9

Disassembly

1. Remove the screws (4 pcs) that secure the right-

hand side panel, and take off the panel.

2. Remove the screws that secure the control panel

(2a). Disconnect the cables from the block (2b)

between the oven chambers. Be sure to mark the

cables so they can be fitted back correctly. Discon-

nect the contact (2c) on the lower part of the control

panel.

Now, for each oven chamber (or deck), do the

following:

- Remove the thermostat’s sensor (2d), which is

located inside the oven chamber on the right.To do

this, bend out the fixing clips using a pair of pliers.

Remove the sensor through the hole at the upper-

right lamp socket.

- Remove the screw and then remove the thermal

overload sensor (2e).

- Disconnect the contact (2f) from the lower side

of the circuit board. (Remember, there is one such

contact for each oven chamber or deck.)

- Now take off the control panel.

3. Remove the screws (4 pcs) that secure the left side

panel, and remove the panel.

4. Remove all screws that secure the back panel, and

remove the panel.

5. Remove the screws (2 pcs) that secure the narrow,

front-right side-panel, and remove the panel.

6. Unscrew and remove all the oven-vent knobs.Open

the oven door(s). Remove the screw (1 pc per deck)

that secures the left side of the pillar (6) to the

inside-right of the oven-door frame(s). Now remove

the pillar.

7. Remove the outside screws (2 pcs) that secure the

narrow, front-left side-panel (7).Then, with the oven

door(s) open, remove the screw (1 pc per deck) that

secures the right side of the panel to the inside-left

of the door frame(s).Now remove the panel.

8. Remove the screws from the middle cross-member

(8), and remove the member.

9. Remove the hearth strip (9).

10.Remove the self-tapping screws that fix the indi-

vidual oven decks to each other. Follow the order

described below. (Note that screw quantities are per

deck):

a. – the screws (3 pcs) that secure the front left corner

b. – the screw (1 pc) that secures the back left corner

c. – the screw (1 pc) that secures the back right corner

d. – the screws (6 pcs) that secure the front right

corner.

The decks can now be separated. Lift off each deck

by moving it first backward and then upward.The

oven is now completely disassembled.

