HEATING MAIN MONTAGE INSTRUCTIONS CV4.04

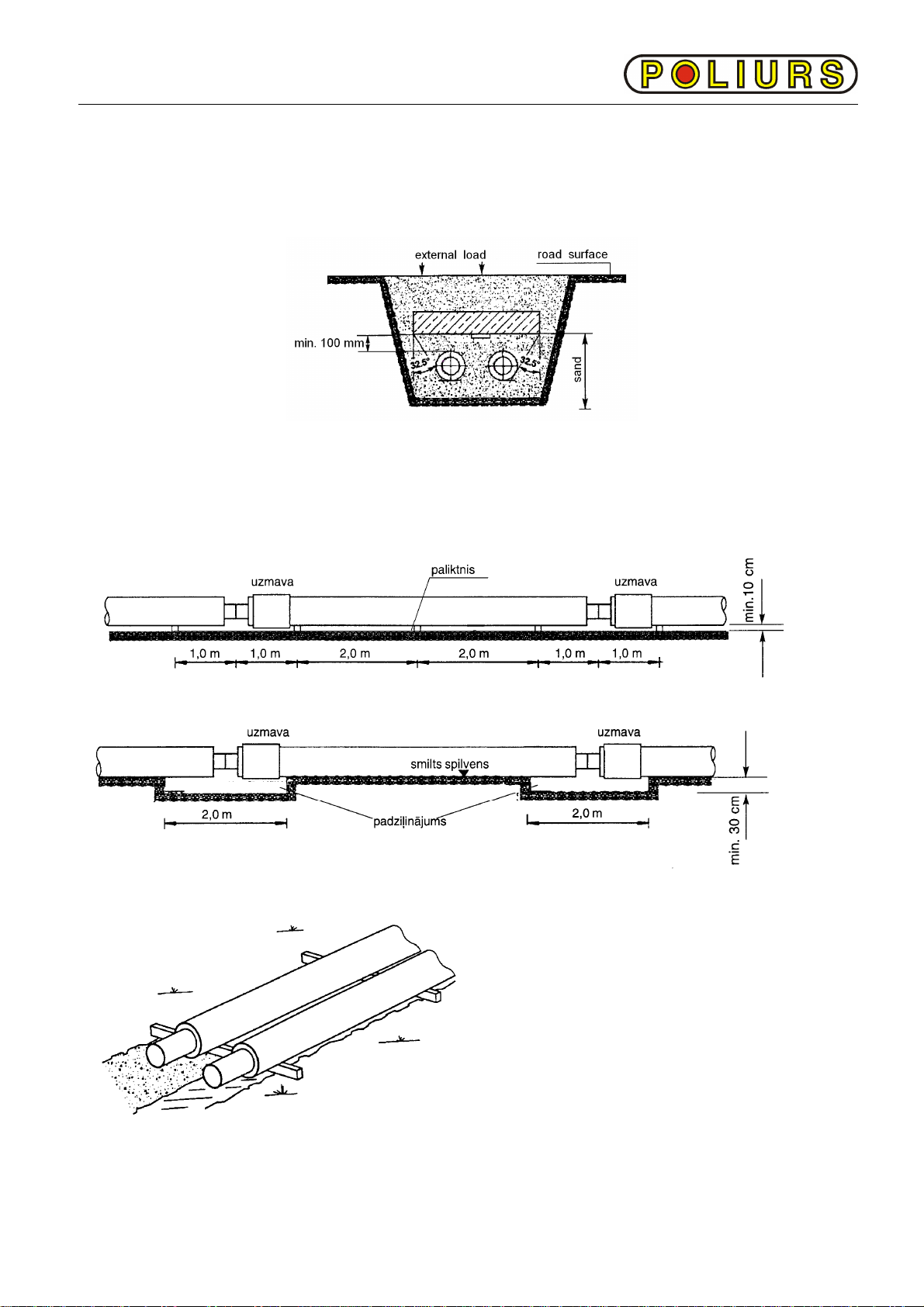

If main heating pipeline is deep enough,

then fitting branch can be placed with an

uplift and then trench will be deeper by H:

H = D + h,

If the depth of the main heating pipeline is

not deep enough, then T-piece should be

diverted to the bottom and piece trench

should be deeper then H.

In places where compensation pillows are

placed, trench width should be increased,

depending on pillow amounts and location.

