3

SPECIFICATIONS

MODEL

NO.

MAX.

OPERATION

TORQUE

Nm

SQUARE

DRIVE

”

MEASURED

TORQUE

Nm

LENGTH

mm

7314-2030 30 1/4 1.5~30 390

7338-2135 135 3/8 6.8~135 410

7312-2200 200 1/2 10~200 520

7312-2340 340 1/2 17~340 640

ALL MODELS

Accuracy *1 CW: ±2% CCW: ±3%

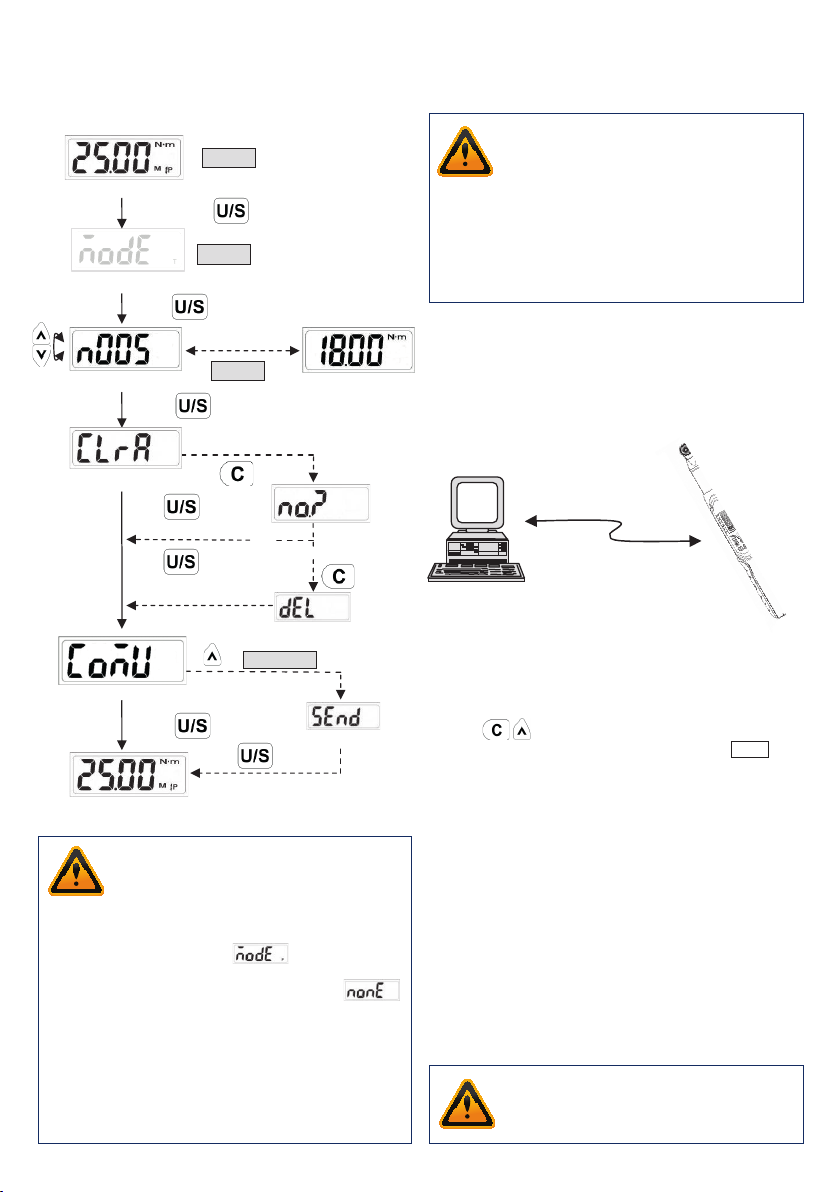

Data memory size 50

PC connectivity *2 No

Pre-setting no. 9 sets

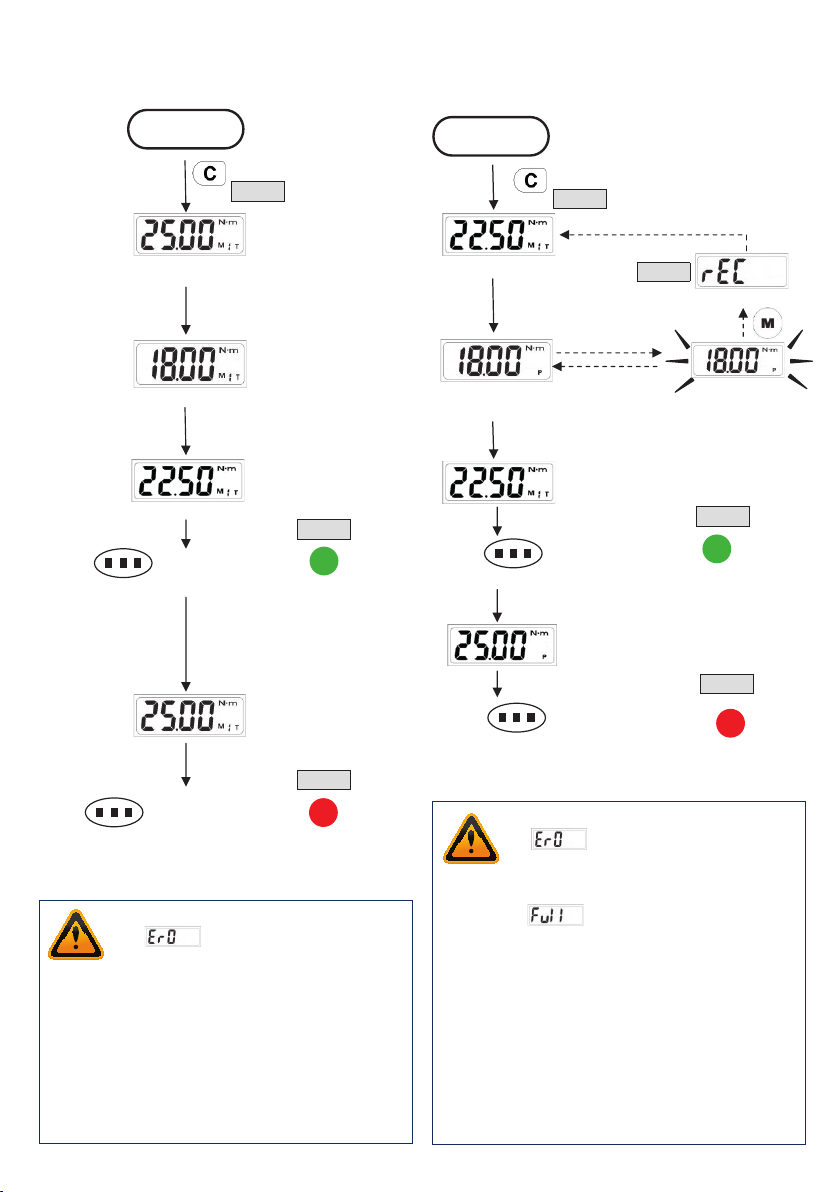

Operation mode Peak Hold / Track

Bright LED 12 LED

(2 red + 10 green)

