D500-35-00 2 I56-917-02

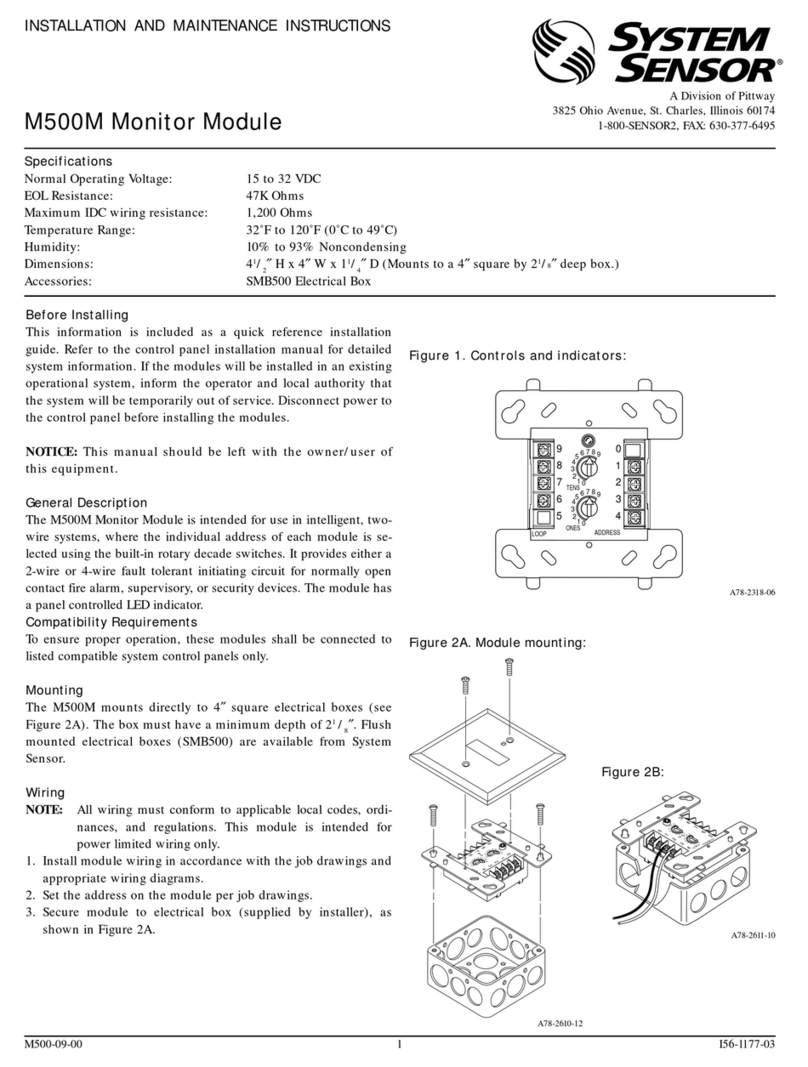

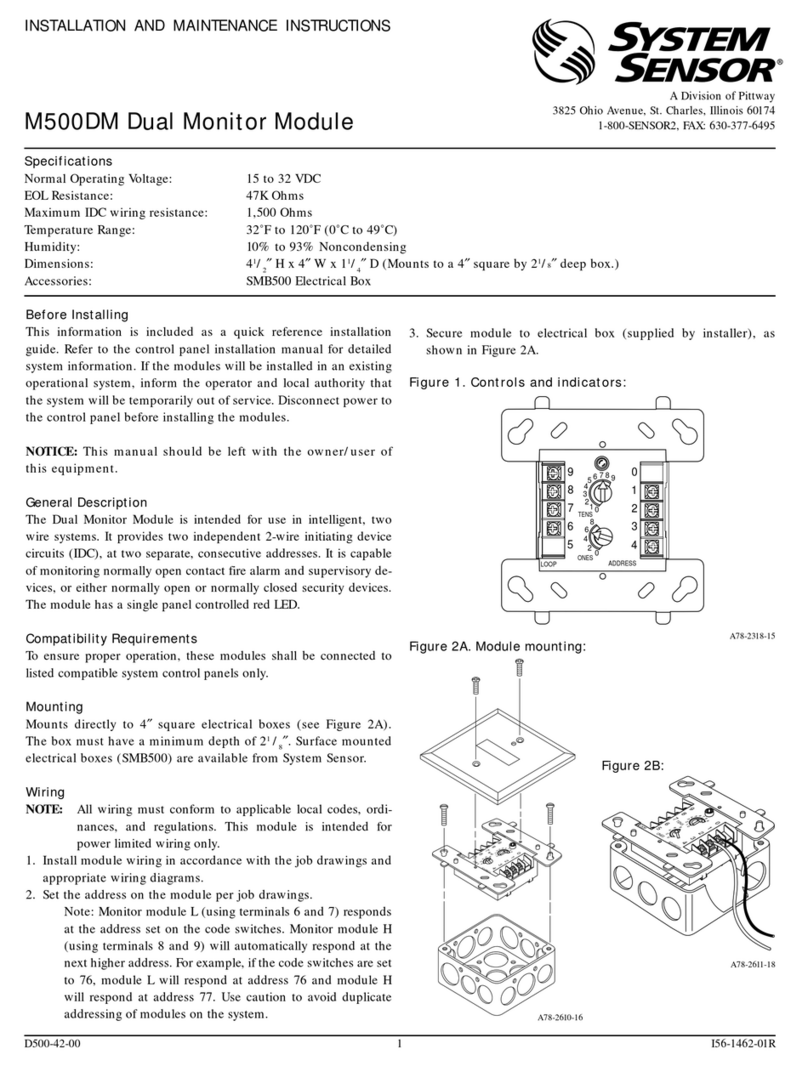

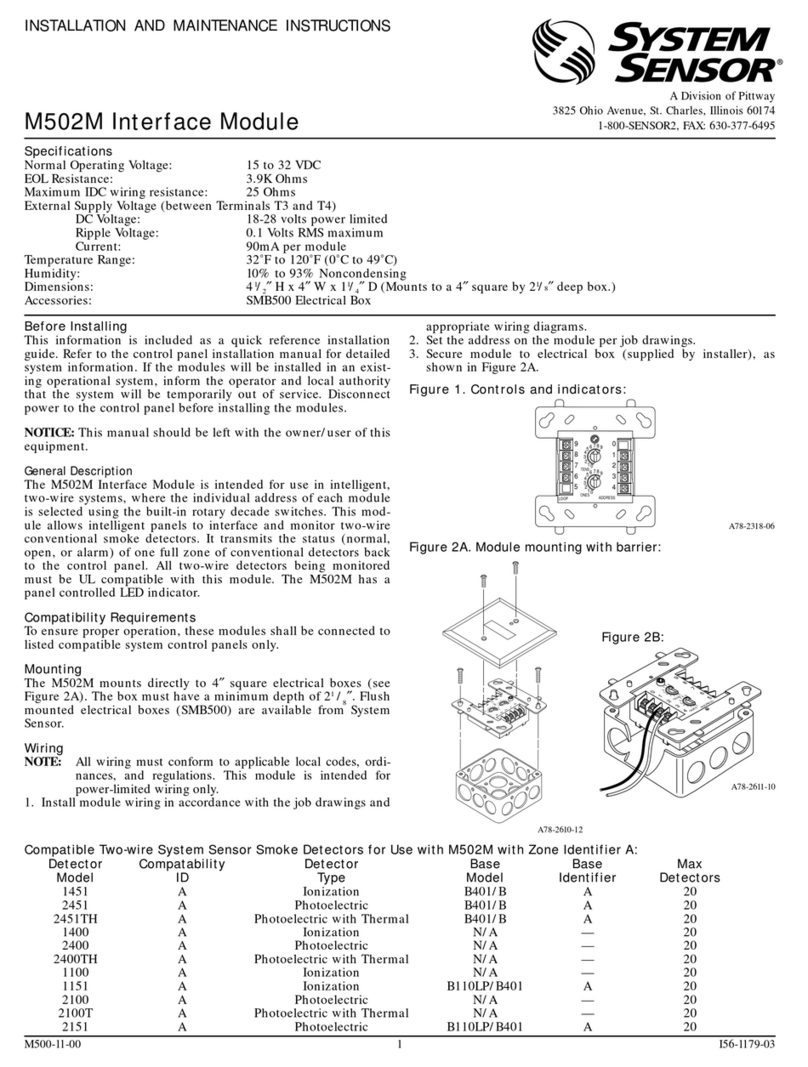

Mounting

1) Select the desired mounting location in a cabinet and

measure the mounting hole centers. The MB500 is

equipped with 3 sets of mounting holes for use depend-

ing on the mounting configuration:

A) 19 inch EIA standard with 18.312 inch (46.5 cm) cen-

ter-to-center mounting holes for horizontal mounting

B) 19.5 inch (49.5 cm) center-to-center mounting holes

for horizontal mounting

C) 5 inch (12.7 cm) center-to-center mounting holes for

vertical mounting

2) Hold the MB500 in place, mark the appropriate set of

mounting holes, and drill holes (if needed) in the

mounting surface.

3) Drive screws in place, allowing room for the MB500 to

slide over the screw heads.

4) Tighten screws to secure the MB500 to the mounting

surface.

WARNING

Remove power before installing modules and wiring the

MB500 panel.