Trench widening shall comply with

compensation pillow length and thickness.

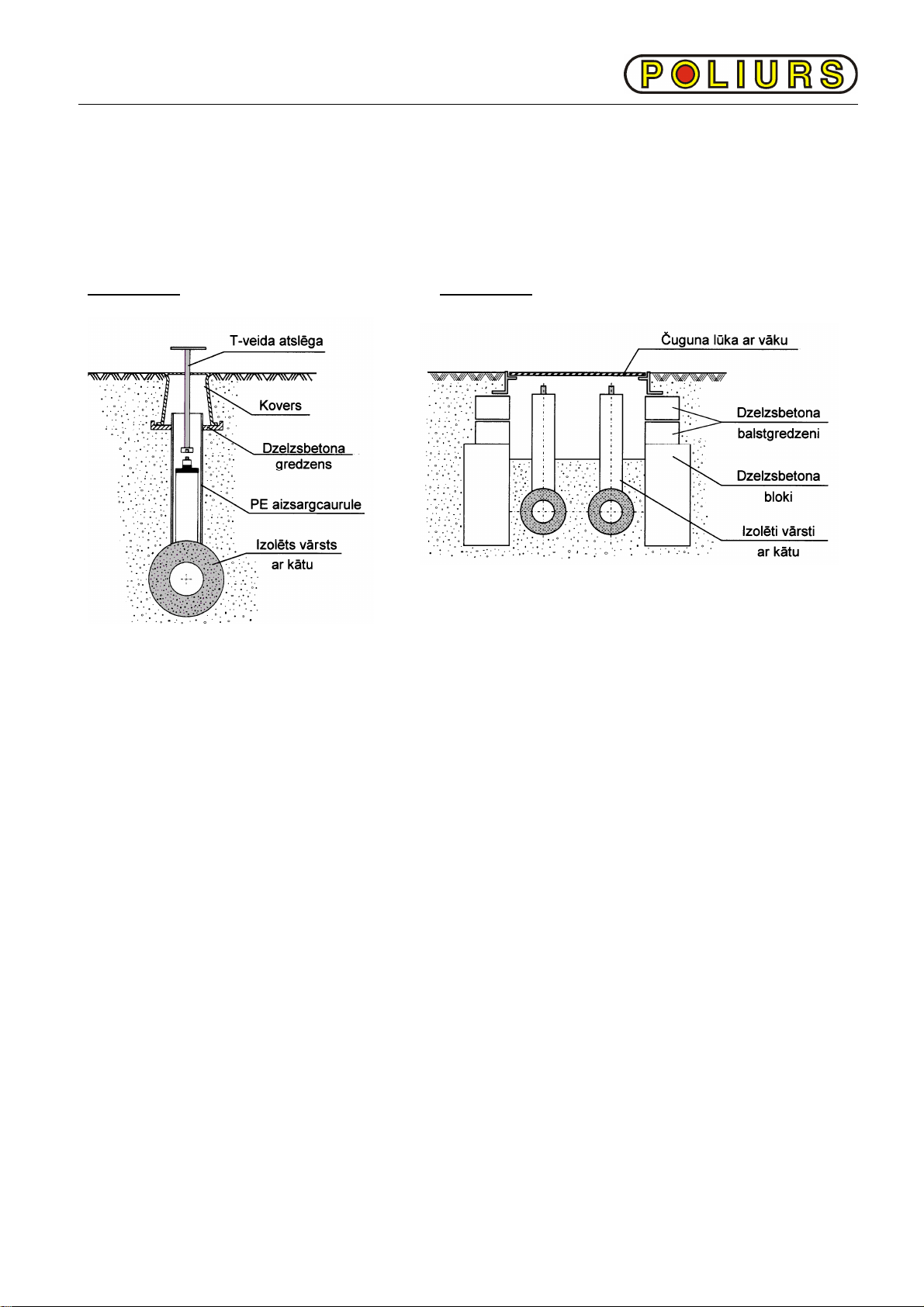

For above ground main pipeline is from

galvanized iron. During montage process

pipes are held together by sliding support.

Pipe is fixed to the sliding support with help

of clamp and non-metallic padding.

The welder should be certified according to the LVS EN 287 standard and according to

technology, which corresponds to LVS EN ISO 15607 demands.