Unit selection Nm, ft-lb, in-lb, kg-cm

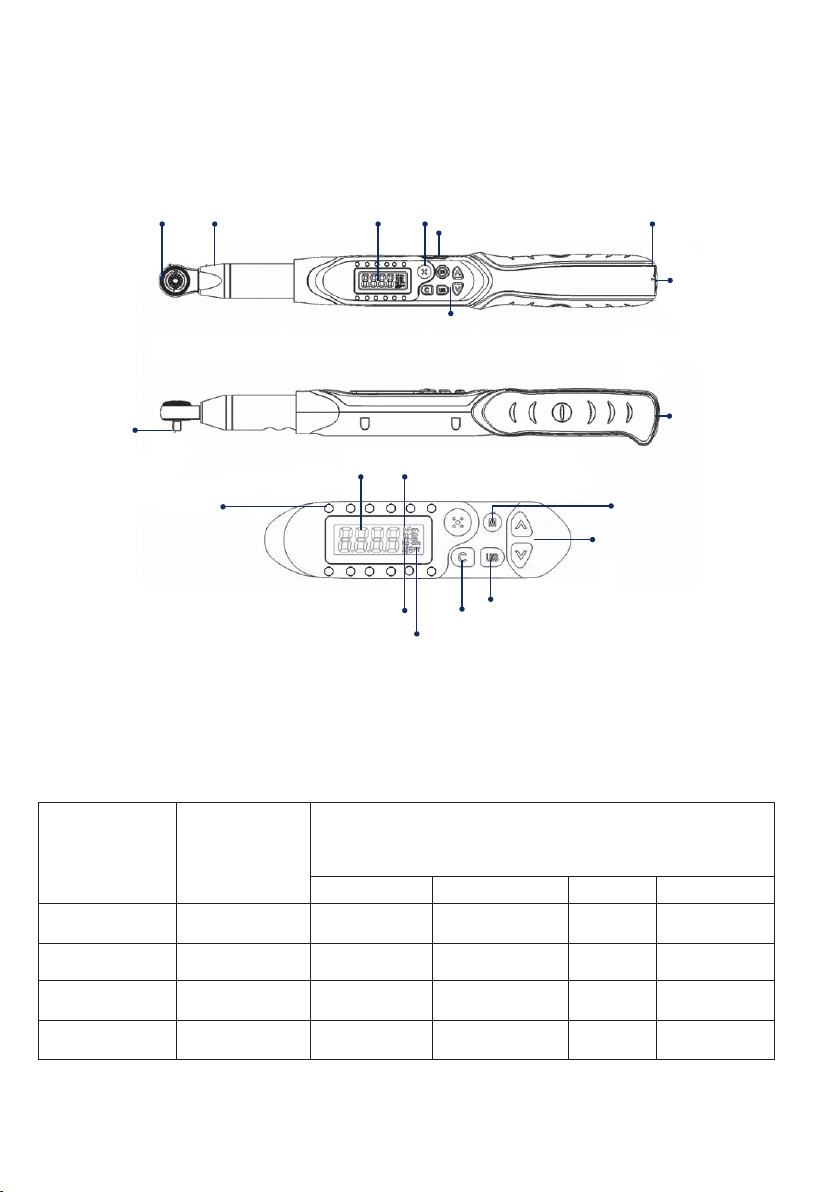

Head type Round head ratchet insert

Size of head of end

fitting (W x H)

9 x 12 mm (7314-2030, 7338-2135)

14 x 18 mm (7312-2200, 7312-2340)

Axial distance 17.5 mm (7314-2030, 7338-2135)

25 mm (7312-2200, 7312-2340)

Gear teeth 52

Battery *3 AA x 2

Operating temperature

-10°C ~ 60°C

Storage temperature -20°C ~ 70°C

Humidity Up to 90% non-condensing

Drop test 1 m

Vibration test *4 10 G

Life time *5 10.000 cycle

Environmental test *6 Pass

Electromagnetic

compatibility test *7 Pass

Note:

*1: The accuracy of the readout is guaranteed

from 20% to 100% of maximum range

+ /- 1 increment.

The torque accuracy is a typical value.

Calibration line is at the middle line of the

dark spot on the rubber handle.

For keeping the accuracy, calibrate the

wrench for a constant period time (1 year).

And the accuracy is based on the zero

degree of offset from perpendicular drive.

*2: Use a special designed cable (accessory) to

upload record data to PC.

*3: Two AA batteries

(Toshiba carbon-zinc battery)

*4: Horizontal and vertical test

*5: One cycle means swing the torque

wrench from 0 Nm to maximum range

and back to 0 Nm.

*6: Environmental test:

a. Dry heat

b. Cold

c. Damp heat

d. Change of temperature

e. Impact (shock)

f. Vibration

g. Drop

*7: Electromagnetic compatibility test:

a. Electrostatic discharge immunity (ESD)

b. Radiated susceptibility

c. Radiated emission