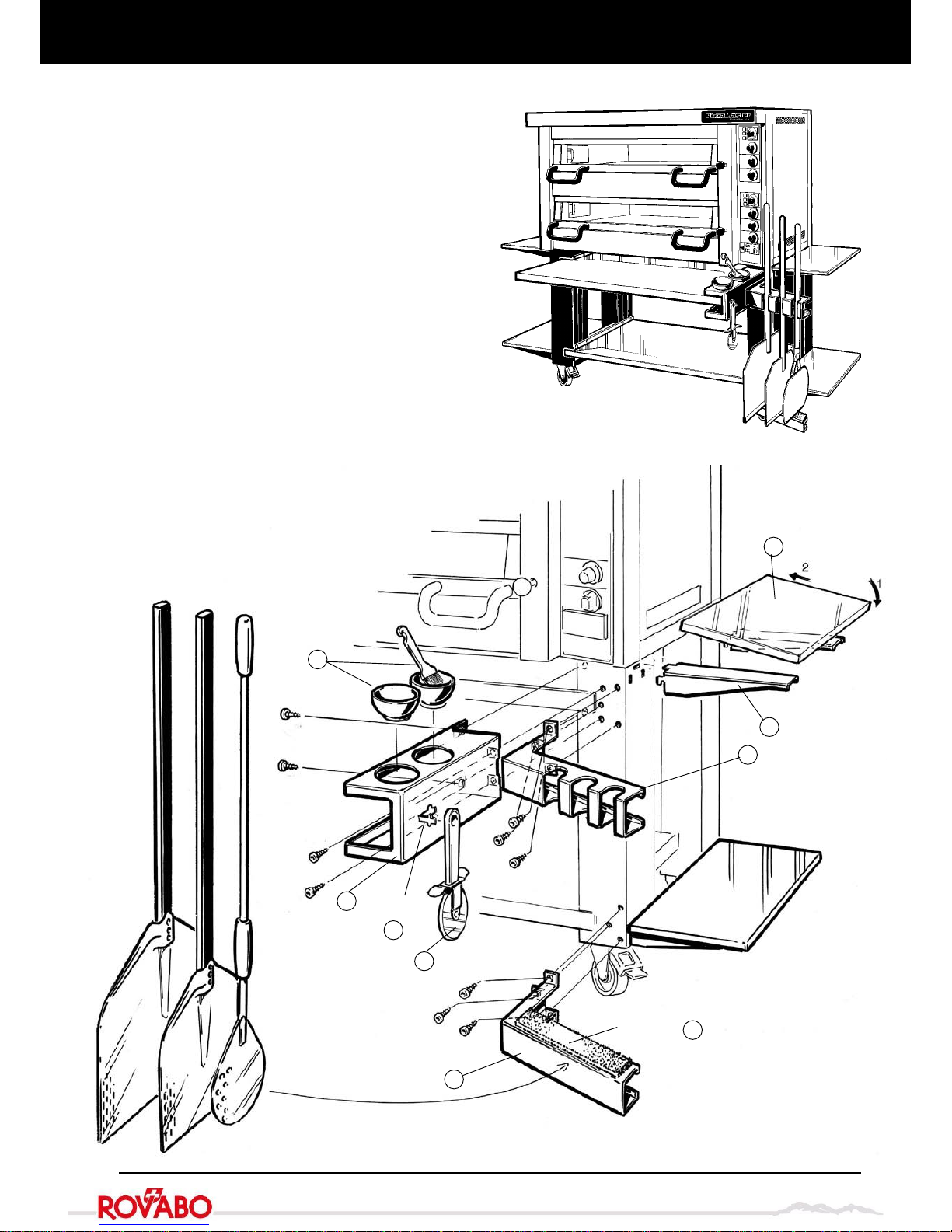

Assembly – Divisible oven

Assembly

Important! Be sure to fit the 2 legs with the lockable

wheels to the front of the oven and the 2 legs with non-

lockable wheels to the back.

11.Lift the lower oven-deck safely and fit the legs using

the M10x30 bolts (12 pcs) + 20x10.5 washers (12

pcs) provided.For each leg, first screw in (but do

not tighten) the internal bolt, i.e. the one that has to

be inserted through the top inside of the leg.Then

screw in the 2 external bolts, but do not tighten.

Finally, tighten the 3 bolts progressively and alter-

nately to fix the leg firmly to the oven.

12.Fit the slide rails (4 pcs) to the legs as shown in the

illustration, using the self-tapping screws provided

(16 pcs).

13.Insert the sliding shelf into either the upper or the

lower pair of rails, as required. (1 sliding shelf is

supplied as standard)

14.Mount the remaining oven decks and secure them in

place using the screws 10 a-d removed at point 10.

15.Fit parts 3-9 using the screws provided.

16.Now, for each oven chamber (or deck):

- Insert the thermostat’s sensor (2d) through the

hole in the upper-right lamp socket.Secure the

sensor in the three fixing clips on the right of the

oven chamber. Fix it into place by bending the fixing

clips using a pair of pliers.

- Fit the thermal overload sensor (2e) as shown in

the illustration, using the screw provided (1 pc).

- Fit the control panel (2a) and secure it in place with

the screws provided.

- Connect the contact (2c) in the lower part of the

control panel to the corresponding contact on the

oven.

- Connect the contact (2f) to the lower side of the

printed circuit board.

- Fit and secure the cables to block (2b).