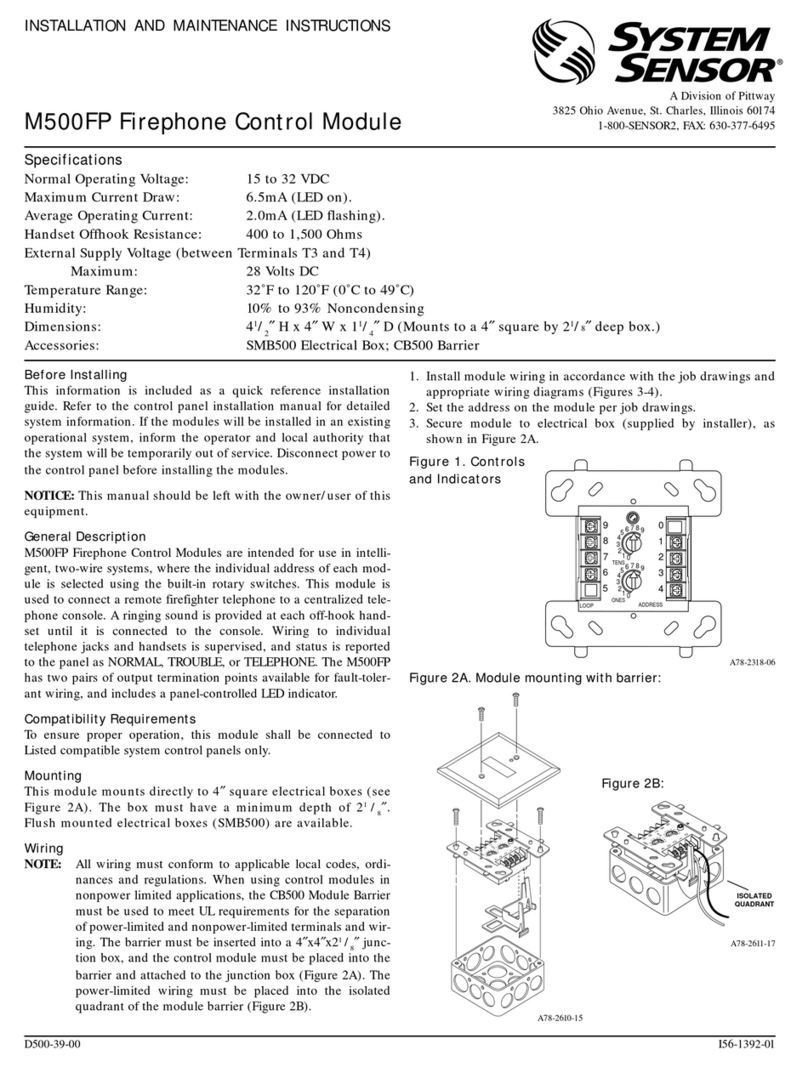

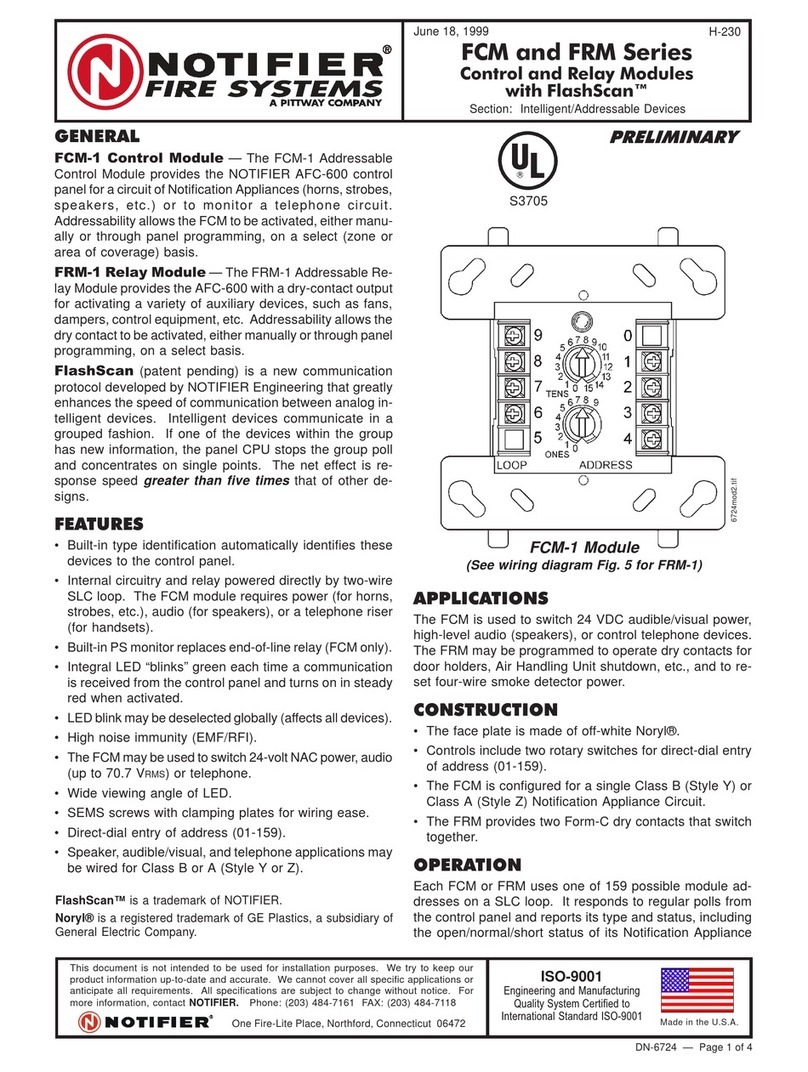

Address Verification

Before installing the modules onto the panel, use the label

in position A (see Figure 3A) to record the type for each

module. Circle C (control) or M (monitor) to indicate the

type of module and record the address on the space pro-

vided.

