0000101887/071013/A KUA/S EN - 7

KUA-4-S

KUA-2-S

KUA-3-S

© Copyright 2008:All rights reserved.All information within this printed matter may not be reproduced,

handed over, copied, xeroxed or translated into another language in any form or means without written

permission from Plymovent AB.PlymoventAB reserves the right to make design changes.

BSAB no: T0.31

Ser.no: KUA-S/TB

Date: Nov-00

Replace: Sept-97

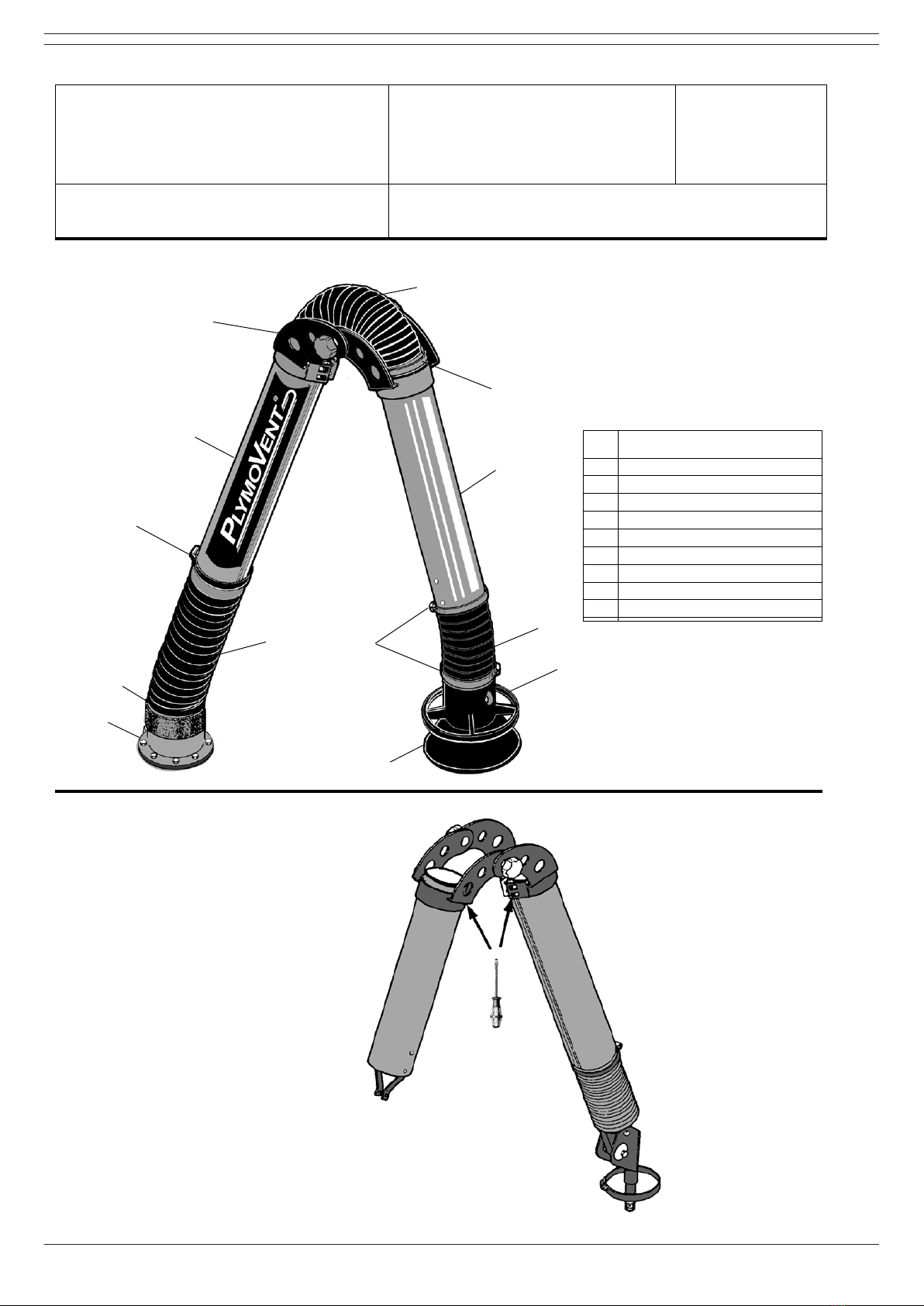

Ball-bearing jointed extraction arm

- Standing (KUA-S)

Components and operation

Hood operation

The black, enamelled ano-dised

metal hood can be angled 110°

forwards, backwards and to the

sides. Large, 360°, ring handle,

Ø300 mm.

Maneuvering

1. Ring handle for positioning

of the hood. Can be reached

from all sides.

2. Damper control knob.

3. Quick-fit catch for simple ex-

change of extension hose and

hood.

KUA - Standing

The PlymoVent ball-bearing jointed extraction arm – KUA-S – is a flexible and

efficient extractor for dust, welding fumes, soldering fumes, oilmist, fumes from

solvents etc. Ideal for many problem areas. The outer and inner arm are coupled

by an externally mounted elbow joint for which we have a patent application pen-

ding. This external joint is adjusted by hand without the need for any tools. The

lower spring-assisted joint supported in a double ball-bearing mount, gives KUA-S

a smooth, flexible movement. The KUA-S reaches above its mounting height and is

manoeuvrable through 360°. Both outer and inner arms are made of light, smooth

aluminium tubing. This not only makes the arm rugged but also minimises the total

weight and noise level, even at high extraction rates.

Delivery

The arm is delivered complete with mounting flange.

Advantages

• Easy to move thanks to the ball-bearing mountings and spring assistance.

• Inner and outer arms made from aluminium tubing give increased

mechanical strength.

• External, middle joint simplies adjustments.

• Easy-to-reach ring handle ensures simple positioning of the hood.

• Standard stanchion for ceiling, oor and wall mounting makes

installation easy.

• Reaches up to 6 m with stanchions PA-110 or PA-220.

• Rugged construction.

TECHNICAL DESCRIPTION

Standing model.

Flange mounted.

2 m, 3 m and 4 m reach.

Flange included.

Max.

working

radius m

Hose

diameter

mm

Recommended

airflow m3/h

2,0

3,0

4,0

160

160

160

800 – 1200

800 – 1200

800 – 1200

Prod.

no.

KUA-2-S

KUA-3-S

KUA-4-S

4. Switch for light cartridge

(see accessories

HL-20/24).

5. Switch for manual start/

stop of fan or damper (see

accessories SA-24, ES-90

or ASE-12).

Technical data

A. Mounting flange

B.Inner arm pivot with friction pad tensioning

adjustment.

C Flame resistant hose made from PVC coated woven

polyamide with internal steel spiral.

DAluminium inner arm.

ETensioned support spring.

F Externally adjustable elbow joint (patent application pending).

GAluminium outer arm.

H Universal joint with hood collar and shut-off damper.

I Hood, constructed from sheet steel, includes safety mesh and

quick-

fit coupling. Hood opening Ø300 mm. 360° ring handle Ø300mm.