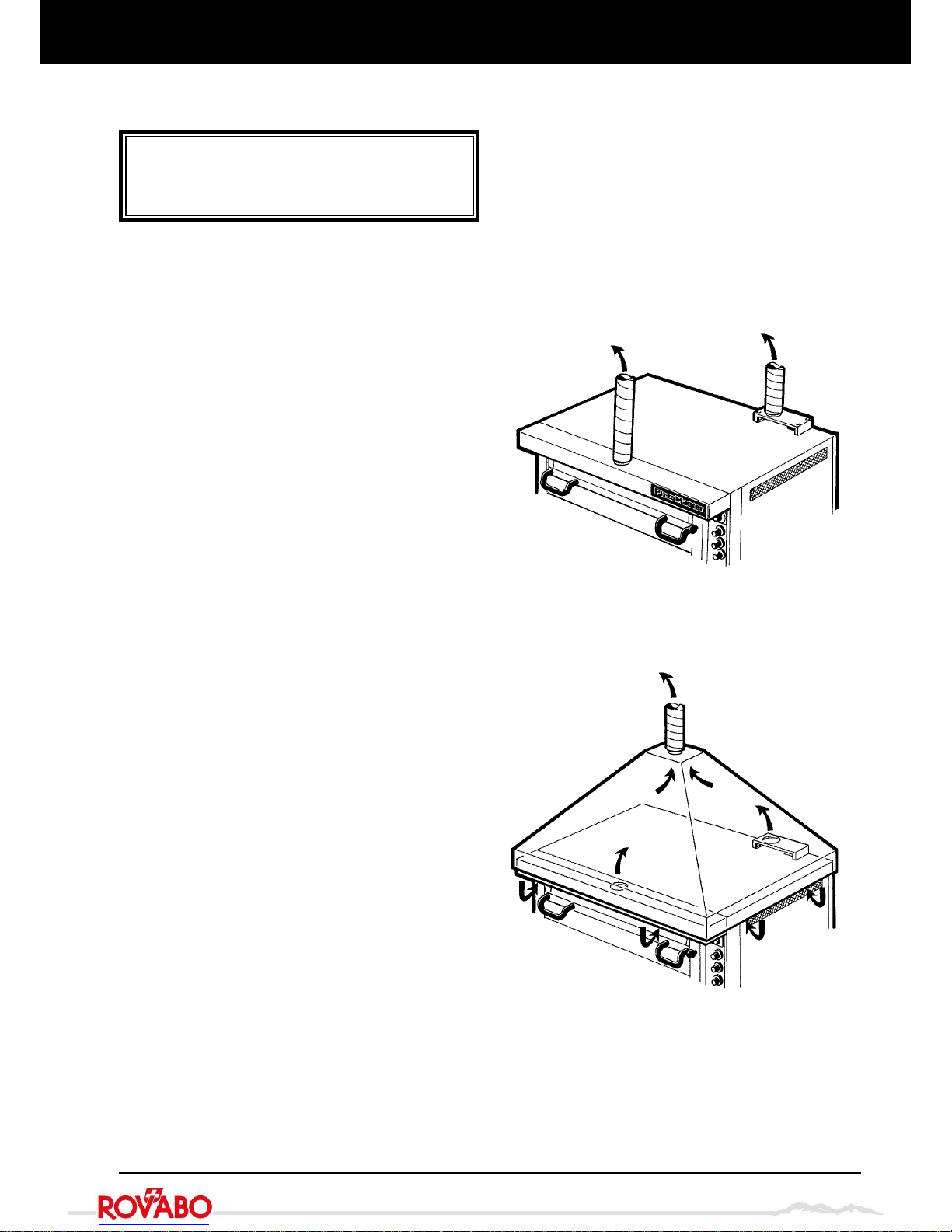

17.Fit the steam duct, using the screws provided (4

pcs).

18.Fit the flue diverter, using the self-tapping screws

provided (4 pcs).

Important! Make sure the open long-side faces

forward.

19.Fit the exhaust outlets (2 pcs).

20.Remove the wooden supports that keep the hearth-

stones in place.

21.Remove all protective plastic film from the oven.