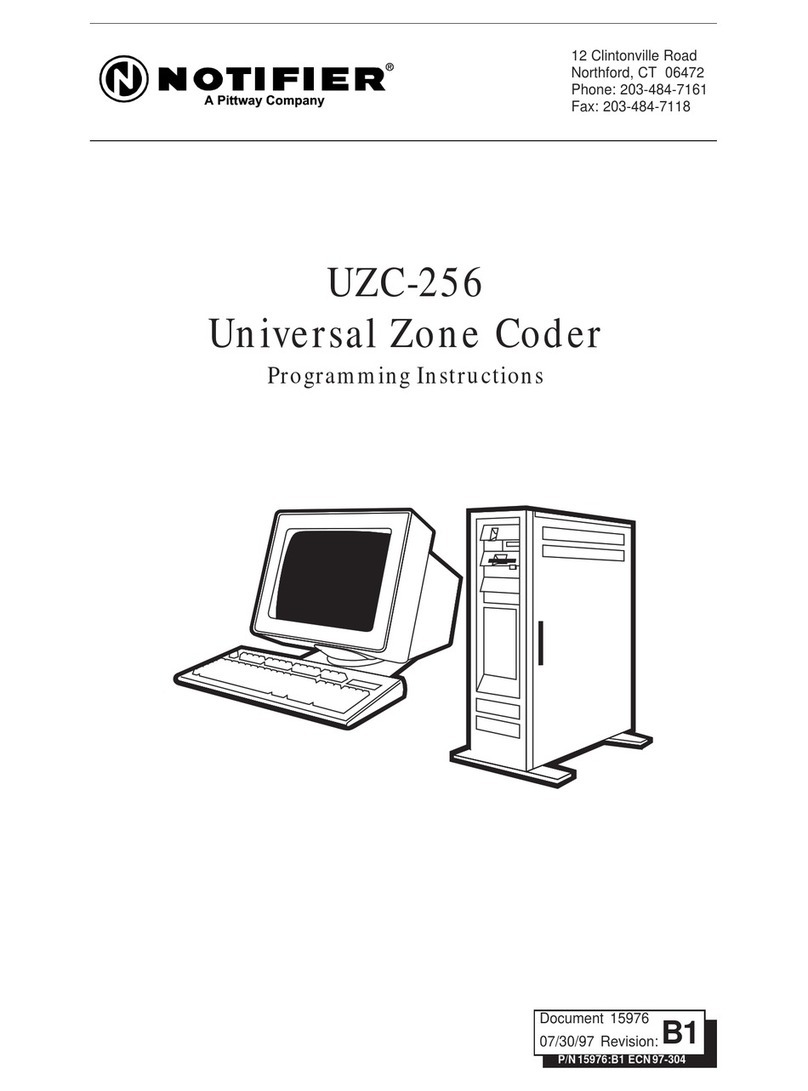

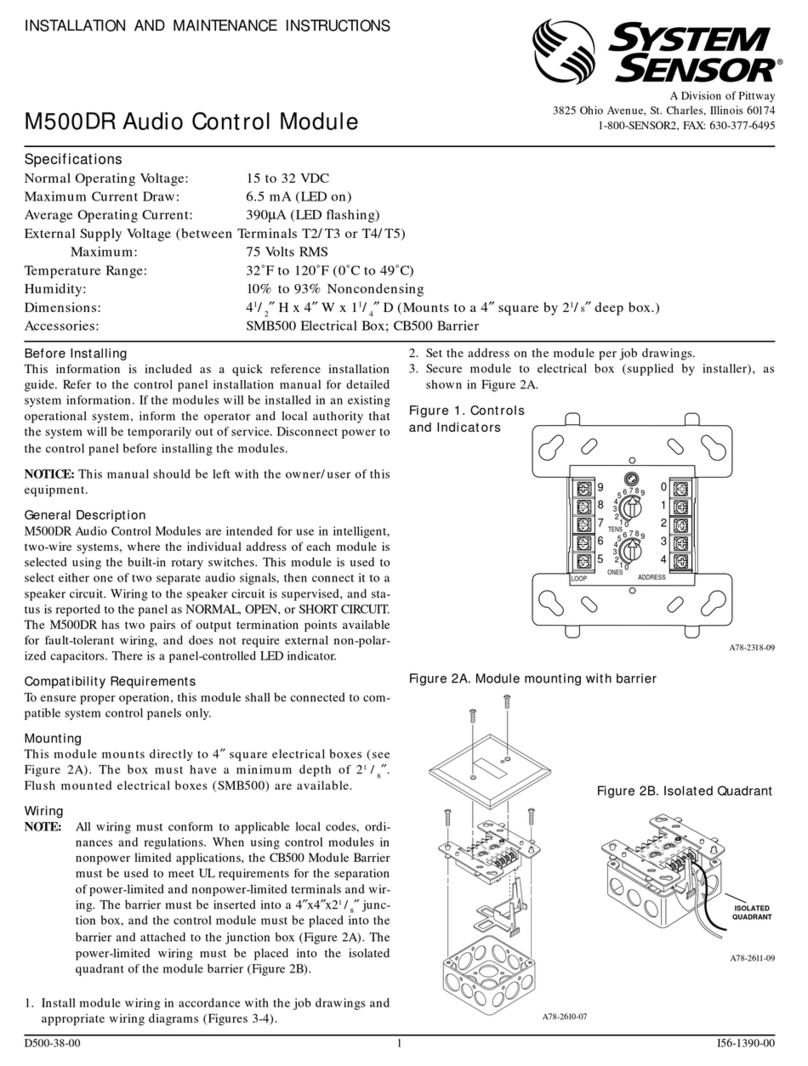

Module Mounting

Before placing the individual modules onto the MB500, re-

move the terminal screws on the modules and break off the

"ears" at the scored section on the module junction box

mounting plate (see Figure 3B). Now the modules can be

plugged into the board. Line up the clips mounted on the

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

4

2 COMM +

1 COMM -

3

E

3

F

4

4

7

5

6

8

9

3

5

6

7

9

8

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

+2

7

5

6

4

3

8

9

-1

7

L

E

U

D

L

E

5

U

6

D

O

MO

M

8

9

BA

3

4

E

L

U

E

5

L

6U

E

9

M

D

OM

D

O

7

8

F G

BC

U

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

4

3

E

G

5

L6

H4

3

E

L

U

5

6

+2

7

5

0 9

6

1

2

4

37

8 1

2

563

4

0 9

3

8

7

54 6

8

9

-1

3

H

D

O7

M8

9

E

C4

5

L

U6

D

O7

D

9

M8M

3

9

D

O

M

7

8

E

D4

5

L

U

O

D

6

7

9

8

ABCD

EFGH

WARNING

DISCONNECT ALL POWER SOURCES

BEFORE SERVICING

C = CONTROL M = MONITOR