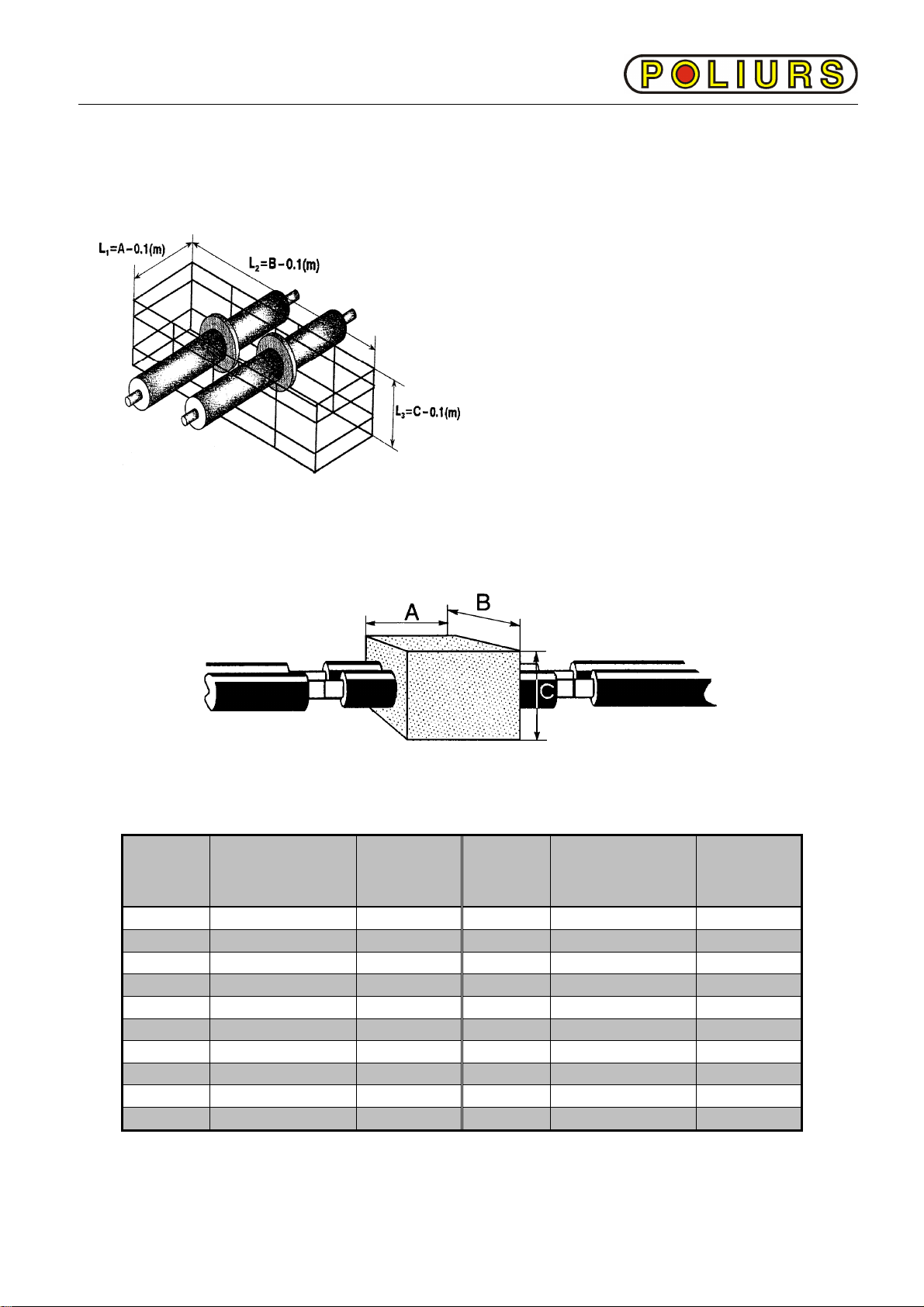

Before steel pipe welding, on cover pipe should be put on cylindrical polyethylene (PE)

sleeves, which are use for connection montage.

To avoid damage of burning of the isolation material, ends of the pipe should be covered

or protected, for example with aluminum protectors. Protective materials should be

removed right after the welding is done and sleeve should get moved over the joining line.

After welding of the steel pipe check PE sleeve before placing it over the joining line.

Before montage, while performing montage and after, it is required so that pipes from

inside would be clean, dry and would not contain any foreign materials.

If after performing montage pipes require cleaning, then rinse them with water.

2.3.