2 / 10

© Copyright: All rights reserved. Nothing from this publication may be reproduced, handed over,

co p ied, o r t ran s lated i n t o o t her l a ngua g es, in a ny fo rm o r mean s w ith o ut wr it ten p e rm i ssi on fr om Ply -

moVent A B. Plym oVent AB r e ser ves th e r ig ht to m a ke de s i gn - and tec h n ic a l c hang e s with o ut notic e.

PlymoVent AB, Industrigatan 26,

SE-212 14 Malmö, Sweden

Tel: +46 40 30 31 30, Fax +46 40 30 31 40

www.plymovent.se info@plymovent.se

Factory: PlymoVent AB

P.O. Box 527, SE-921 28 Lycksele, Sweden

Tel: +46 950 57 67 00, Fax +46 950 57 67 90

www.plymovent.se info@plymovent.se

BSAB no: U0.14

Ser.no: DCV

Date: Nov -07

Replace: June -03

TECHNICAL DESCRIPTION

DCV-Controller

DCV-Controller

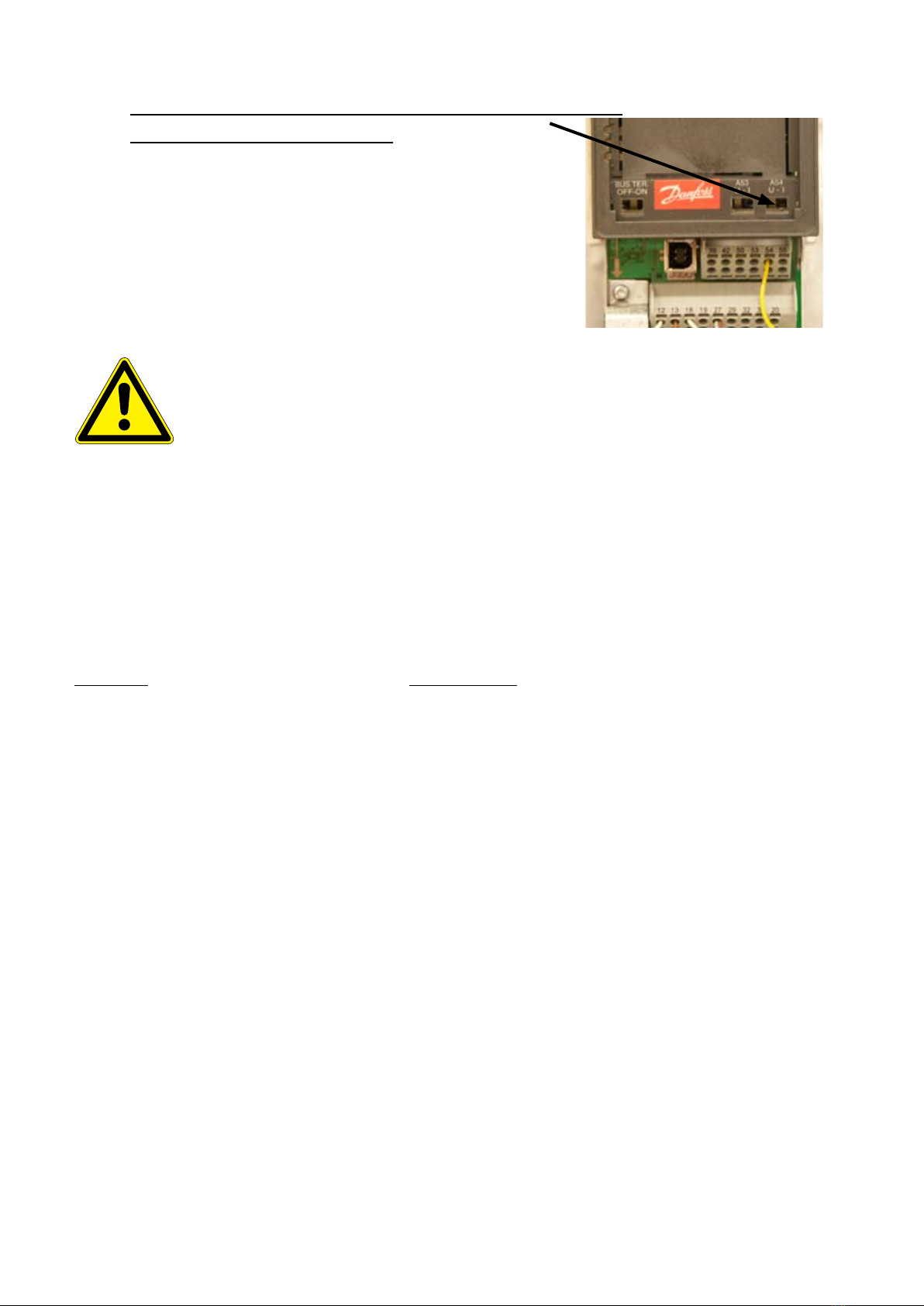

1.1 Frequency Inverter

Model VLT-HVAC

Enclosure IP55

Vibration test 0.7g RMS (IEC-68-2-34/35/36)

Ambient temperature max.50°C

min. 0°C (full operation)

min. -10°C (reduced operation)

Temp. storage/transport -25 °C to 65 °C

Max. altitude above sea 1000 m

Max. relative humidity 93% +2% -3% (storage/transport)

95% non-condensing (operation)

For additional details – consult the inverter handbook.

1.2 Pressure Transmitter

Measuring range 0-1600 Pa (TG-1600)

0-2500 Pa (TG-2500)

0-5000 Pa (TG-5000)

Enclosure IP54

Output signal 4-20 mA

Supply voltage 18 .. 33 VDC

Power Consumption 30 mA

Membrane material LSR (silicon)

Pressure connection 6 mm

Cable connection screw terminals

Linearity < +/- 0.7% fs

Hysteresis < +/- 1% fs

Ambient temperature 0 – 70 °C

Storage temperature -10 – 70 °C

TO ACHIEVE OPTIMUM PERFORMANCE AND

SAFETY, PLEASE READ THE MANUAL CARE-

FULLY!

1 Technical data

Address Tel Fax e-mail

PlymoVent Ltd Marley Way, Southam Rd, 01295 25 93 11 01295 25 17 50 info@plymovent.co.uk

www.plymovent.co.uk Banbury OX16 2RA, England

PlymoVent GmbH Heideweg 24, 02224 97300 02224 89646 info@plymovent.de

www.plymovent.de D-53604 Bad Honnef Germany

PlymoVent SA B.P. 30, Zone Industrielle de Mavault 549 51 55 88 549 51 59 33 info@plymovent.fr

www.plymovent.fr F-86170 Neuville de Poitou, France

PlymoVent Corp. 115 Melrich Road 732 417 0808 732 417 1818 info@plymoventusa.

www.plymovent.com Cranbury, New Jersey 08512, USA

PlymoVent Inc. 24 - 1200 Aerowood Dr. 905 564 4748 905 564 4609 info@plymovent.ca

www.plymovent.ca Mississauga, ON L4W 2S7, Canada