MODULE TYPE ADDRESS

A C M ______

B C M ______

C C M ______

D C M ______

E C M ______

F C M ______

G C M ______

H C M ______

ALL MODULES MUST BE USED FOR

EITHER POWER - LIMITED OR

NON - POWER LIMITED APPLICA-

TIONS. NO COMBINATION IS

ALLOWED.

5.000 (C)

18.312 (A)

19.500 (B)

A78-2624-00

Figure 2. Mounting holes:

9

+2

7

5

6

4

3

8

9

-1

7

U

D

O

M

8

9

B

3

4

E

5

L

6U

9

M

D

O

7

8

WARNING

DISCONNECT ALL POWER SOURCES

BEFORE SERVICING

C = CONTROL M = MONITOR

MODULE TYPE ADDRESS

A C M ______

B C M ______

C C M ______

D C M ______

E C M ______

F C M ______

G C M ______

H C M ______

ALL MODULES MUST BE USED FOR

EITHER POWER - LIMITED OR

NON - POWER LIMITED APPLICA-

TIONS. NO COMBINATION IS

ALLOWED.

A

E

Figure 3A. Label each module:

A78-2629-00

A78-2625-00

Figure 3B. Remove module terminal screws and

break off mounting plate ears:

circuit board of the MB500 with the terminals on the indi-

vidual modules, and plug a module into the panel at posi-

tion A (see Figure 4). Repeat the procedure for positions B,

C, and so on, for up to 8 modules.