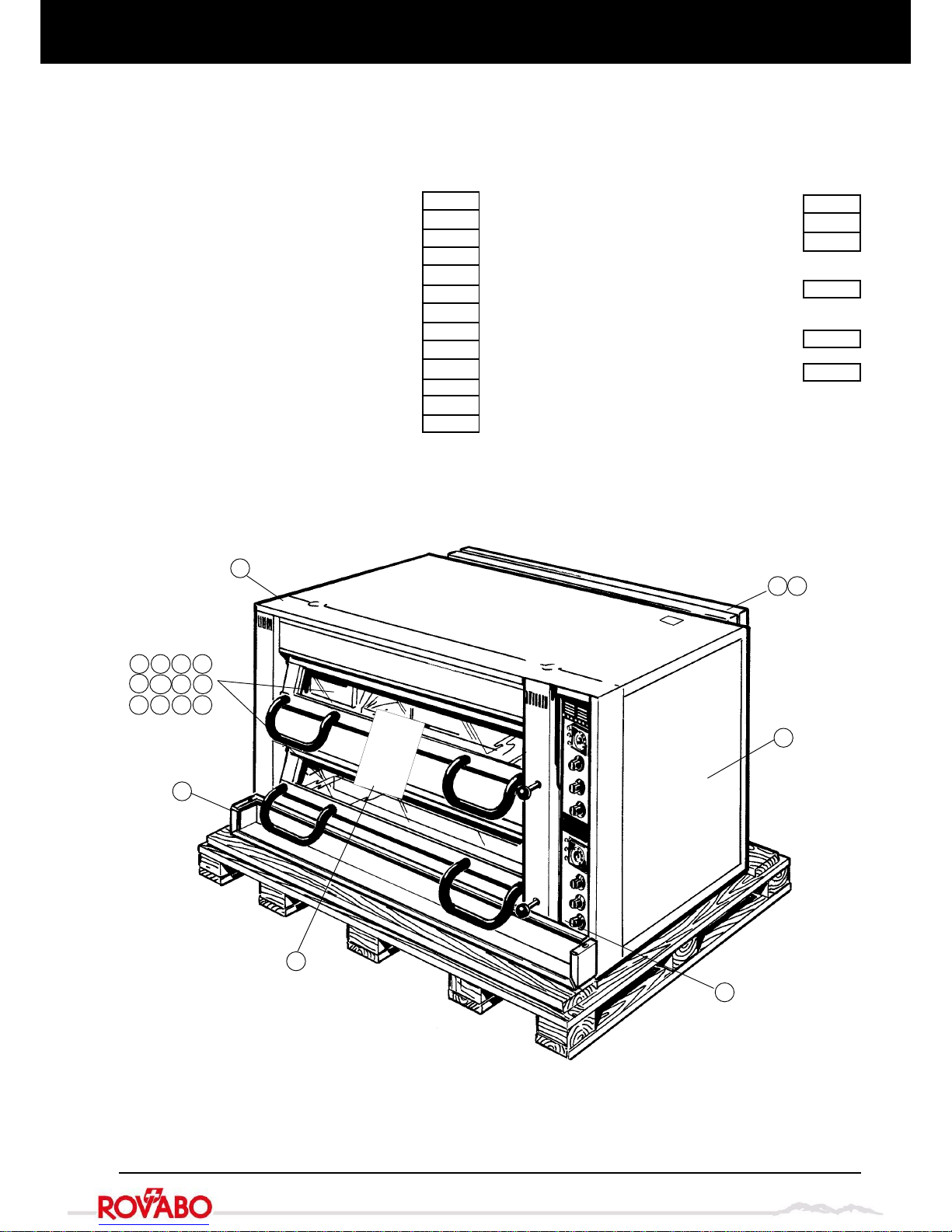

Info!

Weight per oven deck: approx. 150 kg

Important!

Do not remove the wooden supports for the hearth-

stones until you reach point 20 below.

Do not use the oven-door handles or oven-vent

knobs to lift the oven, for it can damage the oven.