVE)

0.7 AMPERES (.35 POWER FACTOR)

9

8

7

6

54

3

2

1

0

0

1

2

3

456789

TENS

ONES

ADDRESS

LOOP

0

1

2

3

456789